CN111331044A - Method for researching and matching drawing die of large automobile stamping part - Google Patents

Method for researching and matching drawing die of large automobile stamping part Download PDFInfo

- Publication number

- CN111331044A CN111331044A CN202010058968.5A CN202010058968A CN111331044A CN 111331044 A CN111331044 A CN 111331044A CN 202010058968 A CN202010058968 A CN 202010058968A CN 111331044 A CN111331044 A CN 111331044A

- Authority

- CN

- China

- Prior art keywords

- die

- blank holder

- upper die

- gasket

- pressure regulating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000000034 method Methods 0.000 title claims abstract description 51

- 230000001105 regulatory effect Effects 0.000 claims abstract description 46

- 238000004519 manufacturing process Methods 0.000 claims abstract description 26

- 230000008569 process Effects 0.000 claims abstract description 15

- 238000003825 pressing Methods 0.000 claims abstract description 12

- 238000011160 research Methods 0.000 claims abstract description 9

- 239000000463 material Substances 0.000 claims description 34

- 238000004040 coloring Methods 0.000 claims description 22

- 238000005498 polishing Methods 0.000 claims description 21

- 230000001680 brushing effect Effects 0.000 claims description 13

- 230000007547 defect Effects 0.000 claims description 12

- 238000003754 machining Methods 0.000 claims description 9

- 238000009434 installation Methods 0.000 claims description 6

- 238000012545 processing Methods 0.000 claims description 6

- 238000004080 punching Methods 0.000 claims description 6

- 239000003086 colorant Substances 0.000 claims description 3

- 238000002360 preparation method Methods 0.000 abstract description 4

- 239000011324 bead Substances 0.000 description 3

- 125000006850 spacer group Chemical group 0.000 description 3

- 230000008859 change Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 230000003068 static effect Effects 0.000 description 2

- 230000004075 alteration Effects 0.000 description 1

- 230000033228 biological regulation Effects 0.000 description 1

- 238000004364 calculation method Methods 0.000 description 1

- 230000001276 controlling effect Effects 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000012407 engineering method Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 230000014759 maintenance of location Effects 0.000 description 1

- 238000000465 moulding Methods 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 230000001737 promoting effect Effects 0.000 description 1

- 238000012827 research and development Methods 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 238000004088 simulation Methods 0.000 description 1

- 230000037303 wrinkles Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D—WORKING OR PROCESSING OF SHEET METAL OR METAL TUBES, RODS OR PROFILES WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21D37/00—Tools as parts of machines covered by this subclass

- B21D37/20—Making tools by operations not covered by a single other subclass

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Shaping Metal By Deep-Drawing, Or The Like (AREA)

Abstract

The invention relates to the field of automobile large-scale stamping part research and preparation. A method for researching and matching a drawing die of a large-sized stamping part of an automobile comprises the following steps of researching and matching the drawing die, wherein the drawing die is provided with an upper die, a blank holder and a lower die, and a pressure regulating pad is used in the research and matching process of the upper die and the blank holder: s1, grinding an upper die and a blank holder; and S3, pressing the blank holder to the bottom by the upper die, and then carrying out grinding and matching with the lower die. The method uses a pressure regulating pad and a stroke limiting block of the die as die bedding cushion blocks, and adjusts the gaps between an upper die and a blank holder and between the upper die and a lower die by adjusting the thickness of a first cushion block, thereby achieving the purpose of fast and accurate bedding-in, eliminating the influence of the difference of the balance degrees of different presses, reducing the bedding-in and debugging period of the die and improving the production stability of the drawing die of the large-scale stamping part of the automobile.

Description

Technical Field

The invention relates to the field of automobile large-scale stamping part bedding and laying, in particular to a bedding and laying method for a drawing die of an automobile large-scale stamping part.

Background

The grinding is an important work for improving the appearance and the precision of the stamping part, and the gap between the convex-concave die and the concave-convex die is uniform through manual polishing and polishing by a fitter, so that the precision and the stability of the stamping part are ensured. The die is prepared in two stages: 1. completing the grinding and matching in a die factory; 2. the mold is transported to the automobile host factory for re-matching. The states of the molding press are respectively researched by a die factory and an automobile host factory, and are key factors influencing the research and debugging period.

The traditional method is to mount a cushion block and a gasket after the die is finished. Since the slide of the press is not perfectly horizontal, there will be a certain inclination, which, although slight, will have a great influence on the die-bedding. When using conventional methods for grinding, the die factory press slides are brought into the grinding with a slight inclination. After the well-researched die is transported to an automobile host factory, due to the difference between the state of the slide block of the press and the press of the die factory, a large amount of time is often spent on re-research, and the debugging period of the die is prolonged.

Patent No. ZL201810466293.0 discloses a method for designing a nip surface for a drawing die of an automobile panel, which includes obtaining a thickness variation condition of a blank flowing on the nip surface and a thickness distribution condition of the blank on the final nip surface through a stamping simulation calculation, and dividing the nip surface into a dynamic flow area and a static retention area. The method comprises the steps of obtaining projections of blank edge nodes in a dynamic flow area on a material pressing surface grid at different stamping travel moments, carrying out corresponding movement according to thickness change conditions, constructing new projection nodes, carrying out curve fitting on the projection nodes in the dynamic flow area to form a curve, and constructing a curved surface. And when the final forming is finished, acquiring projection points of the blank grid nodes of the static staying area on the material pressing surface grid, correspondingly moving according to the thickness change condition, constructing new projection nodes, and constructing the curved surface by applying a reverse engineering method.

Therefore, the existing research and preparation methods have defects and need to be improved and improved.

Disclosure of Invention

In view of the defects of the prior art, the invention aims to provide a method for bedding and preparing a drawing die of a large-sized automobile stamping part, which can eliminate the difference of the states of different press sliding blocks when the stamping part is bedding and prepared and improve the bedding and preparing efficiency of the drawing die of the stamping part.

In order to achieve the purpose, the invention adopts the following technical scheme:

a method for researching and matching a drawing die of a large-sized stamping part of an automobile comprises the following steps of researching and matching the drawing die, wherein the drawing die is provided with an upper die, a blank holder and a lower die, and a pressure regulating pad is used in the research and matching process of the upper die and the blank holder:

s1, installing a pressure regulating pad on the blank holder, putting a die on the machine, placing a first material sheet on the blank holder, punching for the first time, and confirming a gap between the upper die and the blank holder; enabling the gap between the upper die and the blank holder to reach the standard, and polishing the reference surface of the upper die by using an oilstone;

s2, installing a first gasket between the pressure adjusting pad and the blank holder, placing a second sheet on the blank holder, brushing color on the front and back surfaces of the second sheet, installing the die on the machine again, simulating the production state, punching again, polishing the surface of the blank holder opposite to the upper die by using oilstone after the blank holder and the first gasket are finely ground to ensure that the coloring reaches the standard, and installing a second gasket between the pressure adjusting pad and the blank holder;

and S3, pressing the blank holder to the bottom by the upper die, and then carrying out grinding and matching with the lower die.

Preferably, the method for preparing the drawing die for the large automobile stamping part includes, in step S1:

s11, installing the pressure adjusting pad on the blank holder, installing a first sheet on a die, brushing color on the front and back sides of the first sheet, stamping for the first time, and determining whether the gap between the upper die and the blank holder reaches the standard, if so, executing the step S12; if not, go to step S13;

s12, polishing the upper die reference surface by using an oilstone when the gap between the upper die and the blank holder reaches the standard;

s13, adjusting basic equipment parameters of the drawing die, and executing the step S11.

Preferably, the method for preparing the drawing die for the large automobile stamping part includes, in step S2:

s21, installing a pressure regulating pad, adding a first gasket between the pressure regulating pad and the blank holder, brushing color on the front side and the back side of the second sheet, machining the die again, and simulating the production state to punch for one time;

s22, judging whether the coloring of the upper die and the blank holder reaches the standard or not, if so, executing a step S23; if not, the blank holder is finely ground, and then the step S21 is executed;

and S23, polishing the surface of the blank holder by using an oilstone, and adding a second gasket between the pressure regulating pad and the blank holder when the coloring condition reaches the standard.

Preferably, in the step S3, a stroke limiting block is used in the process of lapping the upper die and the lower die, and the method specifically includes:

s31, mounting the stroke limiting block for the lower die, and placing a third gasket between the stroke limiting block and the lower die;

s32, operating the die, brushing and matching colors on the surface of the stroke limiting block to simulate the production state and punch once, confirming whether the stroke limiting block is uniformly colored, if so, polishing the reference surface of the lower die by using an oilstone, and executing the step S34; if not, go to step S33;

s33, adjusting basic equipment parameters of the drawing die, and executing the step S32;

s34, a die is arranged on the machine, a third material sheet is arranged in the lower die, and the first pressing of the finished piece is carried out;

s35, confirming whether the finished piece has defects, if so, performing defect processing operation, and executing a step S34; if not, go to step S36;

s36, machining the die again, performing brush color matching on the front face and the back face of the fourth material sheet, placing the material sheet in the lower die, and simulating the production state to punch once;

s37, judging whether the clearance between the upper die and the lower die reaches the standard through coloring, if so, executing a step S38; if not, the upper die is finely ground, and step S36 is executed;

s38, determining whether the coloring condition of the third material sheet reaches the standard or not, if so, polishing the upper die molded surface by using an oilstone; if not, step S36 is executed.

Preferably, the method for developing and matching the drawing die for the large automobile stamping part includes the steps that the blank holder is provided with a pressure regulating pad mounting position, the lower die is provided with a stroke limiting block mounting position, and before the step S1, the method further includes the steps of:

and S0, when the blank holder and the lower die are machined, the machining depth of the installation position of the pressure adjusting pad and the installation position of the stroke limiting block is 0.3-0.5mm relative to the plane where the pressure adjusting pad and the stroke limiting block are respectively located.

Preferably, in the method for lapping and matching the drawing die for the large-sized automobile stamping part, the lapping is to polish the corresponding surface and/or adjust the thickness of the first gasket or the third gasket according to certain requirements.

Preferably, the gap of the method for bedding and preparing the drawing die for the large automobile stamping part reaches the standard that the width of the gap between equipment in bedding and preparing minus the thickness of a material piece is 0-0.2 mm.

Preferably, in the method for grinding and matching the drawing die for the large-sized automobile stamping part, the number of the pressure regulating pads is multiple, and the number of the first gaskets and the number of the second gaskets are the same as the number of the pressure regulating pads; the number of the stroke limiting blocks is multiple, and the number of the third gaskets is the same as that of the stroke limiting blocks.

Preferably, the method for grinding and matching the drawing die for the large automobile stamping part comprises the steps that the first gasket is composed of a plurality of first segments, and the total thickness is 0.3-0.5 mm;

the third gasket is composed of a plurality of third sub-pieces, and the total thickness is 0.3-0.5 mm.

Preferably, in the method for grinding and matching the drawing die for the large-sized automobile stamping part, the thickness of the second gasket is 5% -15% of that of the first material sheet.

Compared with the prior art, the method for lapping and matching the drawing die of the large-sized automobile stamping part uses the pressure regulating pad and the stroke limiting block of the die as the die lapping and matching cushion blocks, and adjusts the gaps between the upper die and the blank holder as well as between the upper die and the lower die by adjusting the thickness of the first cushion block, so that the purpose of fast and accurate lapping and matching is achieved, the influence of different balance degree differences of different presses is eliminated, the die lapping and matching and debugging period is shortened, and the production stability of the drawing die of the large-sized automobile stamping part is improved.

Drawings

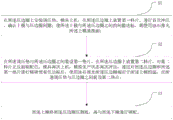

FIG. 1 is a flow chart of a method for researching and matching a drawing die of a large-sized stamping part of an automobile according to an embodiment of the invention.

Detailed Description

In order to make the objects, technical solutions and effects of the present invention clearer and clearer, the present invention is further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described herein are merely illustrative of the invention and are not intended to limit the invention.

Referring to fig. 1, the invention provides a method for lapping a drawing die of a large-sized stamping part of an automobile, which is used for lapping a drawing die, wherein the drawing die is provided with an upper die, a blank holder and a lower die, and a pressure regulating pad is used in the lapping process of the upper die and the blank holder, and comprises the following steps:

s1, installing a pressure regulating pad on the blank holder, putting a die on the machine, placing a first material sheet on the blank holder, punching for the first time, and confirming a gap between the upper die and the blank holder; enabling the gap between the upper die and the blank holder to reach the standard, and polishing the reference surface of the upper die by using an oilstone; specifically, the first material sheet is a square material sheet, the side length is 70-90mm, the thickness is the corresponding thickness of the material sheet used for normally producing corresponding parts in the field, the material sheet is not specifically limited, and the material sheet is mainly used for checking the gap between the upper die and the blank holder to reach the standard, and is placed on the inner side of the pressure regulating pad, and in specific use, in step S1, the gap between the upper die and the blank holder can reach the standard only after the first material sheet is possibly used for checking for multiple times; the pressure regulating pad is used conventionally in the field, mainly the time for installing the pressure regulating pad is used before the research and preparation process, the number is not limited, the pressure regulating pad is specifically adapted according to the size of a drawing die, and the pressure regulating pad is a common pressure regulating pad in the field or a pad type device capable of realizing the same or similar functions of the common pressure regulating pad in the field; the upper die datum plane is used for carrying out the research and preparation work of the upper die and the blank holder by taking the shape of the upper die at the moment as a datum; the stamping stroke of the first stamping is 10-20mm of pressing after the upper die is contacted with the blank holder, and the stamping force applied to the blank holder is 40-50 tons;

s2, installing a first gasket between the pressure adjusting pad and the blank holder, placing a second sheet on the blank holder, brushing color on the front and back surfaces of the second sheet, installing the die on the machine again, simulating the production state, punching again, polishing the surface of the blank holder opposite to the upper die by using oilstone after the blank holder and the first gasket are finely ground to ensure that the coloring reaches the standard, and installing a second gasket between the pressure adjusting pad and the blank holder; specifically, the second material sheet is a normal material sheet for producing the stamping part in a conventional manner, has the same thickness as the first material sheet and different side lengths, is determined according to the size of the stamping part to be manufactured, is generally 2-3m, and is placed on the inner side of the pressure regulating pad; the lapping process is a process of adjusting the surface of the blank holder, which is opposite to the upper die, so as to adapt to the reference surface of the upper die, and the thickness of the first gasket is required to be adjusted in the process so as to achieve the lapping effect; the parameters of the production state are that the stamping stroke is 10-20mm of pressing after the upper die is contacted with the blank holder, and the stamping force applied to the blank holder is the tonnage used in normal production, generally 100-200 tons; the color matching is a common color matching scheme in the field, and generally comprises red lead and blue lead; the coloring standard is a common standard in the field and is not specifically limited, and generally, the coloring standard meets the standard and requires the whole coloring of 'loose outside and tight inside'; the management surface of the blank holder is colored by 100 percent; the coloring of the outside of the draw bead of the blank holder is more than or equal to 85 percent, and the coloring of the area of the outside of the draw bead of the blank holder, which is less than or equal to 30mm, is weaker than the management surface; the area, which is more than or equal to 30mm outside the draw bead, of the blank holder is gradually colorless;

and S3, pressing the blank holder into the lower die by the upper die, and then grinding and matching the blank holder and the lower die.

Preferably, in this embodiment, the step S1 specifically includes:

s11, installing the pressure adjusting pad on the blank holder, installing a first sheet on a die, brushing color on the front and back sides of the first sheet, stamping for the first time, and determining whether the gap between the upper die and the blank holder reaches the standard, if so, executing the step S12; if not, go to step S13; specifically, the standard that the gap meets the standard is that the width of the gap between the upper die and the blank holder minus the thickness of the material sheet is 0-0.2mm, namely the gap meets the standard, and if the width of the gap is greater than or equal to 0.2mm, the gap does not meet the standard; it should be noted here that, here, the first web is mounted such that, every time the step S11 is performed,

s12, polishing the reference surface of the upper die by using an oilstone when the gap between the upper die and the blank holder reaches the standard, and executing the step S2;

s13, adjusting basic equipment parameters of the drawing die, and executing the step S11. It should be noted that, in general, the condition that the gap does not meet the standard may be caused by a fault of a machine tool where the drawing die is located, or a problem of the upper die and the blank holder in the manufacturing process, and therefore, rework is required to readjust parameters of the whole drawing die equipment, and the manufacturing is performed according to a required standard.

Preferably, in this embodiment, the step S2 specifically includes:

s21, installing a pressure regulating pad, adding a first gasket between the pressure regulating pad and the blank holder, brushing color on the front side and the back side of the second sheet, machining the die again, and simulating the production state to punch for one time;

s22, judging whether the coloring of the upper die and the blank holder reaches the standard or not, if so, executing a step S23; if not, performing fine grinding on the blank holder and the first gasket, and then executing the step S21; here, the lapping of the blank holder includes a process of processing the first gasket, the lapping of the blank holder is to polish the blank holder to be adapted to the upper die reference surface, and the lapping of the first gasket is to adjust the height of the first gasket, generally to reduce the first gasket by a certain thickness; in the lapping process, lapping can be carried out on the blank holder and the first gasket at the same time, or can be carried out on a certain device independently;

and S23, polishing the surface of the blank holder by using an oilstone, adding a second gasket between the pressure regulating pad and the blank holder, and executing the step S3. In the mass production process, the mould can appear generating heat, and it is great to tablet infantees influence of blank pressing circle in the production like this, for promoting production stability, increases the second gasket reduces its influence.

As a preferable scheme, in this embodiment, in step S3, using a stroke limiting block in the process of lapping the upper die and the lower die specifically includes:

s31, mounting the stroke limiting block for the lower die, and placing a third gasket between the stroke limiting block and the lower die; the parameter specifications of the third material sheet and the second material sheet are consistent and are not specifically limited; the stroke limiting block is consistent with the basic parameter specification of the pressure regulating pad, and is not specifically limited;

s32, operating the die, brushing and matching colors on the surface of the stroke limiting block to simulate the production state and punch once, confirming whether the stroke limiting block is uniformly colored, if so, polishing the reference surface of the lower die by using an oilstone, and executing the step S34; if not, go to step S33; the production state is a state that the stamping stroke and the stamping force are normal production, the stamping stroke is 100-300mm, and the stamping force is 100-200 tons.

S33, adjusting the section mould or position of the upper mould, adjusting basic equipment parameters of the upper mould (needing to be explained, the precision of a machine tool and the processing precision of the upper mould and the blank holder), and executing the step S32; here, it should be noted that the reason why the coloring is not standard is generally that the machine tool needs to be re-calibrated or the upper die needs to be re-ground and manufactured because the working accuracy of the machine tool and the shape accuracy of the upper die have problems; the machine tool is a device used on a drawing die, can be used for controlling the position movement of the upper die, and is a known technology in the field;

s34, a die is arranged on the machine, a third material sheet is arranged in the lower die, and the first pressing of the finished piece is carried out;

s35, confirming whether the finished piece has defects, if so, performing defect processing operation, and executing a step S34; if not, go to step S36; specifically, the defects include cracks and wrinkles, which can be observed by naked eyes or detected by a machine, when the defects are slight, the defects need to be directly cut off and removed, and if the defects are large, the drawing die needs to be adjusted, for example, the blank holder needs to be adjusted, or production parameters and the shape of a processing material sheet need to be adjusted; adjusting the blank holder comprises the steps of re-polishing, re-lapping and the like on the blank holder, the invention is not particularly limited as long as the defect-free appearance of the first punched finished part can be finally realized;

s36, machining the die again, performing brush color matching on the front face and the back face of the fourth material sheet, placing the material sheet in the lower die, and simulating the production state to punch once; specifically, the specification parameters of the fourth material sheet and the third material sheet are consistent, and are not described in detail; the production state is that the stamping stroke and the stamping force are both in normal production, the general stamping stroke is 100-300mm, and the stamping force is 100-200 tons;

s37, judging whether the clearance between the upper die and the lower die reaches the standard through coloring, if so, executing a step S38; if not, the upper die is finely ground, and step S36 is executed; the coloring standard is that the molded surface of the upper die needs to be colored by more than 85% of the area, and the molded surface of the lower die needs to be colored by more than 85% of the area so that the gap reaches the standard;

s38, determining whether the coloring condition of the third material sheet reaches the standard or not, if so, polishing the upper die molded surface by using an oilstone; if not, step S36 is executed.

Preferably, in this embodiment, the blank holder has a pressure regulating pad mounting position, the lower die has a stroke limiting block mounting position, and before step S1, the method further includes the steps of:

and S0, when the blank holder and the lower die are machined, the machining depth of the installation position of the pressure adjusting pad and the installation position of the stroke limiting block is 0.3-0.5mm relative to the plane where the pressure adjusting pad and the stroke limiting block are respectively located. The cross section area of the pressure regulating pad mounting position is similar to that of the pressure regulating pad in shape and slightly larger in area; compared with the cross section of the stroke limiting block, the cross section of the mounting position of the stroke limiting block is similar in shape and slightly larger in area; said slightly larger is an area where the edge portions are less than 1mm apart.

Specifically, in practical applications, the pressure regulating pad or the stroke limiting block has respective attributes, and generally, the pressure regulating pad or the stroke limiting block is not adjusted in the present invention, that is, the present invention can be completely implemented by using the existing devices in the field, and at this time, if the pressure regulating pad or the stroke limiting block is directly used in the research and development process, in the lapping process, when height adjustment is required, the regulation is not provided, and the control precision is difficult, so that the depths of the pressure regulating pad mounting position and the stroke limiting block mounting position need to be additionally machined by 0.5mm, and the first gasket and the third gasket are conveniently added.

Preferably, in this embodiment, the lapping is to polish the corresponding surface and/or adjust the thickness of the first pad or the third pad according to a certain requirement. Specifically, the lapping is performed according to the step link in which the lapping is performed, for example, after the reference surface of the upper die is determined, the blank holder may be lapped, and meanwhile, the thickness of the first/third spacers is adjusted, and the adjustment is performed according to the specific situation, for example, in the lapping and matching of the upper die and the blank holder, only the thickness of the first spacer needs to be adjusted, generally, the thickness of the first/third spacer is reduced.

Preferably, in this embodiment, the number of the pressure regulating pads is multiple, and the number of the first pads and the number of the second pads are the same as the number of the pressure regulating pads; the number of the stroke limiting blocks is multiple, and the number of the third gaskets is the same as that of the stroke limiting blocks. When the number of the first/third pads is plural, all the first/third pads are reduced by the same thickness during the lapping process of the same step.

Preferably, in this embodiment, the first gasket is composed of a plurality of first segments, and the total thickness is 0.3 to 0.5 mm;

the third gasket is composed of a plurality of third sub-pieces, and the total thickness is 0.3-0.5 mm. The thickness range of the first segment and the third segment is 0.01-0.1mm, for example, the thickness of the first gasket is 0.5mm, and the first gasket may be composed of 4 first segments with the thickness of 0.1mm and 2 first segments with the thickness of 0.05mm, or may be composed of other configurations. The thickness of the first/third gasket is set according to specific implementation conditions, and the invention is not particularly limited; can realize that: and brushing color on the pressure regulating pad or the stroke limiting block, and after the upper die is opened after being contacted with the blank holder and the upper die and the lower die, carrying out voltage-sharing coloring on the color regulating pad or the stroke limiting block. The cross section of the first gasket is the same as that of the pressure regulating pad, and the cross section of the electric three gasket is the same as that of the stroke limiting block.

Preferably, in this embodiment, the thickness of the second gasket is 5% to 15% of the thickness of the first web. The cross section of the second gasket is the same as that of the pressure regulating pad.

It should be understood that equivalents and modifications of the technical solution and inventive concept thereof may occur to those skilled in the art, and all such modifications and alterations should fall within the scope of the appended claims.

Claims (10)

1. The method for researching and matching the drawing die of the large-scale stamping part of the automobile is used for researching and matching the drawing die, wherein the drawing die is provided with an upper die, a blank holder and a lower die, and is characterized in that a pressure regulating pad is used in the research and matching process of the upper die and the blank holder, and comprises the following steps:

s1, installing a pressure regulating pad on the blank holder, putting a die on the machine, placing a first material sheet on the blank holder, punching for the first time, and confirming a gap between the upper die and the blank holder; enabling the gap between the upper die and the blank holder to reach the standard, and polishing the reference surface of the upper die by using an oilstone;

s2, installing a first gasket between the pressure adjusting pad and the blank holder, placing a second sheet on the blank holder, brushing color on the front and back surfaces of the second sheet, installing the die on the machine again, simulating the production state, punching again, polishing the surface of the blank holder opposite to the upper die by using oilstone after the blank holder and the first gasket are finely ground to ensure that the coloring reaches the standard, and installing a second gasket between the pressure adjusting pad and the blank holder;

and S3, pressing the blank holder to the bottom by the upper die, and then carrying out grinding and matching with the lower die.

2. The method for preparing the drawing die for the large automobile stamping part according to claim 1, wherein the step S1 specifically comprises the following steps:

s11, installing the pressure adjusting pad on the blank holder, installing a first sheet on a die, brushing color on the front and back sides of the first sheet, stamping for the first time, and determining whether the gap between the upper die and the blank holder reaches the standard, if so, executing the step S12; if not, go to step S13;

s12, polishing the upper die reference surface by using an oilstone when the gap between the upper die and the blank holder reaches the standard;

s13, adjusting basic equipment parameters of the drawing die, and executing the step S11.

3. The method for preparing the drawing die for the large automobile stamping part according to claim 2, wherein the step S2 specifically comprises the following steps:

s21, installing a pressure regulating pad, adding a first gasket between the pressure regulating pad and the blank holder, brushing color on the front side and the back side of the second sheet, machining the die again, and simulating the production state to punch for one time;

s22, judging whether the coloring of the upper die and the blank holder reaches the standard or not, if so, executing a step S23; if not, the blank holder is finely ground, and then the step S21 is executed;

and S23, polishing the surface of the blank holder by using an oilstone, and adding a second gasket between the pressure regulating pad and the blank holder when the coloring condition reaches the standard.

4. The method for bedding and preparing the drawing die for the large automobile stamping part according to claim 3, wherein in the step S3, a stroke limiting block is used in the bedding and preparing process of the upper die and the lower die, and the method specifically comprises the following steps:

s31, mounting the stroke limiting block for the lower die, and placing a third gasket between the stroke limiting block and the lower die;

s32, operating the die, brushing and matching colors on the surface of the stroke limiting block to simulate the production state and punch once, confirming whether the stroke limiting block is uniformly colored, if so, polishing the reference surface of the lower die by using an oilstone, and executing the step S34; if not, go to step S33;

s33, adjusting basic equipment parameters of the drawing die, and executing the step S32;

s34, a die is arranged on the machine, a third material sheet is arranged in the lower die, and the first pressing of the finished piece is carried out;

s35, confirming whether the finished piece has defects, if so, performing defect processing operation, and executing a step S34; if not, go to step S36;

s36, machining the die again, performing brush color matching on the front face and the back face of the fourth material sheet, placing the material sheet in the lower die, and simulating the production state to punch once;

s37, judging whether the clearance between the upper die and the lower die reaches the standard through coloring, if so, executing a step S38; if not, the upper die is finely ground, and step S36 is executed;

s38, determining whether the coloring condition of the third material sheet reaches the standard or not, if so, polishing the upper die molded surface by using an oilstone; if not, step S36 is executed.

5. The method for developing and drawing die for large automobile stamping parts according to claim 4, wherein the blank holder is provided with a pressure regulating pad mounting position, the lower die is provided with a stroke limiting block mounting position, and before step S1, the method further comprises the following steps:

and S0, when the blank holder and the lower die are machined, the machining depth of the installation position of the pressure adjusting pad and the installation position of the stroke limiting block is 0.3-0.5mm relative to the plane where the pressure adjusting pad and the stroke limiting block are respectively located.

6. A method for lapping and drawing dies for large automobile stamping parts according to any one of claims 1 to 5, wherein the lapping is to grind the corresponding surface and/or to adjust the thickness of the first shim or the third shim according to certain requirements.

7. A method for the tooling of a drawing die for large automobile stampings according to any one of claims 1 to 5 where the gap is dimensioned to be 0-0.2mm wide, minus the thickness of the web, of the gap between the equipment in the tooling.

8. The method for bedding and preparing the drawing die for the large-sized automobile stamping parts according to any one of claims 1 to 5, wherein the number of the pressure regulating pads is multiple, and the number of the first gaskets and the number of the second gaskets are the same as the number of the pressure regulating pads; the number of the stroke limiting blocks is multiple, and the number of the third gaskets is the same as that of the stroke limiting blocks.

9. The method for bedding and preparing a drawing die for large automobile stamping parts according to claim 8, wherein the first gasket is composed of a plurality of first segments, and the total thickness is 0.3-0.5 mm;

the third gasket is composed of a plurality of third sub-pieces, and the total thickness is 0.3-0.5 mm.

10. The method for bedding and preparing a drawing die for large automobile stamping parts as claimed in claim 8, wherein the thickness of the second gasket is 5% -15% of the thickness of the first sheet.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010058968.5A CN111331044B (en) | 2020-01-19 | 2020-01-19 | Method for researching and matching drawing die of large automobile stamping part |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010058968.5A CN111331044B (en) | 2020-01-19 | 2020-01-19 | Method for researching and matching drawing die of large automobile stamping part |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111331044A true CN111331044A (en) | 2020-06-26 |

| CN111331044B CN111331044B (en) | 2022-04-15 |

Family

ID=71175766

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010058968.5A Expired - Fee Related CN111331044B (en) | 2020-01-19 | 2020-01-19 | Method for researching and matching drawing die of large automobile stamping part |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111331044B (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112024735A (en) * | 2020-08-18 | 2020-12-04 | 刁建兵 | Variable grinding method for blank holder of automobile drawing die |

| CN112536359A (en) * | 2020-12-03 | 2021-03-23 | 湘潭屹丰模具制造有限公司 | Door handle position curved surface defect optimization method for vehicle door outer plate |

| CN113280732A (en) * | 2021-04-06 | 2021-08-20 | 广汽本田汽车有限公司 | Method for detecting grinding rate of die |

| CN114378648A (en) * | 2022-01-12 | 2022-04-22 | 广州小鹏汽车科技有限公司 | Die lapping method, die and covering piece |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH02104426A (en) * | 1988-10-12 | 1990-04-17 | Mazda Motor Corp | Manufacture of press die |

| CN101554708A (en) * | 2008-04-11 | 2009-10-14 | 协欣金属工业股份有限公司 | Mould processing and trimming method of automotive sheet metal part |

| CN203316613U (en) * | 2013-05-14 | 2013-12-04 | 瑞鹄汽车模具有限公司 | Stamping die capable of improving lapping-in rate of large covering part |

| CN104001808A (en) * | 2014-06-10 | 2014-08-27 | 南京天河汽车配件有限公司 | Stamping die for automobile exhaust system casing |

| CN204735629U (en) * | 2015-07-07 | 2015-11-04 | 湘潭天汽模热成型技术有限公司 | Mould gasket micromatic setting |

| CN110328275A (en) * | 2019-06-25 | 2019-10-15 | 广州屹丰模具制造有限公司 | The hot forming tool and method of vehicle A column reinforcement plate |

-

2020

- 2020-01-19 CN CN202010058968.5A patent/CN111331044B/en not_active Expired - Fee Related

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH02104426A (en) * | 1988-10-12 | 1990-04-17 | Mazda Motor Corp | Manufacture of press die |

| CN101554708A (en) * | 2008-04-11 | 2009-10-14 | 协欣金属工业股份有限公司 | Mould processing and trimming method of automotive sheet metal part |

| CN203316613U (en) * | 2013-05-14 | 2013-12-04 | 瑞鹄汽车模具有限公司 | Stamping die capable of improving lapping-in rate of large covering part |

| CN104001808A (en) * | 2014-06-10 | 2014-08-27 | 南京天河汽车配件有限公司 | Stamping die for automobile exhaust system casing |

| CN204735629U (en) * | 2015-07-07 | 2015-11-04 | 湘潭天汽模热成型技术有限公司 | Mould gasket micromatic setting |

| CN110328275A (en) * | 2019-06-25 | 2019-10-15 | 广州屹丰模具制造有限公司 | The hot forming tool and method of vehicle A column reinforcement plate |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112024735A (en) * | 2020-08-18 | 2020-12-04 | 刁建兵 | Variable grinding method for blank holder of automobile drawing die |

| CN112024735B (en) * | 2020-08-18 | 2022-06-17 | 刁建兵 | Variable grinding method for blank holder of automobile drawing die |

| CN112536359A (en) * | 2020-12-03 | 2021-03-23 | 湘潭屹丰模具制造有限公司 | Door handle position curved surface defect optimization method for vehicle door outer plate |

| CN112536359B (en) * | 2020-12-03 | 2023-09-29 | 湘潭屹丰模具制造有限公司 | Method for optimizing curved surface defect at door handle position of outer plate of vehicle door |

| CN113280732A (en) * | 2021-04-06 | 2021-08-20 | 广汽本田汽车有限公司 | Method for detecting grinding rate of die |

| CN114378648A (en) * | 2022-01-12 | 2022-04-22 | 广州小鹏汽车科技有限公司 | Die lapping method, die and covering piece |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111331044B (en) | 2022-04-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111331044B (en) | Method for researching and matching drawing die of large automobile stamping part | |

| CN102169521B (en) | Design method for molded surface of automobile cover part die based on molded surface deformation compensation | |

| JP2819177B2 (en) | Press forming progressive bead mold for metal gasket | |

| CN102024081B (en) | Automobile panel die design method | |

| CN110020487B (en) | Deflection deformation compensation method for blank holder of drawing die | |

| CN112077214B (en) | Machining method for functional insert of large stamping die | |

| CN101733339B (en) | Manufacture method of sheets of V-shaped plate heat exchanger | |

| CN103100589B (en) | Scaling method of drawing procedure processing data | |

| CN103639499B (en) | A kind of covering digital-control processing system and method thereof | |

| CN216937993U (en) | Deep drawing die for controllable partition flexible blank pressing | |

| CN201871603U (en) | Blanking die for train braking plate | |

| CN108856529B (en) | Stamping die upper die and material pressing plate part processing method | |

| CN212397850U (en) | Efficient stamping part flexible adjustment shaping die | |

| CN210648049U (en) | Full-automatic adjustable size mould | |

| CN214022873U (en) | Drawing die with novel material pressing structure | |

| CN213704661U (en) | Mold insert and mold for front defrosting panel with appearance dermatoglyph by using same | |

| CN204657267U (en) | Quick-adjustsing terminal die | |

| CN104421281A (en) | Cylindrical positioning pin | |

| CN104249235B (en) | The manufacture method of framework | |

| JP6710406B2 (en) | Press mold, press machine, and mold confirmation method | |

| CN215845142U (en) | Connect sword burr processing structure | |

| CN116618508A (en) | Drawing processing method of automobile covering part | |

| CN211330958U (en) | Variable formula embossing mold utensil | |

| CN210121642U (en) | Composite die structure suitable for bending parts | |

| CN116522697A (en) | Method for calculating mold deformation |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| PP01 | Preservation of patent right |

Effective date of registration: 20220926 Granted publication date: 20220415 |

|

| PP01 | Preservation of patent right | ||

| PD01 | Discharge of preservation of patent |

Date of cancellation: 20230423 Granted publication date: 20220415 |

|

| PD01 | Discharge of preservation of patent | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20220415 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |