CN111535484B - Integral spraying wall structure with inner and outer moulds - Google Patents

Integral spraying wall structure with inner and outer moulds Download PDFInfo

- Publication number

- CN111535484B CN111535484B CN202010376905.4A CN202010376905A CN111535484B CN 111535484 B CN111535484 B CN 111535484B CN 202010376905 A CN202010376905 A CN 202010376905A CN 111535484 B CN111535484 B CN 111535484B

- Authority

- CN

- China

- Prior art keywords

- mold

- light steel

- molds

- steel keel

- wall

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B2/00—Walls, e.g. partitions, for buildings; Wall construction with regard to insulation; Connections specially adapted to walls

- E04B2/84—Walls made by casting, pouring, or tamping in situ

- E04B2/86—Walls made by casting, pouring, or tamping in situ made in permanent forms

- E04B2/8658—Walls made by casting, pouring, or tamping in situ made in permanent forms using wire netting, a lattice or the like as form leaves

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A30/00—Adapting or protecting infrastructure or their operation

- Y02A30/24—Structural elements or technologies for improving thermal insulation

- Y02A30/244—Structural elements or technologies for improving thermal insulation using natural or recycled building materials, e.g. straw, wool, clay or used tires

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Forms Removed On Construction Sites Or Auxiliary Members Thereof (AREA)

- Rod-Shaped Construction Members (AREA)

Abstract

The invention provides an integral spraying and building wall body structure with an inner mold and an outer mold, which comprises a steel mesh and a leaf wall, wherein the steel mesh is used as the parallel inner mold and/or outer mold, the two inner molds are arranged inside the two outer molds respectively and are positioned at the two sides of the inner molds, a light steel keel framework connected with the inner molds is arranged between the inner molds, and the two ends of the light steel keel framework are assembled and connected with a structural column/beam through connecting pieces; and a partition is arranged between the inner mold and the outer mold and fixedly connected with the inner mold and the outer mold, the outer mold is provided with meshes, leaf wall materials are sprayed on the outer mold to form leaf walls, and the leaf wall materials penetrate through the meshes of the outer mold to connect and wrap the inner mold. The wall framework provided by the invention has high strength, the leaf wall material and the wall framework are good in embedding property, the wall and the structural column/beam form flexible connection and a special expansion joint, the wall material is controlled in the expansion joint under the stress of temperature difference change, and the defect of wall cracking is effectively overcome.

Description

Technical Field

The invention relates to an integral spraying and building steel mesh wall of a building, in particular to an integral spraying and building wall body structure with an inner mold and an outer mold.

Background

In order to protect cultivated land, reduce emission and protect environment, the nation seriously advocates and popularizes and uses various novel wall bodies and wall materials which are energy-saving, emission-reducing, waste-utilizing, green and environment-friendly and forbid the production and use of clay bricks. The state prohibits adhesion, reduce the all kinds of novel light weight wallboards that use after controlling all kinds of brickworks, there is the bottleneck that the temperature difference change leads to wallboard deformation to stretch the board seam and be difficult to overcome after the installation, the whole of using spouts builds the cavity, steel mesh centre form wall body, there is the whole that can only use fine paste to spout, it hangs on steel mesh centre form net to glue, but the sand granule is thin easily cracked, the sand granule has been thick the spouting can lead to the rebound of thick liquid material granule, it can not go up wall centre form steel mesh to glue, drop, wall layer arrangement of reinforcement is weak, in addition wall body and post, beam structure connect for factors such as rigid connection, there is the wall material shrink that wall hydraulicity brittle hardening material receives the temperature difference change to lead to, wall body fracture defect such as serious.

Disclosure of Invention

Aiming at the defects of the prior art, the invention provides an integral spraying and building wall body structure with an inner mold and an outer mold, which is convenient to install, not easy to deform and crack, and long in service life.

In order to achieve the above purpose, the technical scheme provided by the invention is as follows: a kind of whole spray building wall body structure with inner and outer mould, including steel mesh and leaf wall, the said steel mesh is regarded as parallel internal mold and/or external mold, two internal molds are included, two external molds locate at both sides of the internal mold separately, there is light steel keel skeleton connected with internal mold between the internal molds, both ends of the light steel keel skeleton are assembled with structural column/roof beam through the connecting piece; and a partition is arranged between the inner mold and the outer mold and fixedly connected with the inner mold and the outer mold, the outer mold is provided with meshes, leaf wall materials are sprayed on the outer mold to form leaf walls, and the leaf wall materials penetrate through the meshes of the outer mold to connect and wrap the inner mold.

According to the technical scheme, the inner mold and the outer mold are arranged, the light steel keel framework connected with the inner mold is arranged in the inner mold, the light steel keel framework is used as a vertical or horizontal wall supporting structure of a wall, the distance between the light steel keel frameworks is different according to the requirement of seismic intensity, the vertical face width of the light steel keel framework is the hollow distance between the double-layer inner molds or the thickness of the light filling plate, and different specifications are selected according to the required application. The light steel keel framework, the inner framework, the partition pieces and the outer framework are connected into a whole, so that the overall strength of the wall body is ensured, the strength of the wall body is higher, the higher strength and the higher rigidity can be achieved even if the thickness of the leaf wall is thinner, the wall body is not easy to deform and crack, and the integrated reinforced wall body framework is formed, so that the wall body is good in integrity and high in strength; in order to improve the crack resistance, the two ends of the concave light steel keel are assembled and connected with the structural column/beam through the connecting pieces, the assembly mode does not need electric welding on the installation site, the installation is simple and convenient, more importantly, the wall body and the structural column/beam form flexible connection instead of direct welding rigid connection, the wall body material is stressed by temperature difference change, can be controlled in the expansion joint, and the crack defect of the wall body is effectively overcome; the inner mold and the outer mold, i.e. the externally hung steel mesh, form a separation connecting net rack by the separating pieces, and the concrete and cement paste leaf wall materials are poured in to form a wall concrete protective layer between the inner mold and the outer mold.

Furthermore, in order to obtain better structural strength and facilitate connection, the light steel keel framework is a concave light steel keel which is arranged in parallel, two side faces of the concave light steel keel are respectively attached to the internal mold, and the partition, the internal mold and the two side faces of the concave light steel keel are connected through self-tapping screws.

Furthermore, the connecting piece is a T-shaped connecting piece, the T-shaped connecting piece comprises a head part and a tail part which are connected, the tail part is vertically connected to the middle position of the head part, and a strip-shaped hole which is formed along the length direction of the tail part is formed in the tail part. The head of the T-shaped connecting piece is attached to the structural column/beam, the tail of the T-shaped connecting piece is attached to the concave light steel keel, and the strip-shaped holes enable the screws to slide along the strip-shaped holes when the wall shrinks, so that the wall and the column/beam are connected flexibly.

Furthermore, the tail part of the T-shaped connecting piece is inserted into the concave light steel keel, and the tapping screw penetrates through the strip-shaped hole to be connected with the concave light steel keel; the head of the T-shaped connector is connected to the structural column/beam by a self-tapping screw or a nail.

Furthermore, in order to form better supporting strength, heat preservation and flame retardance, the light steel keel frameworks are vertically arranged, and light flame-retardant heat preservation plate cores or rock wool and glass wool are arranged in the hollow space between the internal molds.

Further, the light flame-retardant insulation board core is a flame-retardant polystyrene board or a flame-retardant extruded board.

Furthermore, the inner mold is a dense-mesh steel mesh or a light plate, and the outer mold is a medium-mesh steel mesh, a steel plate stretching mesh or a steel bar welding mesh.

Furthermore, the separating pieces are a plurality of concave light steel keels with holes on two side surfaces, the concave light steel keels with the holes are perpendicular to the light steel keel framework, the bottom surfaces of the concave light steel keels with the holes are connected with the inner die in an attached mode, and two ends of the separating pieces are connected with the structural columns/beams through the T-shaped connecting pieces. The side surface of the concave light steel keel is provided with a hole, so that the leaf wall material can enter the inner mold more easily and smoothly, and the embedding degree of the leaf wall material and the net rack formed by the separating piece is higher; two ends of the separator are connected with the structural column/beam through the T-shaped connecting piece to form an assembled flexible connection, so that the defect of cracking of the wall body is further overcome.

Further, as an embodiment which saves materials and is more beneficial to filling of the leaf wall materials, the separating parts are a plurality of distributed concave cushion blocks, the bottom surfaces of the concave cushion blocks are connected with the inner die in a leaning and leaning manner, and holes are formed in two side surfaces of each concave cushion block.

Furthermore, the leaf wall material is solid waste recycled concrete, construction waste recycled concrete or stone yard waste stone powder concrete, and the recycled material is adopted, so that the environment is protected and the waste is utilized.

In conclusion, the beneficial effects of the invention are as follows:

1. the leaf wall has the advantages that the integral wall body framework is formed by the light steel keel, the inner die, the partition and the outer die, leaf wall materials can be easily sprayed between the inner die and the outer die, the tabling performance of the leaf wall materials and the wall body framework is good, the wall body is good in integrity, high in strength and good in rigidity, and the leaf wall materials are not prone to cracking.

2. The wall body is assembled and connected with the structural column/beam through the T-shaped connecting piece with the strip-shaped hole, electric welding is not needed during installation, the installation is simple and convenient, more importantly, the wall body and the structural column/beam form flexible connection instead of direct welded rigid connection, and the wall body material can be controlled in an expansion joint under the stress of temperature difference change, so that the cracking defect of the wall body is effectively overcome.

Drawings

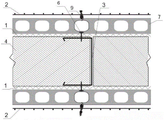

Fig. 1 is a schematic structural diagram of embodiment 1 of the present invention.

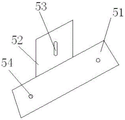

Fig. 2 is a schematic structural view of the T-shaped connector in embodiment 1.

Fig. 3 is a schematic view of the connection structure of the tail part of the T-shaped connector and the framework of the light steel keel in example 1 (the tapping screw is not shown).

Fig. 4 is a schematic view of the connection structure of the T-shaped connector and the separator in example 1 (tapping screw not shown).

Fig. 5 is a schematic structural diagram of embodiment 2 of the present invention.

Fig. 6 is a schematic view of the separator of fig. 5.

Detailed Description

Example 1:

as shown in fig. 1, an integral spraying wall body structure with an inner mold and an outer mold comprises a steel mesh and a leaf wall, wherein the steel mesh is used as an inner mold 1 and/or an outer mold 2 which are parallel, the two inner molds 1 are arranged inside the two inner molds 1, the two outer molds 2 are respectively arranged at two sides of the inner molds 1, a light steel keel framework 3 connected with the inner molds 1 is arranged between the inner molds 1, and two ends of the light steel keel framework 3 are assembled and connected with a structural beam through connecting pieces; the inner mold 1 and the outer mold 2 are provided with a partition and fixedly connected with each other, the outer mold 2 is provided with meshes, leaf wall materials are sprayed on the outer mold 2 to form leaf walls, the leaf wall materials penetrate through the meshes of the outer mold 2 to connect and coat the inner mold 1, the inner mold 1 is a dense-mesh steel mesh, the outer mold 2 is a medium-mesh steel mesh, and the leaf wall materials are solid waste recycled concrete or construction waste recycled concrete.

In order to obtain better structural strength and facilitate connection, the light steel keel frameworks 3 are concave light steel keels which are arranged in parallel, in the embodiment, the light steel keel frameworks 3 are vertically arranged, light flame-retardant insulation board cores 4 are placed between the internal molds 1, the light flame-retardant insulation board cores 4 are made of flame-retardant polyphenyl boards or flame-retardant extruded boards, rock wool or glass wool can be used, and the internal molds 1 can be hollow. The bottom surface of the concave light steel keel is provided with a reinforcing rib, two side surfaces of the concave light steel keel are respectively attached to the two internal molds 1 at two sides, and the partition, the internal molds 1 and the two side surfaces of the concave light steel keel are connected through self-tapping screws 6.

As shown in fig. 1 to 3, the connecting member is a T-shaped connecting member 5, and in order to improve crack resistance, both ends of the vertical concave light steel keel are assembled and connected with the structural beam through the T-shaped connecting member 5, so that the wall body and the structural beam can form flexible connection, rather than rigid connection by direct welding. The T-shaped connecting piece 5 comprises a head part 51 and a tail part 52 which are connected, the head part 51 and the tail part 52 are sheet-shaped, the tail part 52 is vertically connected to the middle position of the head part 51, mounting holes 54 for self-tapping screws are arranged on two sides of the head part 51, and strip-shaped holes 53 which are formed along the length direction of the tail part 52 are arranged on the tail part 52. The head 51 of the T-shaped connecting piece 5 is attached to the structural beam and is connected with the structural beam through a self-tapping screw or a shooting nail; the tail 52 of the T-shaped connecting piece 5 is inserted into the concave light steel keel serving as the light steel keel framework 3, the tail 52 is attached to the side face of the concave light steel keel, the tapping screw penetrates through the strip-shaped hole 53 to be connected with the concave light steel keel, and the strip-shaped hole 53 enables the screw to slide along the strip-shaped hole 53 when the wall shrinks, so that the wall and the column/beam are connected in a better flexible mode.

As shown in fig. 1, fig. 2 and fig. 4, the partitioning members in this embodiment are a plurality of concave light gauge steel 7 having holes on both sides, the concave light gauge steel 7 having holes is horizontally arranged to be perpendicular to the light gauge steel framework 3, and the bottom surface thereof is connected to the inner formwork 1 in an abutting manner; the side surface of the concave light steel keel 7 is provided with a hole, so that the leaf wall material can enter the inner mold 1 more easily and smoothly, and the tabling degree of the leaf wall material and the net rack formed by the separator is higher. The hole can also be conveniently tied up the mode through the iron wire and be connected separator and external mold 2, and the both ends of separator are then connected with the structure post through T-shaped connecting piece 5, and the afterbody 52 of T-shaped connecting piece 5 pastes mutually with the bottom surface of separator and leans on and is connected through self-tapping screw, and the both ends of separator are connected with the structure post through T-shaped connecting piece 5 and are formed assembled flexible connection, further overcome wall body fracture defect.

Example 2: the components, the structures of the components and the mutual relations among the components included in the embodiment are basically the same as those in embodiment 1, except that as shown in fig. 5 and 6, the separating elements are a plurality of distributed concave cushion blocks 8, the bottom surfaces of the concave cushion blocks 8 are connected with the inner die 1 in a leaning and leaning manner, holes 81 are formed in two side surfaces of each concave cushion block 8, semicircular notches 82 are formed in one outer edge of each side surface of each concave cushion block 8, iron wires 9 can conveniently penetrate through the concave cushion blocks 8 to be connected with the outer die 2 in a binding manner, and the concave cushion blocks 8 are used as the separating elements, so that the embodiment is more material-saving and more favorable for filling of leaf wall materials. In the embodiment, the inner molds 1 are light plates, the space between the two inner molds 1 is hollow, the outer molds 2 are steel plate stretching nets or steel bar welding nets, and the leaf wall material adopts construction waste recycled concrete or stone yard waste stone powder concrete.

Although the present invention has been described in detail with reference to the preferred embodiments, it will be understood by those skilled in the art that various changes may be made and equivalents may be substituted without departing from the spirit and scope of the invention as defined in the appended claims.

Claims (6)

1. The utility model provides an integral spraying wall body structure with interior outer mould, includes steel mesh and leaf wall, its characterized in that: the steel mesh is used as a parallel inner mold and/or outer mold, the two inner molds are arranged inside the steel mesh, the two outer molds are respectively positioned at two sides of the inner molds, a light steel keel framework connected with the inner molds is arranged between the inner molds, and two ends of the light steel keel framework are assembled and connected with the structural column/beam through connecting pieces; a partition is arranged between the inner mold and the outer mold and fixedly connected with the inner mold and the outer mold, the outer mold is provided with meshes, leaf wall materials are sprayed on the outer mold to form leaf walls, and the leaf wall materials penetrate through the meshes of the outer mold to connect and wrap the inner mold;

the light steel keel framework is concave light steel keels which are arranged in parallel, two side surfaces of each concave light steel keel are respectively attached to the inner die, and the partition, the inner die and the two side surfaces of each concave light steel keel are connected through self-tapping screws; the connecting piece is a T-shaped connecting piece, the T-shaped connecting piece comprises a head part and a tail part which are connected, the tail part is vertically connected to the middle position of the head part, and a strip-shaped hole which is formed along the length direction of the tail part is formed in the tail part; the light steel keel frameworks are vertically arranged, and a light flame-retardant insulation board core or rock wool or glass wool is arranged in a hollow manner between the internal molds; the partition is a plurality of concave light steel keels with holes on two side surfaces, the concave light steel keels with the holes are perpendicular to the light steel keel framework, the bottom surfaces of the concave light steel keels with the holes are connected with the internal mold in a leaning and attaching mode, and two ends of the partition are connected with the structural column/beam through the T-shaped connecting piece.

2. The integral spray wall construction with inner and outer forms of claim 1, wherein: the tail part of the T-shaped connecting piece is inserted into the concave light steel keel, and the tapping screw penetrates through the strip-shaped hole to be connected with the concave light steel keel; the head of the T-shaped connector is connected to the structural column/beam by a self-tapping screw or a nail.

3. The integral spray wall construction with inner and outer forms of claim 1, wherein: the light flame-retardant insulation board core is a flame-retardant polystyrene board or a flame-retardant extruded board.

4. The integral spray wall construction with inner and outer forms of claim 1, wherein: the inner mold is a dense-mesh steel mesh or a light plate, and the outer mold is a medium-mesh steel mesh, a steel plate stretching mesh or a steel bar welding mesh.

5. The utility model provides an integral spraying wall body structure with interior outer mould, includes steel mesh and leaf wall, its characterized in that: the steel mesh is used as parallel outer molds, the two inner molds are light plates, the two outer molds are respectively positioned on two sides of the inner molds, a light steel keel framework connected with the inner molds is arranged between the inner molds, and two ends of the light steel keel framework are assembled and connected with the structural column/beam through connecting pieces; a partition is arranged between the inner mold and the outer mold and fixedly connected with the inner mold and the outer mold, the outer mold is provided with meshes, leaf wall materials are sprayed on the outer mold to form leaf walls, and the leaf wall materials penetrate through the meshes of the outer mold to connect and wrap the inner mold;

the light steel keel framework is a concave light steel keel which is arranged in parallel, two side surfaces of the concave light steel keel are respectively attached to the inner die, and the partition, the inner die and the two side surfaces of the concave light steel keel are connected through self-tapping screws; the connecting piece is a T-shaped connecting piece, the T-shaped connecting piece comprises a head part and a tail part which are connected, the tail part is vertically connected to the middle position of the head part, and a strip-shaped hole which is formed along the length direction of the tail part is formed in the tail part; the light steel keel frameworks are vertically arranged, and the internal molds are hollow; the separator is a plurality of concave cushion blocks that distribute, and the bottom surface of concave cushion block is connected with the centre form is leaned on mutually, and the both sides face of concave cushion block is equipped with the hole.

6. The construction of an integral spray wall having inner and outer forms according to any one of claims 1 to 5, wherein: the leaf wall material is solid waste recycled concrete, construction waste recycled concrete or stone yard waste stone powder concrete.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010376905.4A CN111535484B (en) | 2020-05-07 | 2020-05-07 | Integral spraying wall structure with inner and outer moulds |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010376905.4A CN111535484B (en) | 2020-05-07 | 2020-05-07 | Integral spraying wall structure with inner and outer moulds |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111535484A CN111535484A (en) | 2020-08-14 |

| CN111535484B true CN111535484B (en) | 2022-09-06 |

Family

ID=71978990

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010376905.4A Active CN111535484B (en) | 2020-05-07 | 2020-05-07 | Integral spraying wall structure with inner and outer moulds |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111535484B (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112922193B (en) * | 2021-01-26 | 2023-02-03 | 昆明吉奥金属容器制造有限公司 | Composite partition wall with steel mesh outer mold structure of light steel combined frame and manufacturing method thereof |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0266246A (en) * | 1988-08-31 | 1990-03-06 | Toyo Bussan Kk | Insulating concrete with space truss and construction thereof |

| IT233319Y1 (en) * | 1993-02-26 | 2000-01-28 | Ntc Srl | PREFABRICATED STRUCTURAL PANEL. |

| FI952149A (en) * | 1995-05-04 | 1996-11-05 | Ma Rakennus J Maentylae Ky | Wall construction and method of making wall construction |

| CN103061432B (en) * | 2010-04-21 | 2015-08-12 | 成都绿建科技有限公司 | The construction method of light energy-saving thermal insulation non-bearing wall body |

| CN204112532U (en) * | 2014-02-12 | 2015-01-21 | 杜洪宇 | Integral light grouting heat-preserving wall |

| CN107435401A (en) * | 2017-09-12 | 2017-12-05 | 徐焱 | A kind of structure outer filled with modified polyphenyl particle concrete |

| CN207959614U (en) * | 2017-12-29 | 2018-10-12 | 天元建设集团有限公司 | A kind of heat preservation decoration integrative embedded wall harden structure |

| CN209637039U (en) * | 2019-01-02 | 2019-11-15 | 常州市米尼特机械有限公司 | A kind of cast-in-place foamed concrete wall steel mesh connection card |

| CN109779102A (en) * | 2019-03-04 | 2019-05-21 | 中国五冶集团有限公司 | Lattice keel expanded metal lath mould composite wall and its construction method |

| CN109779087A (en) * | 2019-03-22 | 2019-05-21 | 湖南迈豪斯建筑科技有限公司 | A kind of light gauge steel structure and wall |

| CN110541518A (en) * | 2019-10-08 | 2019-12-06 | 唐元元 | Non-bearing steel bar net and thin steel plate sandwich composite wall and manufacturing method thereof |

| CN110761455A (en) * | 2019-10-21 | 2020-02-07 | 刘德政 | Fireproof, damping and heat-preservation steel mesh and internal mold integrated wall and construction process thereof |

-

2020

- 2020-05-07 CN CN202010376905.4A patent/CN111535484B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN111535484A (en) | 2020-08-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110409811B (en) | Non-dismantling forming column template containing reinforcement cage, template structure and building process | |

| CN110409813B (en) | Non-dismantling forming beam template containing reinforcement cage, template structure and building process | |

| CN209817249U (en) | A compound wallboard of prefabricated foam concrete for building infilled wall | |

| WO2017219451A1 (en) | Beam and column integrated wallboard | |

| CN115354793A (en) | Prefabricated ceramsite and foam concrete composite shear wall provided with triangular-cone truss ribs and preparation method of prefabricated ceramsite and foam concrete composite shear wall | |

| CN113898093A (en) | Assembled light steel-foam concrete load-bearing composite wall and construction method thereof | |

| CN111535484B (en) | Integral spraying wall structure with inner and outer moulds | |

| CN107119826B (en) | Autoclaved aerated concrete plate filling wall and column connecting node structure and construction method thereof | |

| CN106677362B (en) | Opening box type heat-insulation wallboard structure with built-in connecting bolt and construction method thereof | |

| CN216276295U (en) | Assembled lightweight steel-foam concrete load-bearing composite wall | |

| CN205954910U (en) | Beam column integration wallboard | |

| CN112922193B (en) | Composite partition wall with steel mesh outer mold structure of light steel combined frame and manufacturing method thereof | |

| CN218522008U (en) | Evaporate and press light aerated concrete slab outer wall structure | |

| CN110714573B (en) | HJ assembled multifunctional wall board | |

| CN201050192Y (en) | Expansion-proof assembly for building cast-in-situ lightweight composite wall | |

| CN210105043U (en) | Ultralow energy consumption steel construction heat preservation integration wall structure | |

| CN212053307U (en) | Steel wire net frame cement light composite heat insulation wall | |

| CN210049426U (en) | Building thermal insulation wall | |

| CN210827940U (en) | Building structure based on steel construction coincide wall | |

| CN109505422B (en) | Reinforcing method for ancient building wall | |

| CN114274306A (en) | Production process of prefabricated steel structure exterior wall cladding | |

| CN102182262A (en) | Armored foamed concrete thermal insulation wall | |

| CN201198612Y (en) | Light energy-saving large module combined type external wall body | |

| CN102287013B (en) | Composite hole inorganic concrete phenolic heat insulation fireproof wallboard | |

| CN111021544A (en) | Large-span variable-space assembly type building and construction method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| TA01 | Transfer of patent application right |

Effective date of registration: 20220725 Address after: 650000 a-1-101, building 7, hengchen Industrial Park, Tianshui Road, Yanglin Development Zone, Songming County, Kunming City, Yunnan Province Applicant after: KUNMING JI'AO METAL CONTAINER MANUFACTURING Co.,Ltd. Address before: 650231 Room 1702, Unit B, C2 Building, Chunzhi District, Liyulu Road, Wuhua District, Kunming City, Yunnan Province Applicant before: Tang Fangfang |

|

| TA01 | Transfer of patent application right | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |