CN111391145A - Toughened glass perforating device - Google Patents

Toughened glass perforating device Download PDFInfo

- Publication number

- CN111391145A CN111391145A CN202010290708.0A CN202010290708A CN111391145A CN 111391145 A CN111391145 A CN 111391145A CN 202010290708 A CN202010290708 A CN 202010290708A CN 111391145 A CN111391145 A CN 111391145A

- Authority

- CN

- China

- Prior art keywords

- workbench

- oil

- positioning

- plate

- tempered glass

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000005341 toughened glass Substances 0.000 title claims abstract description 35

- 230000005540 biological transmission Effects 0.000 claims abstract description 14

- 238000004080 punching Methods 0.000 claims abstract description 14

- 230000007246 mechanism Effects 0.000 claims description 23

- 230000001050 lubricating effect Effects 0.000 claims description 12

- 239000011521 glass Substances 0.000 claims description 6

- 238000005461 lubrication Methods 0.000 claims description 3

- 238000004519 manufacturing process Methods 0.000 claims description 2

- 238000005496 tempering Methods 0.000 claims 1

- 239000003921 oil Substances 0.000 description 41

- 239000010687 lubricating oil Substances 0.000 description 6

- 230000033001 locomotion Effects 0.000 description 3

- 238000000034 method Methods 0.000 description 3

- 230000008569 process Effects 0.000 description 3

- 238000005553 drilling Methods 0.000 description 2

- 230000004075 alteration Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 125000004122 cyclic group Chemical group 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000011152 fibreglass Substances 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000000053 physical method Methods 0.000 description 1

- 239000005336 safety glass Substances 0.000 description 1

- 239000007921 spray Substances 0.000 description 1

- 239000000126 substance Substances 0.000 description 1

- 238000006467 substitution reaction Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28D—WORKING STONE OR STONE-LIKE MATERIALS

- B28D1/00—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor

- B28D1/14—Working stone or stone-like materials, e.g. brick, concrete or glass, not provided for elsewhere; Machines, devices, tools therefor by boring or drilling

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28D—WORKING STONE OR STONE-LIKE MATERIALS

- B28D7/00—Accessories specially adapted for use with machines or devices of the preceding groups

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B28—WORKING CEMENT, CLAY, OR STONE

- B28D—WORKING STONE OR STONE-LIKE MATERIALS

- B28D7/00—Accessories specially adapted for use with machines or devices of the preceding groups

- B28D7/04—Accessories specially adapted for use with machines or devices of the preceding groups for supporting or holding work or conveying or discharging work

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Mining & Mineral Resources (AREA)

- Re-Forming, After-Treatment, Cutting And Transporting Of Glass Products (AREA)

Abstract

The invention relates to a tempered glass punching device, which comprises a workbench, a support leg and a drill bit, wherein a groove body for placing a tempered glass body is arranged on the workbench, the support leg is arranged at the bottom of the workbench, the drill bit is fixedly connected with the output end of a lifting cylinder through a telescopic rod, the device also comprises a second mounting frame, a second slide block, a first mounting frame and a first slide block, the second mounting frame is arranged at the side end of the workbench, the second slide block is connected on the second mounting frame in a sliding manner, the second slide block is connected with the output end of a second motor in a transmission manner through a second stepping driving assembly, the first mounting frame is arranged on one side surface of the second slide block close to the workbench, the first slide block is connected on the first mounting frame in a sliding manner, the first slide block is connected with the output end of the first motor in a transmission manner through the first stepping driving assembly, and the lifting cylinder is arranged at the bottom of the first slide, the punching position is adjusted, and the efficiency is improved.

Description

Technical Field

The invention relates to the field of toughened glass processing equipment, in particular to a toughened glass punching device.

Background

The toughened glass belongs to safety glass. The tempered glass is actually prestressed glass, and in order to improve the strength of the glass, a chemical or physical method is usually used to form compressive stress on the surface of the glass, and the glass firstly counteracts surface stress when bearing external force, so that the bearing capacity is improved, and the wind pressure resistance, the cold and hot property, the impact property and the like of the glass are enhanced. Note the distinction from glass reinforced plastic.

Among the prior art toughened glass production process, punch and be very important flow step, but traditional toughened glass perforating device if the position that punches needs to be adjusted like the structure that CN207747242U discloses, need adjust toughened glass's position, and toughened glass's weight is great, and the time of adjustment position is longer, and efficiency is lower, and has wasted labour personnel's physical power, to sum up, this application now provides a toughened glass perforating device and solves the problem that the aforesaid appears.

Disclosure of Invention

The invention aims to provide a tempered glass punching device to solve the problems in the background technology.

In order to achieve the purpose, the invention provides the following technical scheme: a tempered glass punching device comprises a workbench, support legs and a drill bit, wherein a groove body for placing a tempered glass body is arranged on the workbench, the supporting legs are arranged at the bottom of the workbench, the drill bit is fixedly connected with the output end of the lifting cylinder through a telescopic rod, the drill bit further comprises a second mounting frame, a second sliding block, a first mounting frame and a first sliding block, the second mounting rack is arranged at the side end of the workbench, the second sliding block is connected on the second mounting rack in a sliding manner, the second slide block is in transmission connection with the output end of a second motor through a second stepping drive assembly, the first mounting frame is arranged on one side surface of the second slide block close to the workbench, the first slide block is connected on the first mounting frame in a sliding manner, and the first slider is connected with the output end of the first motor through a first stepping driving assembly in a transmission manner, and the lifting cylinder is arranged at the bottom of the first slider through a mounting seat.

Preferably, still include positioning mechanism, positioning mechanism comprises locating plate, positioning bolt and set nut, the locating plate contacts with the toughened glass body, and positioning bolt runs through locating plate and workstation to fix on the workstation through set nut is detachable.

Preferably, still include lubricated mechanism, lubricated mechanism includes piston cylinder, piston plate, transfer line and oil sprayer, the piston cylinder sets up at the mount pad side, and piston cylinder side top has seted up the through-hole, piston plate sliding connection is at the piston cylinder inner wall, the transfer line is L type structure, and the piston plate passes through transfer line and telescopic link fixed connection, the direction of the export of oil sprayer is towards the direction of drill bit, and the oil sprayer is connected with the interior bottom of piston cylinder.

More preferably, the lubricating mechanism further comprises an oil collecting groove, the oil collecting groove is arranged at the bottom of the workbench, and oil leakage holes are uniformly formed in the contact surface of the oil collecting groove and the workbench.

More preferably, lubricating mechanism still includes filter screen and oil pump, the filter screen sets up and leans on upper portion position in the oil trap, the oil pump sets up the bottom in the oil trap, the output of oil pump is connected with the interior bottom of piston cylinder, and is provided with the check valve on the output tube.

More preferably, lubricating mechanism still includes roof, contact time delay switch and trigger block, the roof sets up top in the piston cylinder, contact time delay switch sets up in the roof bottom, contact time delay switch and oil pump electric connection, the trigger block sets up at piston plate top.

Compared with the prior art, the invention has the beneficial effects that: according to the invention, the first motor is matched with the first stepping driving assembly to adjust the movement of the first sliding block and adjust the longitudinal position of the drill bit, the second motor is matched with the second stepping driving assembly to adjust the movement of the second sliding block and adjust the transverse position of the drill bit, the original mode of adjusting the position of toughened glass is replaced, the punching position is adjusted, and the efficiency is improved; according to the invention, the toughened glass is positioned through the positioning plate, the positioning bolt and the positioning nut, so that the punching effect is improved; according to the invention, the drill bit can be lubricated while drilling through the piston cylinder, the piston plate, the transmission rod and the oil nozzle; according to the invention, redundant lubricating oil is collected after being filtered by the oil collecting tank, the filter screen and the oil pump, and is recycled; the lubricating oil in the oil collecting groove is automatically drawn back into the piston cylinder after being lubricated by the top plate, the contact type time delay switch and the trigger block.

Drawings

FIG. 1 is a schematic structural view of the present invention;

FIG. 2 is a schematic structural view of a positioning mechanism according to the present invention;

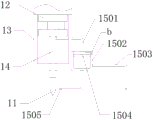

fig. 3, 4 and 5 are schematic structural views of the lubricating mechanism of the present invention.

In the reference symbols: 1. a support leg; 2. a work table; 3. a positioning mechanism; 4. a tempered glass body; 5. a first mounting bracket; 6. a first slider; 7. a first motor; 8. a second slider; 9. a second mounting bracket; 10. a second motor; 11. a drill bit; 12. a lifting cylinder; 13. a mounting seat; 14. a telescopic rod; 15. a lubrication mechanism; 31. positioning a plate; 32. positioning the bolt; 33. positioning a nut; 1501. a transmission rod; 1502. a piston cylinder; 1503. an oil pipe; 1504. a piston plate; 1505. an oil jet; 1506. an oil sump; 1507. a filter screen; 1508. an oil pump; 1509. a top plate; 1510. a trigger block; 1511. a contact type delay switch; a. an oil leak hole; b. and a through hole.

Detailed Description

The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only a part of the embodiments of the present invention, and not all of the embodiments. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

Example one

Referring to fig. 1, the present invention provides a technical solution: a tempered glass punching device comprises a workbench 2, a support leg 1 and a drill bit 11, wherein a groove body for placing a tempered glass body is arranged on the workbench 2, the support leg 1 is arranged at the bottom of the workbench 2, the drill bit 11 is fixedly connected with the output end of a lifting cylinder 12 through a telescopic rod 14, the tempered glass punching device also comprises a second mounting frame 9, a second slider 8, a first mounting frame 5 and a first slider 6, the second mounting frame 9 is arranged at the side end of the workbench 2, the second slider 8 is connected on the second mounting frame 9 in a sliding manner, the second slider 8 is connected with the output end of a second motor 10 in a transmission manner through a second stepping driving assembly, the first mounting frame 5 is arranged on a side surface, close to the workbench 2, of the second slider 8, the first slider 6 is connected on the first mounting frame 5 in a sliding manner, and the first slider 6 is connected with the output end of a first motor 7 in a transmission manner through the first stepping driving, and the lifting cylinder 12 is arranged at the bottom of the first slide block 6 through a mounting seat 13.

The working process is as follows: place the toughened glass body on workstation 2, when needing to adjust drill bit 11 position, operate first motor 7, the output of first motor 7 drives first slider 6 through first step drive subassembly and moves on first mounting bracket 5, adjust the longitudinal position of drill bit 11, and operation second motor 10, the output of second motor 10 drives second slider 8 through second step drive subassembly and moves on second mounting bracket 9, adjust the transverse position of drill bit 11, finally pass through lift cylinder 12 and drive the motion of drill bit 11 through telescopic link 14, accomplish the operation of punching.

Example two

As a preferable scheme of the first embodiment, please refer to fig. 2, further comprising a positioning mechanism 3, wherein the positioning mechanism 3 is composed of a positioning plate 31, a positioning bolt 32 and a positioning nut 33, the positioning plate 31 is in contact with the tempered glass body, and the positioning bolt 32 penetrates through the positioning plate 31 and the worktable 2 and is detachably fixed on the worktable 2 through the positioning nut 33.

The working process is as follows: pass positioning bolt 32 locating plate 31 and workstation 2 to utilize set nut 33 to fix, make locating plate 31 and toughened glass body butt mutually, cooperation workstation 2 is spacing to toughened glass body 4.

EXAMPLE III

As another preferable scheme of the first embodiment, please refer to fig. 3, 4 and 5, further comprising a lubricating mechanism 15, wherein the lubricating mechanism 15 includes a piston cylinder 1502, a piston plate 1504, a transmission rod 1501 and an oil nozzle 1505, the piston cylinder 1502 is disposed at a side end of the mounting seat 13, a through hole b is formed in a top portion of a side surface of the piston cylinder 1502, the piston plate 1504 is slidably connected to an inner wall of the piston cylinder 1502, the transmission rod 1501 is in an L-type structure, the piston plate 1504 is fixedly connected with the telescopic rod 14 through the transmission rod 1501, an outlet of the oil nozzle 1505 faces the direction of the drill bit 11, and the oil nozzle 1505 is connected with an inner bottom portion of the piston cylinder 1502.

Lubricating mechanism 15 still includes oil trap 1506, oil trap 1506 sets up in workstation 2 bottom, and oil leak hole an has evenly been seted up to the contact surface of oil trap 1506 and workstation 2.

Lubricating mechanism 15 still includes filter screen 1507 and oil pump 1503, filter screen 1507 sets up and leans on the upper portion position in oil trap 1506, oil pump 1503 sets up the bottom in oil trap 1506, the output of oil pump 1503 is connected with piston cylinder 1502's interior bottom, and is provided with the check valve on the output tube.

Lubricating mechanism 15 still includes roof 1509, contact delay switch 1511 and trigger block 1510, roof 1509 sets up the top in piston cylinder 1502, contact delay switch 1511 sets up in roof 1509 bottom, contact delay switch 1511 and oil pump 1503 electric connection, trigger block 1510 sets up at piston plate 1504 top.

The working process is as follows: when the telescopic rod 14 moves downwards, the transmission rod 1501 drives the piston plate 1504 to move downwards in the piston cylinder 1502, and the lubricating oil in the piston cylinder 1502 is conveyed to the oil nozzle 1505, and the oil nozzle 1505 sprays the lubricating oil on the surface of the drill bit 11 to lubricate the drill bit 11.

Unnecessary lubricating oil downward flow to inside the oil trap 1506 is got into from oil leak hole a on workstation 2, and filter the back through filter screen 1507, get into the bottom and store in the oil trap 1506, drilling finishes, when drill bit 11 resets, the same reason drives piston plate 1504 at the inside rebound of piston cylinder 1502, after trigger block 1510 contacts with contact delay switch 1511, through-hole b can be opened to piston plate 1504, contact delay switch 1511 control pump body is carried the lubricating oil of bottom back to inside the piston cylinder 1502 in the oil trap 1506, for cyclic use.

While there have been shown and described what are at present considered the fundamental principles and essential features of the invention and its advantages, it will be apparent to those skilled in the art that the invention is not limited to the details of the foregoing exemplary embodiments, but is capable of other specific forms without departing from the spirit or essential characteristics thereof. The present embodiments are therefore to be considered in all respects as illustrative and not restrictive, the scope of the invention being indicated by the appended claims rather than by the foregoing description, and all changes which come within the meaning and range of equivalency of the claims are therefore intended to be embraced therein. Any reference sign in a claim should not be construed as limiting the claim concerned.

Although embodiments of the present invention have been shown and described, it will be appreciated by those skilled in the art that changes, modifications, substitutions and alterations can be made in these embodiments without departing from the principles and spirit of the invention, the scope of which is defined in the appended claims and their equivalents.

Claims (6)

1. A tempered glass punching device comprises:

the tempering glass production line comprises a workbench (2), wherein a groove body for placing a tempered glass body (4) is arranged on the workbench (2);

the support leg (1), the support leg (1) is arranged at the bottom of the workbench (2); and

the drill bit (11), the drill bit (11) is fixedly connected with the output end of the lifting cylinder (12) through a telescopic rod (14);

it is characterized by also comprising:

the second mounting rack (9), the second mounting rack (9) is arranged at the side end of the workbench (2);

the second sliding block (8) is connected to the second mounting frame (9) in a sliding mode, and the second sliding block (8) is in transmission connection with the output end of the second motor (10) through the second stepping driving assembly;

the first mounting rack (5) is arranged on one side surface, close to the workbench (2), of the second sliding block (8); and

first slider (6), first slider (6) sliding connection is on first mounting bracket (5), and first slider (6) are connected through the output transmission of first step drive subassembly with first motor (7), and lift cylinder (12) set up in first slider (6) bottom through mount pad (13).

2. The tempered glass punching device according to claim 1, further comprising a positioning mechanism (3), wherein the positioning mechanism (3) is composed of a positioning plate (31), a positioning bolt (32) and a positioning nut (33), the positioning plate (31) is in contact with the tempered glass body (4), and the positioning bolt (32) penetrates through the positioning plate (31) and the workbench (2) and is detachably fixed on the workbench (2) through the positioning nut (33).

3. The tempered glass punching device according to claim 1, further comprising:

a lubrication mechanism (15), the lubrication mechanism (15) comprising:

the piston cylinder (1502) is arranged at the side end of the mounting seat (13), and the top of the side surface of the piston cylinder (1502) is provided with a through hole (b);

a piston plate (1504), the piston plate (1504) being slidably connected to an inner wall of a piston cylinder (1502);

a drive rod (1501), the drive rod (1501) is L-shaped, and the piston plate (1504) is fixedly connected with the telescopic rod (14) through the drive rod (1501), and

an oil jet (1505), the direction of the outlet of the oil jet (1505) faces the direction of the drill bit (11), and the oil jet (1505) is connected with the inner bottom of the piston cylinder (1502).

4. The tempered glass punching device according to claim 3, wherein the lubricating mechanism (15) further comprises an oil collecting groove (1506), the oil collecting groove (1506) is arranged at the bottom of the workbench (2), and oil leakage holes (a) are uniformly formed in the contact surface between the oil collecting groove (1506) and the workbench (2).

5. A toughened glass perforating device as claimed in claim 4, characterized in that said lubricating means (15) further comprise:

the filter screen (1507), the said filter screen (1507) is set up in the oil trap (1506) and leans on the upper position; and

the oil pump (1503) is arranged at the inner bottom of the oil collecting tank (1506), the output end of the oil pump (1503) is connected with the inner bottom of the piston cylinder (1502), and the output pipe is provided with a one-way valve.

6. A toughened glass perforating device as claimed in claim 5, characterized in that said lubricating means (15) further comprise:

a top plate (1509), the top plate (1509) being disposed at the top inside the piston cylinder (1502);

the contact type delay switch (1511), the contact type delay switch (1511) is arranged at the bottom of the top plate (1509), and the contact type delay switch (1511) is electrically connected with the oil pump (1503); and

a trigger block (1510), the trigger block (1510) disposed on top of the piston plate (1504).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010290708.0A CN111391145B (en) | 2020-04-14 | 2020-04-14 | Toughened glass perforating device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010290708.0A CN111391145B (en) | 2020-04-14 | 2020-04-14 | Toughened glass perforating device |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111391145A true CN111391145A (en) | 2020-07-10 |

| CN111391145B CN111391145B (en) | 2024-06-04 |

Family

ID=71426051

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010290708.0A Active CN111391145B (en) | 2020-04-14 | 2020-04-14 | Toughened glass perforating device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111391145B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113771236A (en) * | 2021-08-17 | 2021-12-10 | 安徽富亚玻璃技术有限公司 | Quick puncher of glass |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104923817A (en) * | 2015-06-25 | 2015-09-23 | 盐城思隆机电有限公司 | Automatic lubrication structure of manual drilling machine |

| CN105171933A (en) * | 2015-09-25 | 2015-12-23 | 嵊州市寰鼎玻璃科技有限公司 | Drilling device used for glass production |

| CN205552899U (en) * | 2016-04-09 | 2016-09-07 | 傅映霞 | Toughened glass perforating machine |

| CN206779514U (en) * | 2017-05-26 | 2017-12-22 | 沈春燕 | A kind of glass mold drilling equipment |

| CN109249272A (en) * | 2018-10-15 | 2019-01-22 | 安徽省潜山县潜源鬃刷有限公司 | A kind of durable type bristle brush brush drilling device |

| DE102017118180A1 (en) * | 2017-08-09 | 2019-02-14 | Cixi City LongCheng Trade Co., Ltd. | A machine tool for drilling glasses |

| CN209551291U (en) * | 2019-03-23 | 2019-10-29 | 贵溪奥杰智能制造有限公司 | Efficient drilling device is used in a kind of production of metal product |

-

2020

- 2020-04-14 CN CN202010290708.0A patent/CN111391145B/en active Active

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104923817A (en) * | 2015-06-25 | 2015-09-23 | 盐城思隆机电有限公司 | Automatic lubrication structure of manual drilling machine |

| CN105171933A (en) * | 2015-09-25 | 2015-12-23 | 嵊州市寰鼎玻璃科技有限公司 | Drilling device used for glass production |

| CN205552899U (en) * | 2016-04-09 | 2016-09-07 | 傅映霞 | Toughened glass perforating machine |

| CN206779514U (en) * | 2017-05-26 | 2017-12-22 | 沈春燕 | A kind of glass mold drilling equipment |

| DE102017118180A1 (en) * | 2017-08-09 | 2019-02-14 | Cixi City LongCheng Trade Co., Ltd. | A machine tool for drilling glasses |

| CN109249272A (en) * | 2018-10-15 | 2019-01-22 | 安徽省潜山县潜源鬃刷有限公司 | A kind of durable type bristle brush brush drilling device |

| CN209551291U (en) * | 2019-03-23 | 2019-10-29 | 贵溪奥杰智能制造有限公司 | Efficient drilling device is used in a kind of production of metal product |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113771236A (en) * | 2021-08-17 | 2021-12-10 | 安徽富亚玻璃技术有限公司 | Quick puncher of glass |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111391145B (en) | 2024-06-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111391145A (en) | Toughened glass perforating device | |

| CN109365605A (en) | A kind of dedicated press machine of ship workpiece | |

| CN219724668U (en) | Fastener perforating device | |

| CN206811222U (en) | Sleeve pipe notching device | |

| CN203622277U (en) | Sucker positioning device for skylight glass mounting-position tool | |

| CN206437821U (en) | Lift cart | |

| CN212021245U (en) | Toughened glass high accuracy perforating device | |

| CN213320973U (en) | Perforating device is used in toughened glass production | |

| CN113510262A (en) | Drilling equipment for machining | |

| CN213731560U (en) | Auxiliary assembly mechanism for seat basin torsion spring of passenger car seat | |

| CN208216066U (en) | A kind of liftable lightweight hydraulic press | |

| CN217452187U (en) | Perforating device is used in refrigeration accessory production and processing | |

| CN219768707U (en) | Toughened glass perforating device | |

| CN213109776U (en) | Unmanned aerial vehicle damping device | |

| CN219967850U (en) | Metal product press fitting equipment with limiting and fixing mechanism | |

| CN221134884U (en) | Movable support for gantry machining center | |

| CN203476292U (en) | Multi-well interaction hydraulic pumping unit | |

| CN220279858U (en) | Stamping die is used in circuit board production | |

| CN110976630A (en) | Sound insulation wallboard one-step forming punching mechanism | |

| CN221365257U (en) | Toughened glass perforating device with edge explosion-proof function | |

| CN221538153U (en) | Auxiliary drilling device for manufacturing automobile parts | |

| CN217498577U (en) | Novel integrated hydraulic system's scissors fork elevating system | |

| CN212942193U (en) | Energy-saving tail gas absorption tower controlling means | |

| CN219639165U (en) | Hydraulic pump station valve assembly with connecting structure | |

| CN220717420U (en) | Hump formula backup pad closing device that punches a hole |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| TA01 | Transfer of patent application right |

Effective date of registration: 20240407 Address after: No. 21 Weisan Road, Shahe City, Xingtai City, Hebei Province, 054000 Applicant after: Shahe Domson Glass Co.,Ltd. Country or region after: China Address before: 236400 South of Linbi Road, Linquan County Industrial Park, Fuyang City, Anhui Province Applicant before: LINQUAN COUNTY QIANGGANG TOUGHENED GLASS CO.,LTD. Country or region before: China |

|

| TA01 | Transfer of patent application right | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |