CN111954703A - Laminate for preventing warpage of cured sealing body, and method for producing cured sealing body - Google Patents

Laminate for preventing warpage of cured sealing body, and method for producing cured sealing body Download PDFInfo

- Publication number

- CN111954703A CN111954703A CN201880091671.XA CN201880091671A CN111954703A CN 111954703 A CN111954703 A CN 111954703A CN 201880091671 A CN201880091671 A CN 201880091671A CN 111954703 A CN111954703 A CN 111954703A

- Authority

- CN

- China

- Prior art keywords

- layer

- resin layer

- curable resin

- laminate

- cured

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/20—Adhesives in the form of films or foils characterised by their carriers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J11/00—Features of adhesives not provided for in group C09J9/00, e.g. additives

- C09J11/02—Non-macromolecular additives

- C09J11/06—Non-macromolecular additives organic

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J11/00—Features of adhesives not provided for in group C09J9/00, e.g. additives

- C09J11/08—Macromolecular additives

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J201/00—Adhesives based on unspecified macromolecular compounds

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J5/00—Adhesive processes in general; Adhesive processes not provided for elsewhere, e.g. relating to primers

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/20—Adhesives in the form of films or foils characterised by their carriers

- C09J7/29—Laminated material

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/30—Adhesives in the form of films or foils characterised by the adhesive composition

- C09J7/35—Heat-activated

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/30—Adhesives in the form of films or foils characterised by the adhesive composition

- C09J7/38—Pressure-sensitive adhesives [PSA]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/28—Encapsulations, e.g. encapsulating layers, coatings, e.g. for protection

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/18—Layered products comprising a layer of synthetic resin characterised by the use of special additives

- B32B27/20—Layered products comprising a layer of synthetic resin characterised by the use of special additives using fillers, pigments, thixotroping agents

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Power Engineering (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Physics & Mathematics (AREA)

- Laminated Bodies (AREA)

- Adhesive Tapes (AREA)

- Adhesives Or Adhesive Processes (AREA)

- Sealing Battery Cases Or Jackets (AREA)

- Encapsulation Of And Coatings For Semiconductor Or Solid State Devices (AREA)

- Gasket Seals (AREA)

- Table Devices Or Equipment (AREA)

Abstract

The present invention relates to a laminate for preventing warpage of a cured sealing body, which comprises a curable resin layer (I) comprising a thermosetting resin layer (X1) and a support layer (II) supporting the curable resin layer (I), wherein the thermosetting resin layer (X1) is directly laminated on the support layer (II), the adhesive strength of the 1 st surface of the curable resin layer (I) is 1.7N/25mm or more, which is measured by bonding the 1 st surface to a glass plate at a temperature of 70 ℃, and peeling the curable resin layer (I) at a temperature of 23 ℃, a peeling angle of 180 ℃, and a peeling speed of 300mm/min, the 1 st surface being the surface opposite to the support layer (II), and the cured sealing body is produced by sealing an object to be sealed with a sealing material on the 1 st surface of the curable resin layer (I).

Description

Technical Field

The present invention relates to a laminate for preventing warpage of a cured sealing body, and a method for producing a cured sealing body.

Background

In recent years, electronic devices have been made smaller, lighter, and more functional, and semiconductor chips are sometimes mounted in packages having dimensions close to those of the electronic devices. Such a Package is sometimes called a CSP (Chip Scale Package). The CSP includes: wafer Level Package (WLP) in which a Package is completed by performing a process up to a final packaging process at a Wafer size, Panel Level Package (PLP) in which a Package is completed by performing a process up to a final packaging process at a Panel size larger than a Wafer size, and the like.

WLP and PLP are classified into Fan-In (Fan-In) type and Fan-Out (Fan-Out) type. In fan-out WLP (hereinafter also referred to as "FOWLP") and PLP (hereinafter also referred to as "FOPLP"), a semiconductor chip is covered with a sealing material to form a region larger than the chip size, and a re-wiring layer and an external electrode are formed not only on the circuit surface of the semiconductor chip but also on the surface region of the sealing material to form a cured sealing body of the semiconductor chip.

FOWLP and FOPLP can be manufactured, for example, by the following steps: a mounting step of mounting a plurality of semiconductor chips on the temporary fixing sheet; a coating step of coating the substrate with a thermosetting sealing material; a curing step of obtaining a cured sealing body by thermally curing the sealing material; a separation step of separating the cured sealing body from the temporary fixing sheet; and a rewiring layer forming step of forming a rewiring layer on the exposed surface of the semiconductor chip side (hereinafter, the processing performed in the coating step and the curing step is also referred to as "sealing processing").

Documents of the prior art

Patent document

Patent document 1: japanese patent laid-open No. 2001-131507

Disclosure of Invention

Problems to be solved by the invention

However, if the cured seal is produced using the adhesive sheet described in patent document 1 as a temporary fixing sheet, the cured seal tends to warp due to heat shrinkage. This is believed to be due to: since the semiconductor chip sealed in the cured sealing body is unevenly present on the surface side in contact with the temporary fixing sheet, a region on the side where the semiconductor chip having a small coefficient of thermal expansion is present at a relatively high ratio and a region on the side where the cured resin having a large coefficient of thermal expansion is present at a relatively high ratio are generated in the cured sealing body, and stress is generated due to the difference in thermal shrinkage rate between the two regions. This problem tends to become significant as the package size of FOWLP, FOPLP, or the like increases.

A cured seal that has been warped may cause the following disadvantages: for example, when the cured sealing body is ground in a subsequent step, cracks are likely to occur, and when the cured sealing body is transported by a device, a failure is likely to occur when the cured sealing body is delivered by a robot arm.

In view of the above problems, an object of the present invention is to provide a warpage-preventing laminate which has a support layer and a curable resin layer, can be used for sealing by fixing an object to be sealed to the surface of the curable resin layer, can be provided with a cured resin layer as a warpage-preventing layer to a cured seal body formed by the sealing, and can prevent displacement from occurring when the object to be sealed is fixed, and a method for producing a cured seal body using the warpage-preventing laminate.

Means for solving the problems

The present inventors have conducted intensive studies to solve the above problems, and as a result, have found that the above problems can be solved by setting the adhesive force of the curable resin layer within a predetermined range, and have completed the present invention.

Namely, the present invention provides the following [1] to [11 ].

[1] A laminate for preventing warping of a cured sealing body, comprising:

a curable resin layer (I) comprising a thermosetting resin layer (X1), and

a support layer (II) for supporting the curable resin layer (I),

the thermosetting resin layer (X1) is directly laminated on the support layer (II),

the adhesive strength of the 1 st surface of the curable resin layer (I) is 1.7N/25mm or more, which is measured by bonding the 1 st surface to a glass plate at a temperature of 70 ℃ and peeling the curable resin layer (I) at a temperature of 23 ℃, a peeling angle of 180 ℃ and a peeling speed of 300mm/min, wherein the 1 st surface is the surface opposite to the support layer (II),

the cured sealing body is produced by sealing an object to be sealed with a sealing material on the 1 st surface of the curable resin layer (I).

[2] The laminate for preventing warping according to [1], wherein the curable resin layer (I) is a single thermosetting resin layer (X1).

[3] The laminate for preventing warping according to [1], wherein the curable resin layer (I) comprises a1 st layer located on the side of the support layer (II) and a2 nd layer located on the 1 st surface side,

the 1 st layer is a1 st thermosetting resin layer (X1-1),

the above-mentioned 2 nd layer is a2 nd thermosetting resin layer (X1-2) having a surface adhesion force higher than that of the 1 st thermosetting resin layer (X1-1).

[4] The laminate for preventing warping according to [1], wherein the curable resin layer (I) comprises a1 st layer located on the side of the support layer (II) and a2 nd layer located on the 1 st surface side,

the 1 st layer is a thermosetting resin layer (X1-1),

the 2 nd layer is an energy ray-curable resin layer (X2).

[5] The laminate for preventing warpage according to any one of the above [1] to [4], wherein the thickness of the curable resin layer (I) is 1 to 500 μm.

[6] The laminate for preventing warping according to any one of [1] to [5], wherein,

the support layer (II) has a base material (Y) and an adhesive layer (V), at least one of the base material (Y) and the adhesive layer (V) contains expandable particles,

the anti-warp laminate is separated at the interface between the support layer (II) and the cured resin layer (I') obtained by curing the curable resin layer (I) by the treatment of expanding the expandable particles.

[7] The laminate for preventing warping according to [6], wherein the base material (Y) has an expandable base material layer (Y1) containing the expandable particles.

[8] The laminate for preventing warping according to [7], wherein the pressure-sensitive adhesive layer (V) is a non-expandable pressure-sensitive adhesive layer (V1).

[9] The laminate for preventing warping according to [7] or [8], wherein,

the base material (Y) comprises a non-expandable base material layer (Y2) and an expandable base material layer (Y1),

the support layer (II) comprises a non-expandable base material layer (Y2), an expandable base material layer (Y1) and an adhesive layer (V) in this order,

the adhesive layer (V) and the thermosetting resin layer (X1) were directly laminated together.

[10] A method for producing a cured sealing body, which comprises using the laminate for warpage prevention according to any one of the above items [1] to [9],

the method comprises the following steps:

placing an object to be sealed on a part of the 1 st surface of the curable resin layer (I) included in the laminate for preventing warpage;

coating the object to be sealed and the first surface 1 of the curable resin layer (I) on at least the peripheral portion of the object to be sealed with a thermosetting sealing material;

the sealing material is thermally cured to form a cured sealing body containing the object to be sealed, and the curable resin layer (I) is also thermally cured to form a cured resin layer (I'), thereby obtaining a cured sealing body with a cured resin layer.

[11] A method for producing a cured sealing body, which comprises using the laminate for warpage prevention according to [4] above,

the method comprises the following steps:

placing an object to be sealed on the 1 st surface of the curable resin layer (I) of the warp-preventing laminate, i.e., a part of the surface of the energy ray-curable resin layer (X2) opposite to the 1 st layer;

curing the energy ray-curable resin layer (X2) by irradiation with an energy ray;

coating the object to be sealed and the surface of the curable resin layer (I) on at least the peripheral portion of the object to be sealed with a thermosetting sealing material;

the sealing material is thermally cured to form a cured sealing body containing the object to be sealed, and the curable resin layer (I) is also thermally cured to form a cured resin layer (I'), thereby obtaining a cured sealing body with a cured resin layer.

ADVANTAGEOUS EFFECTS OF INVENTION

According to the present invention, it is possible to provide a warpage-preventing laminate which can be sealed by fixing an object to be sealed to the surface of the curable resin layer, can provide a cured resin layer as a warpage-preventing layer to the cured seal body formed by the sealing, and can prevent displacement from occurring when the object to be sealed is fixed, and a method for manufacturing a cured seal body using the warpage-preventing laminate.

Drawings

Fig. 1 is a schematic cross-sectional view of a warp-preventing laminate according to a first embodiment of the present invention.

Fig. 2 is a schematic cross-sectional view of a laminate for warpage prevention, showing the structure of the laminate according to a second embodiment of the present invention.

Fig. 3 is a schematic cross-sectional view of a warp-preventing laminate according to a third embodiment of the present invention.

Fig. 4 is a schematic cross-sectional view of a warp-preventing laminate according to a fourth embodiment of the present invention.

Fig. 5 is a schematic cross-sectional view of a laminate for preventing warping according to a fifth embodiment of the present invention.

FIG. 6 is a schematic sectional view showing a step of producing a cured sealing body with a cured resin layer.

FIG. 7 is a schematic sectional view showing another manufacturing process of a cured sealing body with a cured resin layer.

Description of the symbols

(I) The method comprises the following steps Curable resin layer

(I'): cured resin layer

(I*): partially cured curable resin layer

(II): supporting layer

(II'): expanded support layer

(V): adhesive layer

(V1): (1 st) adhesive layer

(V1-1): 1 st adhesive layer

(V2), (V1-2): 2 nd adhesive layer

(X1), (X1-1), (X1-2): thermosetting resin layer

(X1'): cured thermosetting resin layer

(X1-1'): cured thermosetting resin layer

(X2): energy ray-curable resin layer

(X2'): cured energy ray-curable resin layer

(Y): base material

(Y1): expandable substrate layer

(Y1'): expanded expandable base material layer

(Y2): non-expandable substrate layer

1a, 1b, 2a, 2b, 3,4, 5: anti-warping laminate

50: support body

60: sealing object (semiconductor chip)

70: forming die

71: injection hole

72: shaping space

80: sealing material

81: cured sealing material

85: cured seal

200: cured sealing body with cured resin layer

P: interface (I)

Detailed Description

First, terms used in the present specification will be described.

In the present specification, whether or not the layer to be evaluated is a "non-expandable layer" can be determined as follows: after the treatment for swelling was performed for 3 minutes, when the volume change rate before and after the treatment was less than 5% as calculated from the following equation, the layer was determined to be a "non-swelling layer". On the other hand, when the volume change rate is 5% or more, the layer is determined to be an "expandable layer".

Volume change rate (%) { (volume of the layer after treatment-volume of the layer before treatment)/volume of the layer before treatment } × 100

In the case of a layer containing thermally expandable particles, for example, the "treatment for expanding" may be performed by performing a heating treatment for 3 minutes at an expansion start temperature (t) of the thermally expandable particles.

In the present specification, the "active ingredient" refers to a component other than the diluting solvent among the components contained in the target composition.

In the present specification, the weight average molecular weight (Mw) is a value in terms of standard polystyrene measured by a Gel Permeation Chromatography (GPC) method, specifically a value measured by the method described in examples.

In the present specification, for example, "(meth) acrylic acid" means both "acrylic acid" and "methacrylic acid", and other similar terms are also used.

In the present specification, regarding a preferable numerical range (for example, a range of contents), the lower limit value and the upper limit value described in sections may be independently combined. For example, according to the description of "preferably 10 to 90, more preferably 30 to 60", the "preferable lower limit value (10)" and the "more preferable upper limit value (60)" may be combined to obtain "10 to 60".

In the present specification, the "energy ray" means a ray having an energy quantum in an electromagnetic wave or a charged particle beam, and examples thereof include ultraviolet rays, radiation, an electron beam, and the like. The ultraviolet rays can be irradiated using, for example, a high-pressure mercury lamp, a fusion lamp, a xenon lamp, a black light, an LED lamp, or the like as an ultraviolet light source. The electron beam may irradiate an electron beam generated by an electron beam accelerator or the like.

In the present specification, "energy ray-curable property" means a property that curing occurs by irradiation with an energy ray, and "non-energy ray-curable property" means a property that curing does not occur even if irradiation with an energy ray.

Hereinafter, embodiments of the present invention (hereinafter, also referred to as "the present embodiment") will be described.

[ anti-warping laminate ]

The laminate for preventing warpage according to one embodiment of the present invention includes a curable resin layer (I) including a thermosetting resin layer (X1), and a support layer (II) that supports the curable resin layer (I). In the following description, the laminate for preventing warpage may be simply referred to as "laminate".

The thermosetting resin layer (X1) is directly laminated on the support layer (II).

The adhesive strength of the 1 st surface, which is the surface of the curable resin layer (I) opposite to the support layer (II), is 1.7N/25mm or more, as measured by bonding the 1 st surface to a glass plate at a temperature of 70 ℃ and peeling the curable resin layer (I) at a temperature of 23 ℃, a peeling angle of 180 ℃ and a peeling speed of 300 mm/min.

The laminate for preventing warpage is used for sealing an object to be sealed with a sealing material on the 1 st surface of the curable resin layer (I) to produce a cured sealing body, and serves to prevent warpage of the cured sealing body during the production process.

< construction of laminate for preventing warpage >

The structure of the laminate for preventing warping according to the present embodiment will be described with reference to the drawings.

Fig. 1 to 5 are schematic cross-sectional views of a laminate for preventing warping according to first to fifth embodiments of the present invention. In the laminate of the first to fifth embodiments below, a release material may be further laminated on the pressure-sensitive adhesive surface of the pressure-sensitive adhesive layer (V1) bonded to a support (not shown) and the 1 st surface (surface opposite to the support layer (II)) of the curable resin layer (I) from the viewpoint of protecting the surfaces of the curable resin layer (I) and the support layer (II). The release material can be peeled and removed when the warp-preventing laminate is used.

[ anti-warping laminate according to the first embodiment ]

As the laminate for preventing warpage according to the first embodiment of the present invention, laminates 1a and 1b shown in fig. 1 can be exemplified.

The laminated bodies 1a and 1b have the following structure: the adhesive layer comprises a support layer (II) having a substrate (Y) and an adhesive layer (V1), and a curable resin layer (I), wherein the substrate (Y) and the curable resin layer (I) are directly laminated together.

In the following description, the surface of the curable resin layer (I) opposite to the support layer (II) may be referred to as "1 st surface", and the surface on the support layer (II) side may be referred to as "2 nd surface".

The 1 st surface of the curable resin layer (I) is an adhesive surface having a predetermined adhesive force, and when the object to be sealed is placed, the object to be sealed can be fixed by the adhesive force.

In the laminates 1a and 1b, the adhesive surface of the pressure-sensitive adhesive layer (V1) is bonded to a support (not shown).

In the support layer (II), both the substrate (Y) and the pressure-sensitive adhesive layer (V1) may be non-expandable, or at least either one of the substrate (Y) and the pressure-sensitive adhesive layer (V1) may be an expandable layer, and preferably either one of the layers contains expandable particles and has expandability. In the laminate 1a of fig. 1(a), the base material (Y) has an expandable base material layer (Y1) containing expandable particles.

The substrate (Y) may be a single-layer structure substrate composed only of an expandable substrate layer (Y1) such as the laminate 1a shown in fig. 1(a), or may be a multilayer structure substrate having an expandable substrate layer (Y1) and a non-expandable substrate layer (Y2) such as the laminate 1b shown in fig. 1 (b).

In the case where the substrate (Y) having the expandable substrate layer (Y1) and the non-expandable substrate layer (Y2) is used in the laminate for preventing warping according to the first embodiment, it is preferable that the laminate have a structure in which the non-expandable substrate layer (Y2) is laminated on the surface of the pressure-sensitive adhesive layer (V1) and the expandable substrate layer (Y1) is further laminated on the surface of the non-expandable substrate layer (Y2), as shown in fig. 1 (b).

In the laminate 1a shown in fig. 1(a), the expandable particles contained in the expandable base material layer (Y1) expand by expansion treatment by heating or the like, and irregularities are generated on the surface of the base material (Y), and the contact area with the cured resin layer obtained by curing the curable resin layer (I) decreases. In the following description, a layer obtained by curing a curable resin layer is referred to as a cured resin layer (I').

At this time, the adhesive surface of the adhesive layer (V1) is stuck to a support (not shown). By attaching the pressure-sensitive adhesive layer (V1) to the support in a sufficiently adhesive manner, even if a force that would cause unevenness is generated on the surface of the expandable base material layer (Y1) on the pressure-sensitive adhesive layer (V1) side, a force that repels the pressure-sensitive adhesive layer (V1) is likely to be generated. Therefore, unevenness is less likely to be formed on the surface of the substrate (Y) on the pressure-sensitive adhesive layer (V1) side.

As a result, the laminate 1a can be easily separated at a time with a small force at the interface P between the base (Y) of the support layer (II) and the cured resin layer (I').

By forming the pressure-sensitive adhesive layer (V1) of the laminate 1a with a pressure-sensitive adhesive composition that can increase the adhesive strength to the support, separation at the interface P can be performed more easily. In the following description, the interface between the curable resin layer (I) and the support layer (II) may be referred to as "interface P".

In order to prevent the stress due to the expandable particles from being transmitted to the pressure-sensitive adhesive layer (V1), it is preferable that the base material (Y) have an expandable base material layer (Y1) and a non-expandable base material layer (Y2) as in the laminate 1b shown in fig. 1 (b).

Since the stress of the expandable base material layer (Y1) due to expansion of the expandable particles is suppressed by the non-expandable base material layer (Y2), it is not easily transmitted to the adhesive layer (V1).

Therefore, unevenness is less likely to occur on the surface of the pressure-sensitive adhesive layer (V1) on the support side, and the adhesion between the pressure-sensitive adhesive layer (V1) and the support is hardly changed before and after the expansion treatment by heating or the like, and good adhesion can be maintained. As a result, irregularities are easily formed on the surface of the expandable substrate layer (Y1) on the curable resin layer (I) side, and as a result, the expandable substrate layer (Y1) of the support layer (II) and the cured resin layer (I') can be easily separated at a time with a small force.

As in the laminate 1b shown in fig. 1(b), the expandable base material layer (Y1) and the curable resin layer (I) are preferably directly laminated, and the pressure-sensitive adhesive layer (V1) is preferably laminated on the surface of the non-expandable base material layer (Y2) opposite to the curable resin layer (I).

Further, an adhesive layer and an anchor layer for bonding the expandable base material layer (Y1) and the non-expandable base material layer (Y2) may be provided between them, or they may be directly laminated.

[ laminate for preventing warping in the second embodiment ]

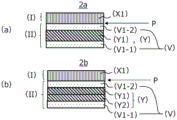

As the laminate for preventing warping according to the second embodiment of the present invention, the laminates 2a and 2b for preventing warping shown in fig. 2 can be exemplified.

The laminated bodies 2a and 2b have the following structure: the adhesive layer of the support layer (II) has a1 st adhesive layer (V1-1) and a2 nd adhesive layer (V1-2), the substrate (Y) is sandwiched between the 1 st adhesive layer (V1-1) and the 2 nd adhesive layer (V1-2), and the adhesive surface of the 2 nd adhesive layer (V1-2) is directly laminated with the curable resin layer (I). Hereinafter, each pressure-sensitive adhesive layer in the case where the support layer (II) includes a plurality of pressure-sensitive adhesive layers, and the pressure-sensitive adhesive layer in the case where the support layer (II) includes a single pressure-sensitive adhesive layer may be collectively referred to as a pressure-sensitive adhesive layer (V).

In the laminate for preventing warping according to the second embodiment, the adhesive surface of the 1 st adhesive layer (V1-1) is bonded to a support (not shown).

In the laminate for preventing warpage of the second embodiment, the base material (Y) preferably has a swellable base material layer (Y1) containing swellable particles.

The substrate (Y) may be a single-layer structure substrate composed only of an expandable substrate layer (Y1) such as the laminate 2a shown in fig. 2(a), or may be a multilayer structure substrate having an expandable substrate layer (Y1) and a non-expandable substrate layer (Y2) such as the laminate 2b shown in fig. 2 (b).

However, as described above, from the viewpoint of forming a laminate in which the adhesion between the 1 st pressure-sensitive adhesive layer (V1-1) and the support can be kept good before and after the expansion treatment by heating or the like, it is preferable that the base material (Y) has an expandable base material layer (Y1) and a non-expandable base material layer (Y2), as shown in fig. 2 (b).

In the case where the substrate (Y) having the expandable substrate layer (Y1) and the non-expandable substrate layer (Y2) is used in the laminate for preventing warpage according to the second embodiment, it is preferable that the laminate have a structure in which the 2 nd pressure-sensitive adhesive layer (V1-2) is laminated on the surface of the expandable substrate layer (Y1) and the 1 st pressure-sensitive adhesive layer (V1-1) is laminated on the surface of the non-expandable substrate layer (Y2), as shown in fig. 2 (b).

In the laminate of the second embodiment, the expandable particles in the expandable base material layer (Y1) constituting the base material (Y) are expanded by expansion treatment by heating or the like, and irregularities are generated on the surface of the expandable base material layer (Y1).

Furthermore, the 2 nd pressure-sensitive adhesive layer (V1-2) was pushed up by the irregularities generated on the surface of the expandable base material layer (Y1), and irregularities were also formed on the bonding surface of the 2 nd pressure-sensitive adhesive layer (V1-2), so that the contact area between the 2 nd pressure-sensitive adhesive layer (V1-2) and the cured resin layer (I') was reduced. As a result, the interface P between the 2 nd adhesive layer (V1-2) of the support layer (II) and the cured resin layer (I') can be easily separated at a time with a small force.

In the laminate of the second embodiment, from the viewpoint of obtaining a laminate that can be separated at once and easily with a small force at the interface P, a configuration in which the expandable base layer (Y1) of the base material (Y) of the support layer (II) and the 2 nd pressure-sensitive adhesive layer (V1-2) are directly laminated together is preferable.

[ anti-warping laminate according to third embodiment ]

As a laminate for preventing warping according to a third embodiment of the present invention, a laminate 3 for preventing warping shown in fig. 3 can be exemplified.

The laminate 3 shown in fig. 3 has the following structure: the adhesive sheet is provided with a support layer (II) which has a1 st adhesive layer (V1) which is a non-expandable adhesive layer on the surface side of one side of a substrate (Y) and a2 nd adhesive layer (V2) which is an expandable adhesive layer containing expandable particles on the surface side of the other side of the substrate (Y), wherein the 2 nd adhesive layer (V2) and a curable resin layer (I) are directly laminated together.

In the laminate 3, the adhesive surface of the 1 st adhesive layer (V1) is bonded to a support (not shown).

The base material (Y) of the laminate 3 according to the third embodiment is preferably composed of a non-swelling base material layer (Y2).

In the laminate 3 of the third embodiment, the expandable particles in the 2 nd adhesive layer (V2) which is an expandable adhesive layer are expanded by expansion treatment such as heating, and irregularities are generated on the surface of the 2 nd adhesive layer (V2), and the contact area between the 2 nd adhesive layer (V2) and the curable resin layer (I) is reduced.

On the other hand, since the surface of the 1 st pressure-sensitive adhesive layer (V1) on the substrate (Y) side is laminated on the substrate (Y), unevenness is less likely to occur.

Therefore, unevenness is easily formed on the surface of the 2 nd adhesive layer (V2) on the curable resin layer (I) side by expansion treatment such as heating, and as a result, separation can be easily performed at a time with a small force at the interface P between the 2 nd adhesive layer (V2) and the cured resin layer (I') of the support layer (II).

[ anti-warping laminate according to fourth embodiment ]

As a laminate for preventing warpage according to a fourth embodiment of the present invention, a laminate 4 for preventing warpage shown in fig. 4 can be cited.

The laminate 4 shown in fig. 4 has a structure in which a non-expandable pressure-sensitive adhesive layer (V1), an expandable base material layer (Y1), and a curable resin layer (I) are sequentially laminated.

In the laminate 4, the curable resin layer (I) is composed of a curable resin layer (I) including a1 st thermosetting resin layer (X1-1) located on the substrate (Y) side and a2 nd thermosetting resin layer (X1-2) located on the opposite side of the substrate (Y). The 1 st thermosetting resin layer (X1-1) and the 2 nd thermosetting resin layer (X1-2) are both non-swelling.

Here, the adhesion force of the surface of the 2 nd thermosetting resin layer (X1-2) is higher than that of the 1 st thermosetting resin layer (X1-1). In the laminate 4, the curable resin layer (I) is formed of 2 thermosetting resin layers, whereby layers having different characteristics can be used. For example, a thermosetting resin layer containing a composition having a higher adhesiveness may be selected as the curable resin layer on the side opposite to the support layer (II), and a layer having a better separability from the support layer (II) may be selected as the curable resin layer on the side of the support layer (II).

[ laminate for preventing warping in fifth embodiment ]

As the laminate for preventing warping according to the fifth embodiment of the present invention, a laminate for preventing warping 5 shown in fig. 5 can be exemplified.

The laminate 5 shown in fig. 5 has a structure in which a non-expandable pressure-sensitive adhesive layer (V1), an expandable base material layer (Y1), and a curable resin layer (I) are sequentially laminated.

In the laminate 5, the curable resin layer (I) is composed of a curable resin layer (I) including a thermosetting resin layer (X1-1) located on the substrate (Y) side and an energy ray curable resin layer (X2) located on the opposite side of the substrate (Y). The 1 st thermosetting resin layer (X1-1) and the energy ray-curable resin layer (X2) are both non-expandable.

In the laminate 5, the curable resin layer (I) is divided into the energy ray-curable resin layer (X2) and the thermosetting resin layer (X1-1), whereby layers having different properties can be used. For example, an energy-curable resin layer made of an energy ray-curable composition which can be easily adjusted to have a high adhesive force may be disposed on the opposite side of the support layer (II), and a thermosetting resin layer having a more excellent separability from the sealing material described later may be disposed on the support layer (II).

[ use of a laminate for preventing warping ]

The laminate for preventing warpage of the present embodiment can be used for producing a cured sealing body as follows: an object to be sealed is placed on the surface of the curable resin layer, and the object to be sealed and the surface of the thermosetting resin layer in at least the peripheral portion of the object to be sealed are covered with a sealing material, and the sealing material is cured to obtain a cured sealing body including the object to be sealed.

The following is a description of a specific embodiment of the production of a cured sealing body using the warpage preventing laminate.

For example, a case may be considered in which the following is adopted in the manufacturing method described in patent document 1: after a sealing object is placed on the bonding surface of a conventional adhesive laminate such as a die attach tape, the sealing object and the bonding surface of the peripheral portion thereof are covered with a sealing material, and the sealing material is thermally cured to produce a cured sealing body.

When the sealing material is thermally cured, stress that causes shrinkage of the sealing material acts, but since the adhesive laminate is fixed to the support, stress of the sealing material is suppressed.

However, it is difficult to suppress stress that causes shrinkage of the cured sealing body obtained by separation from the support and the adhesive laminate. Since the amount of the sealing material present in the cured sealing body after separation is different between the surface side on which the object to be sealed is present and the surface side opposite thereto, a difference in shrinkage stress is likely to occur. This difference in shrinkage stress causes warpage of the cured sealing body.

In addition, from the viewpoint of productivity, generally, the cured sealing body after heating is separated from the support and the adhesive laminate in a state of being heated to some extent. Therefore, after the separation, the sealing material is also cured, and shrinkage due to natural cooling occurs, so that the cured sealing body is more likely to be warped.

On the other hand, when the laminate for preventing warpage according to one embodiment of the present invention is used, a cured sealing body in which warpage is effectively suppressed can be obtained for the following reasons.

That is, when the object to be sealed is placed on the surface of the thermosetting resin layer of the laminate for warpage prevention according to the embodiment of the present invention, and the sealing material is coated with the sealing material and then the sealing material is thermally cured, the thermosetting resin layer is also thermally cured at the same time. In this case, since the thermosetting resin layer is provided on the surface side on the side where the object to be sealed is present, where the amount of the sealing material present is small and the shrinkage stress due to curing of the sealing material is considered to be small, the shrinkage stress due to thermosetting of the thermosetting resin layer acts.

As a result, it is considered that the difference in the shrinkage stress between 2 surfaces of the cured sealing body can be reduced, and the cured sealing body in which the warpage is effectively suppressed can be obtained.

In addition, the thermosetting resin layer contributing to suppression of warpage of the cured sealing body can be formed into a cured resin layer by heat curing.

That is, since the cured resin layer can be formed on one surface of the cured sealing body at the same time by using the laminate for warpage prevention according to the embodiment of the present invention and performing the sealing step, a step for forming the cured resin layer can be omitted, which contributes to improvement of productivity.

Further, the curable resin layer (I) in the laminate for warpage prevention according to an embodiment of the present invention is a layer containing a curable resin composition, but since the surface thereof has a high adhesive force of 1.7N/25mm or more, when an object to be sealed is fixed to the surface of the curable resin layer (I), the object to be sealed can be prevented from being displaced.

< various physical Properties of laminate >

(adhesive force of the 1 st surface of the curable resin layer (I))

In the laminate according to one embodiment of the present invention, the surface (1 st surface) of the curable resin layer (I) on which the object to be sealed is placed has adhesiveness in order to improve adhesion to the object to be sealed.

The adhesive strength of the 1 st surface of the curable resin layer (I) is 1.7N/25mm or more, preferably 2.3N/25mm or more, more preferably 3.0N/25mm or more, further preferably 4.0N/25mm or more, further preferably 20N/25mm or less, more preferably 15N/25mm or less, further preferably 10N/25mm or less, as measured by bonding the 1 st surface to a glass plate at a temperature of 70 ℃ and peeling the curable resin layer at a peeling angle of 180 ℃ and a peeling speed of 300 mm/min.

If the adhesive force of the 1 st surface of the curable resin layer (I) is less than 1.7N/25mm, the object to be sealed may be displaced when the object to be sealed is fixed to the surface of the curable resin layer (I). When the adhesive force of the 1 st surface of the curable resin layer (I) is 20N/25mm or less, the material of the curable resin layer (I) can be easily selected.

(shear force of curable resin layer (I))

In the laminate according to one embodiment of the present invention, the curable resin layer (I) preferably has an appropriate shear force from the viewpoint of maintaining the object to be sealed well when the object to be sealed is sealed. Specifically, the shear strength of the curable resin layer (I) with respect to the adherend for measurement is preferably 20N/(3mm × 3mm) or more, more preferably 25N/(3mm × 3mm), still more preferably 30N/(3mm × 3mm) or more, and further preferably 100N/(3mm × 3mm) or less, more preferably 90N/(3mm × 3mm) or less, and the shear strength is a value measured when a silicon chip (mirror surface) having a thickness of 350 μm and a size of 3mm × 3mm is used as the adherend for measurement, the mirror surface of the adherend for measurement is pressed at a temperature of 70 ℃ for 1 second at 130gf to adhere to the curable resin layer, and the measurement is performed at a speed of 200 μm/s.

When the shear strength of the curable resin layer (I) to the adherend for measurement is 20N/(3mm × 3mm) or more, when the object to be sealed is fixed to the surface of the curable resin layer (I) and the object to be sealed is covered with the sealing material, the object to be sealed can be prevented from being displaced or inclined due to the flow of the sealing material. When the shear strength is 100N/(3 mm. times.3 mm) or less, the material of the curable resin layer (I) can be easily selected.

(adhesive force of thermosetting resin layer (X1))

In the laminate of one embodiment of the present invention, the adhesive strength of the thermosetting resin layer (I) alone at room temperature (23 ℃) is preferably 0.1 to 10.0N/25mm, more preferably 0.2 to 8.0N/25mm, further preferably 0.4 to 6.0N/25mm, and further preferably 0.5 to 4.0N/25 mm.

In the case of having the 1 st thermosetting resin layer (X1-1) and the 2 nd thermosetting resin layer (X1-2) as in the laminate 4 shown in FIG. 4, each of them preferably has the above adhesive force, and particularly, the adhesive force of the 2 nd thermosetting resin layer (X1-2) is preferably higher than that of the 1 st thermosetting resin layer (X1-1). By making the adhesive force of the 2 nd thermosetting resin layer (X1-2) higher than the adhesive force of the 1 st thermosetting resin layer (X1-1), the object to be sealed can be more reliably fixed to the 1 st surface of the curable resin layer (I).

(adhesive force of energy ray-curable resin layer (X2))

In the laminate according to one embodiment of the present invention, the adhesive strength of the energy ray curable resin layer (X2) alone at room temperature (23 ℃) is preferably 0.1 to 10.0N/25mm, more preferably 0.2 to 8.0N/25mm, still more preferably 0.4 to 6.0N/25mm, and still more preferably 0.5 to 4.0N/25 mm.

(adhesive force of adhesive layer (V))

In the laminate according to one embodiment of the present invention, the adhesive strength of the adhesive layer (V) (the 1 st adhesive layer (V1) and the 2 nd adhesive layer (V2)) of the support layer (II) at room temperature (23 ℃) is preferably 0.1 to 10.0N/25mm, more preferably 0.2 to 8.0N/25mm, still more preferably 0.4 to 6.0N/25mm, and still more preferably 0.5 to 4.0N/25 mm. In the following description, the pressure-sensitive adhesive layer on the side of the curable resin layer (I) may be referred to as the 1 st pressure-sensitive adhesive layer and the pressure-sensitive adhesive layer on the opposite side of the curable resin layer may be referred to as the 2 nd pressure-sensitive adhesive layer, regardless of whether the pressure-sensitive adhesive layer is a single pressure-sensitive adhesive layer or a plurality of pressure-sensitive adhesive layers.

In the case where the support layer (II) has the 1 st adhesive layer (V1-1) or (V1) and the 2 nd adhesive layer (V1-2) or (V2), the adhesive forces of the 1 st adhesive layer (V1-1) or (V1) and the 2 nd adhesive layer (V1-2) or (V2) are preferably within the above ranges, respectively, but from the viewpoint of improving the adhesion to the support and enabling separation at the interface P at a time and more easily, the adhesive force of the 1 st adhesive layer (V1-1) or (V1) to be bonded to the support is more preferably higher than the adhesive force of the 2 nd adhesive layer (V1-2) or (V2).

(measurement of adhesive force on the 1 st surface of the curable resin layer (I))

In the present specification, the adhesive force of the 1 st surface of the curable resin layer (I) can be measured in the following order.

First, a laminate for warpage prevention comprising a curable resin layer (I) and a support layer (II) was cut into a width of 25mm × a length of 250mm (250 mm in the MD direction) to prepare a primary sample. Further, a glass plate (3mm float glass plate manufactured by U-Kou Co., Ltd. (JIS R3202) was prepared) as an adherend. A glass plate was attached to the first surface of the curable resin layer (I) in direct contact therewith using a laminating apparatus (manufactured by Taisei Laminator Co., Ltd., model VA-400) to obtain a test piece. In this case, the roller temperature was set to 70 ℃ and the application speed was set to 0.2 m/min. The thus-obtained test piece was left to stand in an environment of 23 ℃ and 50% RH (relative humidity) for 24 hours, and then the test piece was peeled from the glass plate under conditions of a peeling angle of 180 ° and a peeling speed of 300mm/min and a peeling temperature of 23 ℃ by a tensile load measuring machine (TENSILON, manufactured by a & D company) based on JIS Z0237:2000 in the same environment, and the adhesive force thereof was measured, and the measured value was taken as the adhesive force of the 1 st surface of the curable resin layer (I).

(measurement of shear force of curable resin layer (I))

In the present specification, the shear force of the curable resin layer (I) can be measured in the following order.

First, a silicon chip having a thickness of 350 μm and provided with a mirror surface of 3mm × 3mm was used as an adherend for measurement. Then, the first surface of the curable resin layer (I) of each laminate obtained in each example and comparative example described later was adhered by pressing the mirror surface of the adherend for measurement at a temperature of 70 ℃ for 1 second at 130 gf. Next, the shear force was measured at a speed of 200 μm/s using a universal type push-pull force tester (manufactured by Nordson Advanced Technology, Inc., DAGE 4000).

(measurement of adhesive force of adhesive layer (V), thermosetting resin layer (X1), and energy ray-curable resin layer (X2))

An adhesive tape (product name "PL chip" manufactured by linkeko corporation) was laminated on the surface of the adhesive layer (V), the thermosetting resin layer (X1), or the energy ray curable resin layer (X2) formed on the release film.

Then, the surface of the pressure-sensitive adhesive layer (V), the thermosetting resin layer (X1), or the energy ray-curable resin layer (X2) exposed after the release film was peeled off was bonded to a glass plate (3mm float glass plate manufactured by U-Kou, Inc. (JIS R3202)). At this time, the temperature for bonding the pressure-sensitive adhesive layer (V) was set to 23 ℃ and the temperature for bonding the thermosetting resin layer (X1) and the energy ray-curable resin layer (X2) was set to 70 ℃. Further, the glass plate to which each layer was attached was left to stand in an environment of 23 ℃ and 50% RH (relative humidity) for 24 hours, and then the pressure-sensitive adhesive layer (V), the thermosetting resin layer (X1), or the energy ray-curable resin layer (X2) was peeled from the glass plate together with the pressure-sensitive adhesive tape at a tensile rate of 300mm/min by a 180 ° peeling method based on JIS Z0237:2000 in the same environment, thereby measuring the adhesive force at 23 ℃.

(peeling force (F) before expansion treatment0))

From the viewpoint of sufficiently fixing the object to be sealed before curing and before expansion treatment of the curable resin layer (I) so as not to adversely affect the sealing operation, it is preferable that the adhesion between the support layer (II) and the curable resin layer (I) is high.

From the above-described viewpoint, in the laminate according to one embodiment of the present invention, the peeling force (F) is obtained when the interface P between the support layer (II) and the curable resin layer (I) is separated before the curable resin layer (I) is cured and before the thermal expansion treatment is performed0) Preferably 100mN/25mm or more, more preferably 130mN/25mm or more, further preferably 160mN/25mm or more, and further preferably 50,000mN/25mm or less.

The peel force (F)0) Is a value measured by the following measurement method.

(peeling force (F)0) Measurement of (2)

The laminate was left to stand in an atmosphere of 23 ℃ and 50% RH (relative humidity) for 24 hours, and then the support layer (II) side of the laminate was bonded to a glass plate (3mm float glass plate (JIS R3202 product) manufactured by U-Kou Kyowa K.) through an adhesive layer. Further, an adhesive tape (product name "PL chip", manufactured by linkeko corporation) was attached to the 1 st surface side of the laminate. Then, the end of the glass plate to which the laminate was attached was fixed to a lower chuck of a universal tensile testing machine (product name "TENSILON UTM-4-100", manufactured by Orientec Co., Ltd.).

Next, the end of the adhesive tape bonded to the curable resin layer (I) of the laminate was fixed with an upper chuck of a universal tensile testing machine so that the separation occurred at the interface P between the support layer (II) and the curable resin layer (I) of the laminate. Then, the peel force measured when the curable resin layer (I) and the adhesive tape were peeled from the support layer (II) at the interface P by a 180 ℃ peel method at a tensile rate of 300mm/min in the same environment as described above based on JIS Z0237:2000 was regarded as "peel force (F)0)”。

(peeling force after swelling treatment (F)1))

In the laminate according to one embodiment of the present invention, the support layer (II) and the curable resin layer (I) or the cured resin layer (I') obtained by curing the curable resin layer (I) can be separated at a time and easily by swelling treatment with a small force at the interface P therebetween.

Here, in the laminate according to an embodiment of the present invention, the peeling force (F) is obtained when the curable resin layer (I) is cured to form the cured resin layer (I ') and then the interface P between the support layer (II) and the cured resin layer (I') is separated by the expansion treatment1) It is usually 2,000mN/25mm or less, preferably 1,000mN/25mm or less, more preferably 500mN/25mm or less, more preferably 150mN/25mm or less, further preferably 100mN/25mm or less, further preferably 50mN/25mm or less, and most preferably 0mN/25 mm.

Peeling force (F)1) The case of 0mN/25mm also includes the case of peeling due to peeling force even when the peeling force is measuredThe force is too small to be measured.

The peel force (F)1) Is a value measured by the following measurement method.

(peeling force (F)1) Measurement of (2)

The support layer (II) side of the laminate was bonded to a glass plate (3mm float glass plate manufactured by U-Kou Co., Ltd. (JIS R3202)). Next, the curable resin layer (I) was cured by heating the glass plate and the laminate at 130 ℃ for 2 hours to form a cured resin layer (I'). In the case where the curable resin layer (I) includes the energy ray-curable resin layer (X2), as in the laminate 4 of fig. 4, the energy ray-curable resin layer (X2) is irradiated with an energy ray (ultraviolet ray) having an illuminance of 215mW/cm after the thermosetting resin layer (X1-1) is thermally cured2Light quantity 187mJ/cm2Irradiation was performed 3 times), and the energy ray-curable resin layer (X2) was cured.

Next, the expandable particles contained in the support layer (II) are expanded. Specifically, when the thermally expandable particles are used, the glass plate to which the laminate is bonded is heated at 240 ℃ for 3 minutes to expand the thermally expandable particles in the expandable base layer (Y1) or the expandable pressure-sensitive adhesive layer (V2) of the laminate. Then, an adhesive tape (product name "PL CHINE" manufactured by Lingdeko K.K.) was attached to the 1 st surface side of the laminate, and the above-mentioned peeling force (F) was applied0) The measurement of (a) was carried out in the same manner as above, and the peel force measured when peeling was carried out at the interface P between the support layer (II) and the cured resin layer (I') under the above conditions was taken as "peel force (F)1)”。

In addition, the peeling force (F)1) In the measurement of (3), when the end of the adhesive tape bonded to the cured resin layer (I ') of the laminate is fixed by the upper chuck of the universal tensile testing machine, the cured resin layer (I') is completely separated at the interface P and the adhesive tape cannot be fixed for measurement, the measurement is terminated, and the peel force (F) at that time is obtained1) The sample was regarded as "0 mN/25 mm".

(Probe tack value of substrate (Y))

The substrate (Y) of the support layer (II) is a non-adhesive substrate.

In one embodiment of the present invention, when determining whether a non-adhesive substrate is used, if the probe tack value measured according to JIS Z0237:1991 with respect to the surface of the target substrate is lower thanThe substrate is judged to be "non-adhesive substrate". On the other hand, the viscosity value of the probe isIn the above, the substrate is judged to be "adhesive substrate".

The support layer (II) used in one embodiment of the present invention has a surface of the substrate (Y) with a probe tack value of generally lower than 50mN/5mm, preferably lower than 30mN/5mm, more preferably lower than 10mN/5mm, and further preferably lower than 5mN/5 mm.

The probe tack value of the surface of the substrate (Y) is a value measured by the following measurement method.

(measurement of Probe tack value)

A substrate to be measured was cut into a square having a side length of 10mm, and the cut substrate was allowed to stand in an atmosphere of 50% RH (relative humidity) at 23 ℃ for 24 hours to obtain a sample as a test sample. The probe tack value on the test sample surface was measured in an environment of 23 ℃ and 50% RH (relative humidity) by using a tack tester (product name "NTS-4800" manufactured by Nippon Special instruments Co., Ltd.) according to JIS Z0237: 1991. Specifically, a probe made of stainless steel having a diameter of 5mm was subjected to a contact load of 0.98N/cm for 1 second2After contacting with the surface of the test sample, the force required to separate the probe from the surface of the test sample at a speed of 10 mm/sec was measured, and the obtained value was taken as the probe tack value of the test sample.

Next, each layer constituting the laminate for preventing warping according to an embodiment of the present invention will be described.

< curable resin layer (I) >

The laminate for preventing warpage according to one embodiment of the present invention has a curable resin layer (I) containing a thermosetting resin layer (X1).

The curable resin layer (I) is cured to reduce the difference in shrinkage stress between the two surfaces of the cured sealing body caused by the curing of the sealing material, and contributes to the suppression of warpage that may occur in the obtained cured sealing body.

The curable resin layer (I) becomes a cured resin layer (I') by curing. The cured resin layer (I') is formed on one surface of the resulting cured encapsulant.

From the viewpoint of suppressing warpage and obtaining a laminate for warpage prevention that can produce a cured sealing body having a flat surface, the storage modulus E 'of the cured resin layer (I') at 23 ℃ is preferably 1.0 × 107Pa or more, more preferably 1.0X 108Pa or more, preferably 1.0X 109Pa or more, more preferably 5.0X 109Pa or more, preferably 1.0X 1013Pa or less, more preferably 1.0X 1012Pa or less, more preferably 5.0X 1011Pa or less, more preferably 1.0X 1011Pa or less.

The storage modulus E 'of the cured resin layer (I') can be measured in the following order.

First, after the curable resin layer (I) was laminated to a thickness of 200 μm, it was cured until the curing was substantially completed (when an exothermic peak at 130 ℃ was lost in a measurement using a differential scanning calorimeter (DSCQ 2000, TA Instruments). In the case of the thermosetting resin layers (X1), (X1-1) and (X1-2), the resin was placed in an oven in an atmospheric atmosphere and heated at 130 ℃ for 2 hours to thermally cure the thermosetting resin layer having a thickness of 200 μm. When the resin layer (X2) and the thermosetting resin layer (X1-1) were included, irradiation with energy rays (ultraviolet rays, illuminance: 215 mW/cm)2Light quantity 187mJ/cm2Irradiation 3 times) to cure the energy ray-curable resin layer (X2), and then the thermosetting resin layer (X1-1) is thermally cured under the above conditions.

Next, the storage modulus E' at 23 ℃ of the formed cured resin layer was measured using a dynamic viscoelasticity measuring apparatus (product name "DMAQ 800" manufactured by TA Instruments) under conditions of a test initiation temperature of 0 ℃, a test completion temperature of 300 ℃, a temperature rise rate of 3 ℃/min, a frequency of 11Hz, and an amplitude of 20 μm.

The surface of the curable resin layer (I) opposite to the support layer, i.e., the 1 st surface, has adhesiveness. The adhesive strength is 1.7N/25mm or more as described above, and is a value measured by bonding the 1 st surface to a glass plate at a temperature of 70 ℃ and peeling the curable resin layer at a temperature of 23 ℃, a peeling angle of 180 ℃ and a peeling speed of 300 mm/min.

In the present specification, the phrase "to be stuck at a temperature of 70 ℃ in the measurement of the adhesive force of the curable resin layer (I)" means that the laminate is stuck to the glass plate by pressing the laminate to the glass plate by a pressing body such as a pressure roller having a heat release temperature of 70 ℃.

The object to be sealed is placed on the 1 st surface of the curable resin layer (I), but the surface of the curable resin layer (I) has the above-described adhesiveness, and therefore, the object to be sealed has good adhesion to the object to be sealed, and it is possible to prevent the object to be sealed from being deviated when the object to be sealed such as a semiconductor chip is placed on the 1 st surface, or the position of the object to be sealed with respect to the curable resin layer (I) from being shifted from an intended position after the object to be sealed is placed.

The shear strength of the curable resin layer (I) with respect to the adherend for measurement is preferably 20N/(3mm × 3mm) or more, which is a value measured at a speed of 200 μm/s by pressing a silicon chip (mirror surface) having a thickness of 350 μm and a size of 3mm × 3mm against the adherend for measurement at a temperature of 70 ℃ for 1 second at 130gf so as to adhere the silicon chip to the curable resin layer.

The adhesive force on the 1 st surface of the curable resin layer (I) and the shear force of the curable resin layer (I) against the adherend for measurement can be adjusted to the above numerical ranges by adjusting the kinds and mixing ratios of the components of the thermosetting resin composition and the energy ray-curable resin composition constituting the curable resin layer (I). The adhesive strength and the shear force vary depending on the components, the blending ratio, etc. of the resin composition, and the shear force also varies depending on the entire layer structure of the curable resin layer (I), but the adhesive strength can be easily increased by using an acrylic polymer described later as a polymer component, an epoxy resin as a thermosetting component, or a coupling agent, for example. In addition, the shear force can be easily increased by increasing the contents of the inorganic filler and the crosslinking agent, for example.

The thickness of the curable resin layer (I) is preferably 1 to 500. mu.m, more preferably 5 to 300. mu.m, still more preferably 10 to 200. mu.m, and still more preferably 15 to 100. mu.m.

(thermosetting resin layer (X1))

The thermosetting resin layers (X1), (X1-1), and (X1-2) are preferably formed from a thermosetting resin composition containing a polymer component (A) and a thermosetting component (B). The thermosetting resin layers (X1), (X1-1) and (X1-2) may be collectively referred to as a thermosetting resin layer (X1).

The curable resin composition may further contain one or more selected from the group consisting of a colorant (C), a coupling agent (D), and an inorganic filler (E). It is preferable that at least the inorganic filler (E) is contained from the viewpoint of suppressing warpage and obtaining a laminate for warpage prevention that can produce a cured sealing body having a flat surface.

The curing initiation temperature of the thermosetting resin layer (X1) is preferably 80 to 200 ℃, more preferably 90 to 160 ℃, and still more preferably 100 to 150 ℃.

When the support layer (II) contains thermally expandable particles, a layer having a curing initiation temperature lower than the expansion initiation temperature of the thermally expandable particles is used as the thermosetting resin layer (X1). The curing start temperature of the thermosetting resin layer (X1) is preferably 5 ℃ or lower, more preferably 10 ℃ or lower, and still more preferably 20 ℃ or lower than the expansion start temperature of the thermally expandable particles.

The thickness of the thermosetting resin layer (X1) may be in the same numerical range as the thickness of the curable resin layer (I).

When the thermosetting resin layer (X1) includes 2 layers as in the case of the thermosetting resin layers (X1-1) and (X1-2), the total thickness thereof may be within the same numerical range as the thickness of the curable resin layer (I). The thickness of the thin layer of these layers is preferably 10% or more, more preferably 20% or more, and still more preferably 30% or more of the thickness of the thick layer.

(Polymer component (A))

The polymer component (a) contained in the thermosetting resin composition is a compound having a weight average molecular weight of 2 ten thousand or more and at least one kind of repeating unit.

By containing the polymer component (a), the thermosetting resin composition can provide flexibility and film formability to the thermosetting resin layer formed and can maintain good properties of the laminate.

The weight average molecular weight (Mw) of the polymer component (a) is preferably 2 ten thousand or more, more preferably 2 to 300 ten thousand, more preferably 5 to 200 ten thousand, further preferably 10 to 150 ten thousand, and further preferably 20 to 100 ten thousand.

The content of the component (a) is preferably 5 to 50% by mass, more preferably 8 to 40% by mass, and still more preferably 10 to 30% by mass, based on the total amount (100% by mass) of the active components in the thermosetting resin composition.

Examples of the polymer component (a) include: acrylic polymers, polyesters, phenoxy resins, polycarbonates, polyethers, polyurethanes, polysiloxanes, rubber polymers, and the like.

These polymer components (a) may be used alone or in combination of two or more.

In the present specification, the acrylic polymer having an epoxy group and the phenoxy resin having an epoxy group are thermosetting, but these resins are considered to be included in the concept of the polymer component (a) as long as they are compounds having a weight average molecular weight of 2 ten thousand or more and at least one kind of repeating unit.

Among these, it is preferable that the polymer component (a) contains the acrylic polymer (a 1).

The content of the acrylic polymer (a1) in the polymer component (a) is preferably 60 to 100 mass%, more preferably 70 to 100 mass%, even more preferably 80 to 100 mass%, and even more preferably 90 to 100 mass% with respect to the total amount (100 mass%) of the polymer component (a) contained in the thermosetting resin composition.

(acrylic Polymer (A1))

From the viewpoint of imparting flexibility and film-forming properties to the thermosetting resin layer formed, the weight average molecular weight (Mw) of the acrylic polymer (a1) is preferably from 2 to 300 million, more preferably from 10 to 150 million, even more preferably from 15 to 120 million, and even more preferably from 25 to 100 million.

The glass transition temperature (Tg) of the acrylic polymer (a1) is preferably-60 to 50 ℃, more preferably-50 to 30 ℃, even more preferably-40 to 10 ℃, and even more preferably-35 to 5 ℃ from the viewpoint of imparting good adhesion to the surface of the thermosetting resin layer formed and improving the reliability of the cured sealing body with a cured resin layer produced using the laminate for warpage prevention.

The acrylic polymer (a1) includes a polymer containing an alkyl (meth) acrylate as a main component, and specifically, is preferably an acrylic polymer containing a structural unit (a1) derived from an alkyl (meth) acrylate (a1 ') having an alkyl group having 1 to 18 carbon atoms (hereinafter, also referred to as "monomer (a 1')"), and is more preferably an acrylic copolymer containing a structural unit (a1) and a structural unit (a2) derived from a functional group-containing monomer (a2 ') (hereinafter, also referred to as "monomer (a 2')").

The acrylic polymer (a1) may be used alone or in combination of two or more.

When the acrylic polymer (a1) is a copolymer, the form of the copolymer may be any of a block copolymer, a random copolymer, an alternating copolymer, and a graft copolymer.

From the viewpoint of imparting flexibility and film-forming properties to the thermosetting resin layer formed, the alkyl group of the monomer (a 1') preferably has 1 to 18 carbon atoms, more preferably 1 to 12 carbon atoms, and still more preferably 1 to 8 carbon atoms. The alkyl group may be a straight chain alkyl group or a branched chain alkyl group.

These monomers (a 1') may be used alone or in combination of two or more.

From the viewpoint of improving the reliability of a cured sealing body with a cured resin layer produced using the warpage-preventing laminate, the monomer (a 1') preferably contains an alkyl (meth) acrylate having an alkyl group with 1 to 3 carbon atoms, and more preferably contains methyl (meth) acrylate.

From the above viewpoint, the content of the structural unit (a11) derived from an alkyl (meth) acrylate having an alkyl group with 1 to 3 carbon atoms is preferably 1 to 80% by mass, more preferably 5 to 80% by mass, and still more preferably 10 to 80% by mass, based on the total structural units (100% by mass) of the acrylic polymer (a 1).

The monomer (a 1') preferably contains an alkyl (meth) acrylate having an alkyl group having 4 or more carbon atoms, more preferably contains an alkyl (meth) acrylate having an alkyl group having 4 to 6 carbon atoms, and still more preferably contains butyl (meth) acrylate.

From the above viewpoint, the content of the structural unit (a12) derived from an alkyl (meth) acrylate having an alkyl group having 4 or more carbon atoms (preferably 4 to 6, more preferably 4) is preferably 1 to 70% by mass, more preferably 5 to 65% by mass, and even more preferably 10 to 60% by mass, based on the total structural units (100% by mass) of the acrylic polymer (a 1).

The content of the structural unit (a1) is preferably 50% by mass or more, more preferably 50 to 99% by mass, even more preferably 55 to 90% by mass, and even more preferably 60 to 90% by mass, based on the total structural units (100% by mass) of the acrylic polymer (a 1).

The monomer (a 2') is preferably at least one monomer selected from the group consisting of hydroxyl group-containing monomers and epoxy group-containing monomers.

The monomer (a 2') may be used alone or in combination of two or more.

Examples of the hydroxyl group-containing monomer include: hydroxyalkyl (meth) acrylates such as 2-hydroxyethyl (meth) acrylate, 2-hydroxypropyl (meth) acrylate, 3-hydroxypropyl (meth) acrylate, 2-hydroxybutyl (meth) acrylate, 3-hydroxybutyl (meth) acrylate, and 4-hydroxybutyl (meth) acrylate; unsaturated alcohols such as vinyl alcohol and allyl alcohol.

Among these, the hydroxyl group-containing monomer is preferably a hydroxyalkyl (meth) acrylate, and more preferably 2-hydroxyethyl (meth) acrylate.

Examples of the epoxy group-containing monomer include: epoxy group-containing (meth) acrylates such as glycidyl (meth) acrylate, β -methylglycidyl (meth) acrylate, (3, 4-epoxycyclohexyl) methyl (meth) acrylate, and 3-epoxycyclo-2-hydroxypropyl (meth) acrylate; glycidyl crotonate, allyl glycidyl ether, and the like.

Among these, the epoxy group-containing monomer is preferably an epoxy group-containing (meth) acrylate, and more preferably glycidyl (meth) acrylate.

The content of the structural unit (a2) is preferably 1 to 50 mass%, more preferably 5 to 45 mass%, even more preferably 10 to 40 mass%, and even more preferably 10 to 30 mass% with respect to the total structural units (100 mass%) of the acrylic polymer (a 1).

The acrylic polymer (a1) may have a structural unit derived from another monomer other than the structural units (a1) and (a2) as long as the effects of the present invention are not impaired.

Examples of the other monomers include: vinyl acetate, styrene, ethylene, alpha-olefins, and the like.

(thermosetting component (B))

The thermosetting component (B) functions to form a hard cured resin layer by thermosetting the formed thermosetting resin layer, and is a compound having a weight average molecular weight of less than 2 ten thousand.

The weight average molecular weight (Mw) of the thermosetting component (B) is preferably 10,000 or less, more preferably 100 to 10,000.

From the viewpoint of obtaining a laminate for preventing warpage, which is capable of suppressing warpage and producing a cured sealing body having a flat surface, the thermosetting component (B) preferably contains an epoxy compound (B1) which is a compound having an epoxy group and a thermosetting agent (B2), and more preferably contains an epoxy compound (B1) and a thermosetting agent (B2) and further contains a curing accelerator (B3).

Examples of the epoxy compound (B1) include: polyfunctional epoxy resins, bisphenol a diglycidyl ethers and hydrogenated products thereof, o-cresol novolac epoxy resins, dicyclopentadiene epoxy resins, biphenyl epoxy resins, bisphenol a epoxy resins, bisphenol F epoxy resins, phenylene skeleton epoxy resins, and the like, and epoxy compounds having 2 or more functions in the molecule and a weight average molecular weight of less than 2 ten thousand.

The epoxy compounds (B1) may be used alone or in combination of two or more.

From the viewpoint of obtaining a laminate for warpage prevention that can suppress warpage and can produce a cured sealing body having a flat surface, the content of the epoxy compound (B1) is preferably 1 to 500 parts by mass, more preferably 3 to 300 parts by mass, even more preferably 10 to 150 parts by mass, and even more preferably 20 to 120 parts by mass, relative to 100 parts by mass of the polymer component (a) contained in the thermosetting resin composition.

The heat-curing agent (B2) functions as a curing agent for the epoxy compound (B1).

The thermosetting agent is preferably a compound having 2 or more functional groups capable of reacting with an epoxy group in 1 molecule.

Examples of the functional group include a phenolic hydroxyl group, an alcoholic hydroxyl group, an amino group, a carboxyl group, and an acid anhydride. Among these, from the viewpoint of obtaining an adhesive laminate capable of producing a cured sealant with a cured resin layer having a flat surface while suppressing warpage, a phenolic hydroxyl group, an amino group, or an acid anhydride is preferable, a phenolic hydroxyl group or an amino group is more preferable, and an amino group is even more preferable.

Examples of the phenolic thermosetting agent having a phenolic hydroxyl group include: polyfunctional phenol resins, biphenols, novolak-type phenol resins, dicyclopentadiene-type phenol resins, XYLOK-type phenol resins, aralkyl-type phenol resins, and the like.

Examples of the amine-based heat curing agent having an amino group include dicyandiamide.

These heat-curing agents (B2) may be used alone or in combination of two or more.

The content of the thermosetting agent (B2) is preferably 0.1 to 500 parts by mass, more preferably 1 to 200 parts by mass, per 100 parts by mass of the epoxy compound (B1), from the viewpoint of obtaining an adhesive laminate capable of producing a cured sealant having a flat surface and a cured resin layer.

The curing accelerator (B3) is a compound having a function of increasing the thermosetting speed when the thermosetting resin layer formed is thermally cured.

Examples of the curing accelerator (B3) include: tertiary amines such as triethylenediamine, benzyldimethylamine, triethanolamine, dimethylaminoethanol, and tris (dimethylaminomethyl) phenol; imidazoles such as 2-methylimidazole, 2-phenylimidazole, 2-phenyl-4-methylimidazole, 2-phenyl-4, 5-dihydroxymethylimidazole and 2-phenyl-4-methyl-5-hydroxymethylimidazole; organic phosphines such as tributylphosphine, diphenylphosphine, and triphenylphosphine; tetraphenylboron salts such as tetraphenylphosphonium tetraphenylborate and triphenylphosphine tetraphenylborate.

These curing accelerators (B3) may be used alone or in combination of two or more.

From the viewpoint of obtaining a laminate for warpage prevention that can suppress warpage and produce a cured sealing body having a flat surface, the content of the curing accelerator (B3) is preferably 0.01 to 10 parts by mass, more preferably 0.1 to 6 parts by mass, and even more preferably 0.3 to 4 parts by mass, relative to 100 parts by mass of the total amount of the epoxy compound (B1) and the thermosetting agent (B2).

(colorant (C))

The thermosetting resin composition used in one embodiment of the present invention may further contain a colorant (C).