CN109683552B - Numerical control machining path generation method on complex point cloud model guided by base curve - Google Patents

Numerical control machining path generation method on complex point cloud model guided by base curve Download PDFInfo

- Publication number

- CN109683552B CN109683552B CN201811427216.0A CN201811427216A CN109683552B CN 109683552 B CN109683552 B CN 109683552B CN 201811427216 A CN201811427216 A CN 201811427216A CN 109683552 B CN109683552 B CN 109683552B

- Authority

- CN

- China

- Prior art keywords

- point

- point cloud

- boundary

- projection

- curve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000000034 method Methods 0.000 title claims abstract description 43

- 238000003754 machining Methods 0.000 title claims abstract description 14

- 238000010276 construction Methods 0.000 claims abstract description 7

- 238000012163 sequencing technique Methods 0.000 claims abstract description 4

- 238000013459 approach Methods 0.000 claims description 3

- 150000001875 compounds Chemical class 0.000 claims description 3

- 238000004519 manufacturing process Methods 0.000 abstract description 18

- 238000012545 processing Methods 0.000 abstract description 10

- 238000005259 measurement Methods 0.000 abstract description 6

- 238000004904 shortening Methods 0.000 abstract description 2

- 238000010586 diagram Methods 0.000 description 7

- 238000013461 design Methods 0.000 description 4

- 238000011161 development Methods 0.000 description 2

- 230000018109 developmental process Effects 0.000 description 2

- 239000011159 matrix material Substances 0.000 description 2

- 241001237728 Precis Species 0.000 description 1

- 230000003044 adaptive effect Effects 0.000 description 1

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 238000000354 decomposition reaction Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000000605 extraction Methods 0.000 description 1

- 230000002452 interceptive effect Effects 0.000 description 1

- 230000009191 jumping Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 238000003672 processing method Methods 0.000 description 1

- 230000011218 segmentation Effects 0.000 description 1

Images

Classifications

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B19/00—Programme-control systems

- G05B19/02—Programme-control systems electric

- G05B19/18—Numerical control [NC], i.e. automatically operating machines, in particular machine tools, e.g. in a manufacturing environment, so as to execute positioning, movement or co-ordinated operations by means of programme data in numerical form

- G05B19/19—Numerical control [NC], i.e. automatically operating machines, in particular machine tools, e.g. in a manufacturing environment, so as to execute positioning, movement or co-ordinated operations by means of programme data in numerical form characterised by positioning or contouring control systems, e.g. to control position from one programmed point to another or to control movement along a programmed continuous path

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P90/00—Enabling technologies with a potential contribution to greenhouse gas [GHG] emissions mitigation

- Y02P90/02—Total factory control, e.g. smart factories, flexible manufacturing systems [FMS] or integrated manufacturing systems [IMS]

Landscapes

- Engineering & Computer Science (AREA)

- Human Computer Interaction (AREA)

- Manufacturing & Machinery (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Automation & Control Theory (AREA)

- Numerical Control (AREA)

Abstract

The invention belongs to the technical field of numerical control machining, and discloses a method for generating a numerical control machining path on a complex point cloud model guided by a base curve. Firstly, extracting and sequencing boundary points of point cloud to form an ordered boundary point sequence curve, and then dividing the ordered boundary point sequence curve into four boundary point sequence curves; constructing a Kosky curved surface according to the four point sequence curves and constructing a guide curve on the base surface; then, offsetting the point cloud by taking the radius of the ball end mill as an offset distance; establishing a least square projection model from a guide point to a point cloud, and giving a weight determination method and a projection direction calculation strategy of a working point of the model; iteratively projecting the guide curve onto the offset point cloud along the calculated projection direction, thereby generating an interference-free tool path. The method of the invention passes through the complex construction process from the point cloud data to the CAD parameter model, and directly carries out tool path planning based on the measured point cloud, thereby effectively shortening the production and manufacturing period from the measurement of the prototype of the part to the manufacture of the part and reducing the cost of processing and manufacturing.

Description

Technical Field

The invention belongs to the technical field of numerical control machining, and particularly relates to a method for generating a numerical control machining path on a complex point cloud model guided by a base curve.

Background

At present, with the rapid development of 3D scanning devices, dense and accurate point clouds can represent the geometry of the physical prototype of a part more finely, and have been applied to various industries, such as Reverse Engineering (RE), Rapid Prototyping (RP), and the like. In order to realize the rapid manufacturing of the physical prototypes of the parts, the traditional processing process is to firstly obtain the measurement point cloud of the part prototype by using contact or non-contact measurement equipment, then reconstruct a parameter CAD model from the point cloud data, and plan a numerical control machining tool path on the CAD model. But reconstruction of the parametric CAD model from the measured data is a complex and time consuming process that accounts for over 60% of the entire design, manufacturing cycle. Although current commercial CAD software such as CATIA, Imageware, etc. provides a reverse design function from point cloud data to a parametric surface, the complex area segmentation of point cloud, splicing and clipping between area patches, approximation accuracy and continuity control depending on the experience of designers, and inevitable model repeated modification caused thereby have severely limited the realization and operation of the numerical control processing method based on the parametric surface when facing the point cloud data and the practical application in manufacturing enterprises. The method goes beyond the complicated construction process from discrete data to a parameter curved surface, and the method for realizing the high-efficiency numerical control machining of the complex curved surface part directly based on the point cloud data is undoubtedly an effective way for breaking through the problems. The chinese invention patent "a tool path direct generation method based on measured data" applied by the present invention by the jangege et al generates a tool path for numerical control machining by using a directional projection method (patent No. CN 102608954 a), but the method is significantly different from the hole-s-base plane and iterative least square projection method which are used by the present invention and can better reflect the shape and characteristics of a curved surface. The document "Zhang YJ, Ge LL.adaptive tool pathgeneration on point-sample surfaces.precis Eng 2011; 591-601. A level set-based point projection technique is proposed to directly generate a tool path on the point cloud. The literature "Liu Y, Xia S, Qian X. direct Numerical Control (NC) path generation from discrete points to continuous points paths ASME Trans, J Computt Inf Sci Eng 2012; 031002-1-12' proposes a method based on moving least squares surface projection. At present, a point cloud model-based numerical control machining path generation method at home and abroad mainly converts scattered point cloud data into a simple Z-map or triangular mesh model, and then generates a tool path by using a cross-section method. The proposed method based on level set projection and moving least square plane projection is also significantly different from the method of the invention of point cloud direct least square iterative projection. The invention aims to find a method for directly generating a tool track on a point cloud measured by a contact or non-contact scanning device, which does not relate to nonlinear optimization and has simple and intuitive mathematical calculation process, overcomes the construction process of a point cloud data CAD parameter model, avoids some problems in the process of model conversion, can effectively shorten the development period of a new product and the production and manufacturing period from the measurement of a part prototype to the manufacture of the part, and reduces the processing and manufacturing cost.

Disclosure of Invention

In order to overcome the defects of the existing method for generating the processing path on the point cloud model, the invention provides a method for generating the numerical control processing path on the complex point cloud model guided by a base curve, and the method for generating the processing path directly based on point cloud data is realized.

The technical scheme of the invention is as follows:

a method for generating a numerical control machining path on a complex point cloud model guided by a base curve comprises the following steps:

step a, extracting boundary points of point cloud and sequencing the boundary points to form an ordered boundary point sequence curve, and then dividing the ordered boundary point sequence curve into four boundary point sequence curves;

the method comprises the following specific steps:

a1. selecting any point p on the point cloud, and establishing a local coordinate system by taking p as an origin, wherein the coordinate system comprisesIs p points and its K neighborhood point set CK(p) a unit vector of a line direction of any one point,is p points and its K neighborhood point set CK(p) the unit normal vector of the fitted plane,is thatAnda vector product of (a);

a2. set K neighborhood points CK(p) projection ontoObtaining a projection point set C in the planeK pro(p) for any one point Representing point p and pointConnecting line and shaft ofThe angle of (d);

a3. calculating all included anglesAnd the difference between two consecutive anglesIf the maximum angular differenceExceeding a specified angle thresholdThen the point p is the boundary point;

a4. sorting the boundary points: finding any point in the boundary point set as the starting boundary pointFind its closest point in the set of boundary pointsThen the vector is processedSearch direction as next boundary point

a5. Order toThen along the search directionFinding distances in a set of boundary pointsNearest boundary pointThen orderUpdating search directionsUntil the initial boundary point is searchedThen the process is terminated;

b, constructing a Kouski curved surface according to the four boundary point sequence curves and constructing a guide curve on the base surface;

the construction equation for the guide curve points is as follows:

in the formula, ri,jDenotes the jth guide point, n, on the ith guide curvei,jA unit normal vector representing the guide point on the base plane;

c, offsetting the point cloud by taking the radius of the ball end mill as an offset distance;

d, establishing a least square projection model from the guide point to the point cloud, determining a projection direction and a weight of a working point participating in calculation of the projection point, and iteratively projecting a guide curve onto the offset point cloud along the calculated projection direction to generate an interference-free tool path;

the method comprises the following specific steps:

d1. the plane least squares projection model of the point-to-point cloud model on the guide curve is:

in the formula, pgIn order to guide the curve points,is point cloud data, wiIs a data pointThe relevant weight factor is determined by formula (5);

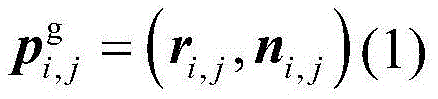

d2. e (d) in formula (2)pro) The condition for obtaining the minimum value is dE (d)pro)/dd pro0, thus obtaining dproComprises the following steps:

d3. the projection direction is as follows:

in the formula:representing the direction vector of the projection, ni,jThe unit normal vector of the guide point on the base plane is represented,representing closest approach on a point cloudPoint of (2)The unit normal vector of (1);

d4. weight factor wjDetermined as follows:

in the formula (I), the compound is shown in the specification,as a guide curve point pgAnd operating pointThe distance between the two adjacent electrodes is less than the total distance,is composed ofAnd a projection line LpThe distance of (d);

d5. and iteratively projecting the guide curve onto the offset point cloud along the calculated projection direction, and terminating iteration when the difference value of two iterations meets the given error precision or reaches the maximum iteration times.

Compared with the prior art, the invention has the beneficial effects that: the invention directly constructs the cutter path based on the measured point cloud, and overcomes the process of point cloud data surface fitting, thereby effectively shortening the production and manufacturing period from the measurement of the part prototype to the manufacture of the part and reducing the design and manufacturing cost.

Drawings

FIG. 1 is a flow chart of the method of the present invention.

FIG. 2 is a schematic diagram of the extraction of point cloud boundary data points.

FIG. 3(a) is a schematic diagram of the ordering of scattered data points.

Fig. 3(b) is a schematic diagram of the division of four boundary point sequence curves.

Fig. 4(a) - (c) are schematic diagrams of point cloud biasing.

Fig. 5 is a schematic diagram of projection direction calculation.

Fig. 6 is an example of the obtained processing path.

Detailed Description

The flow chart of the numerical control machining path generation method on the complex point cloud model guided by the base curve is shown in figure 1. The following detailed description of the embodiments of the invention is provided in conjunction with the accompanying drawings and the implementation steps:

step 1, extracting boundary data points of the point cloud.

Step 1.1. first of allSelecting any point p on the point cloud, and establishing a local coordinate system ξ with p as the origin(L)The position of the lens is determined, in a coordinate system,is p points and its K neighborhood point set CK(p) a unit vector of a line direction of any one point,is the unit normal vector of the plane to which the p points and their K neighborhood point sets are fitted,is thatAndis calculated as the vector product of (a).

Step 1.2, set C of K neighborhood pointsK(p) projection ontoOn the plane, obtaining a projection point set CK pro(p) for any one point Representing point p and pointConnecting line and shaft ofIs represented by the following formula:

step 1.3. calculate neighborhood point set CK(p) angle of each pointAnd calculating the difference between two consecutive anglesIf the maximum angular differenceExceeding a specified angle threshold

The point p is a boundary point. FIG. 2 is a schematic diagram of extracting boundary data points.

Step 1.4, searching all points on the point cloud according to the steps to obtain a boundary point set

And 2, sequencing the boundary data points. Selecting any point in the set of boundary pointsAs starting boundary pointThen, sorting the scattered boundary points according to the following steps:

step 2.1. set of boundary pointsIn searching for distance pointsNearest pointThen the vector is processedSearch direction as next boundary pointAs shown in fig. 3 (a).

Step 2.2. orderThen along the search directionFinding distanceNearest boundary pointAt the same timeThe following should be satisfied:

wherein theta isthIs a specified angle threshold.

Step 2.4. until the initial boundary point is searchedAnd terminating, otherwise, jumping to step 2.2 to continue searching.

Step 3, constructing a Coons base curved surface and a guide curve

Step 3.1, four corner points are designated through interactive operation, the sorted boundary curve obtained in the step 2 is divided into 4 sections of Point Sequence Curves (PSC) by using the four corner points, and as shown in fig. 3(B), each section is fitted by using a cubic B-spline curve:

wherein u is more than or equal to 0, v is less than or equal to 1, r0(u)、r1(u)、r0(v) And r1(v) The compatibility condition of the node vector is satisfied.

The four corner points satisfy the following conditions:

and 3.2, constructing the Coons basal plane through bilinear interpolation of the four boundary curves. The simplest bilinear Coons surface is represented as follows:

r(u,v)=s1(u,v)+s2(u,v)-s3(u,v)(6)

wherein s is1(u, v) and s2(u, v) are each located at r0(u) and r1(u) and r0(v) And r1(v) Linear lofting curve between, s3(u, v) is a tensor product surface, which is a bilinear surface defined by the four corner points in equation (5).

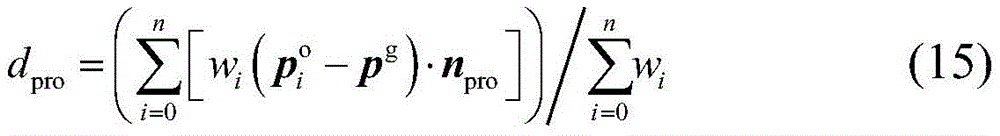

And 3.3, constructing a guide curve point. The construction equation for the guide curve points is as follows:

wherein r isi,jDenotes the jth guide point, n, on the ith guide curvei,jThe unit normal vector of the guide point on the base plane is represented. Record the ith PSC guide curve

Step 4. offset of point cloud

In order to avoid the machining interference between the cutter and the point cloud model, the radius of the cutter of the ball end mill is used as an offset distance for offset, and the offset direction of each data point is the normal direction of the point.

And 4.1, in order to estimate the normal direction of each data point in the point cloud, calculating the covariance matrix of the point set in the K neighborhood of the point. Let CK(p) represents the K neighborhood set of points for point p, then its 3 x 3 covariance matrix HpCalculated from the following formula:

wherein q isj∈CK(p), j ═ 1, …, k. To HpSingular value decomposition is carried out, then HpThe eigenvector corresponding to the minimum eigenvalue is the normal vector n of the p pointpI.e. np=emin. Fig. 4(a) shows the normal vector of the point cloud calculated by the above method.

And 4.2, unifying the directions of the normals, and enabling all the normals to point to the processing side of the point cloud, as shown in fig. 4 (b). Firstly, the normal direction of a point cloud angular point p is consistent with the normal direction of a corresponding angular point on a base surface, and then the normal direction of each neighborhood point of the point p is adjusted, so that the angle between the normal direction of the point p and the normal direction of each neighborhood point of the point p does not exceed a specified angle threshold:

wherein n isp,nneigRespectively the normal directions of the p-point and its neighbours,is an angle threshold, typically less than pi/2 in magnitude.

Step 4.3. offset P of point cloudoffsetCan be calculated from the following formula:

Poffset:po=p+npRc(10)

wherein is RcRadius of the ball nose cutter. FIG. 4(c) is a schematic diagram illustrating the offset of the point cloud

And 5, calculating the projection direction, wherein the projection direction is determined by the following formula as shown in FIG. 5:

in the formulaRepresenting the direction vector of the projection, ni,jThe unit normal vector of the guide point on the base plane is represented,representing closest approach on a point cloudPoint of (2)The unit normal vector of (2).

And 6, establishing a least square projection model from the guide point to the point cloud, and determining a weight factor of the working point.

And 6.1, representing the projection of the guide curve point on the offset point cloud along the projection direction as follows:

qpro=pg+dpronpro(12)

in the formula, qproAs projected points to be solved, dproRepresenting the projection distance, nproIndicating the projection direction.

Step 6.2, a least square projection model from the guide curve point to the point cloud is as follows:

Step 6.3 objective function E (d) in equation (13)pro) The conditions for obtaining the minimum value are:

this makes it possible to obtain:

step 6.4 weight factor wiDetermined by the following formula

In the formula (I), the compound is shown in the specification,for points to be projectedAnd a guide curve point pgThe distance between the two or more of the two or more,is composed ofAnd a projection line LpThe distance of (c). The projection curve equation is as follows:

Lp=pg+tnpro(17)

and 7, iteratively calculating projection points from the guide curve points to the point cloud, and sequentially connecting the projection points to form a tool path.

Step 7.1, selecting the offset point cloud as an initial working point setP0Calculating the projection point q using the equations (12) and (15)pro;

Step 7.2, calculating weight factor { w ] in the first iteration according to the public indication (18)iThreshold value w of }limit;

In the formula, wmeanAnd wmaxAre respectively all weight factors { wiMean and maximum of.

Step 7.3, if the point P in the working point setlWeight factor w ofjGreater than a threshold value wlimitIf yes, keeping the working point set; otherwise, deleting the operation point from the operation point set, thereby updating the operation point set;

and 7.4, calculating projection points in the (l + 1) th iteration according to the new working point setAnd calculates the following iteration end criteria:

In the formula, epsilonprFor a given accuracy of calculation, KmaxIs the maximum number of iterations. If the iteration termination criterion is met, the iteration is terminated; otherwise, updating the point to be projected toThe iteration process continues until the iteration termination criteria are met.

In conclusion, the invention directly constructs the cutter path based on the measured point cloud, and the process from point cloud data to CAD parameter model construction is passed, so that the production period from the measurement of the part prototype to the processing and manufacturing of the part can be effectively shortened, and the design and manufacturing cost is reduced. The high-efficiency tool motion mode can be planned more conveniently on a simple base surface, so that the tool can perform high-efficiency processing on the most appropriate path topology on the point cloud.

Claims (1)

1. A numerical control machining path generation method on a complex point cloud model guided by a base curve is characterized by comprising the following steps:

step a, extracting boundary points of point cloud and sequencing the boundary points to form an ordered boundary point sequence curve, and then dividing the ordered boundary point sequence curve into four boundary point sequence curves;

the method comprises the following specific steps:

a1. selecting any point p on the point cloud, and establishing a local coordinate system by taking p as an origin, wherein the coordinate system comprisesIs p points and its K neighborhood point set CK(p) a unit vector of a line direction of any one point,is p points and its K neighborhood point set CK(p) the unit normal vector of the fitted plane,is thatAnda vector product of (a);

a2. set K neighborhood points CK(p) projection ontoObtaining a projection point set C in the planeK pro(p) for any one point Representing point p and pointConnecting line and shaft ofThe angle of (d);

a3. calculating all included anglesAnd the difference between two consecutive anglesIf the maximum angular differenceExceeding a specified angle thresholdThen the point p is the boundary point;

a4. sorting the boundary points: finding any point in the boundary point set as the starting boundary pointFind its closest point in the set of boundary pointsThen the vector is processedSearch direction as next boundary point

a5. Order toThen along the search directionFinding distances in a set of boundary pointsNearest boundary pointThen orderUpdating search directionsUntil the initial boundary point is searchedThen the process is terminated;

b, constructing a Kouski curved surface according to the four boundary point sequence curves and constructing a guide curve on the base surface;

the construction equation for the guide curve points is as follows:

in the formula, ri,jDenotes the jth guide point, n, on the ith guide curvei,jA unit normal vector representing the guide point on the base plane;

c, offsetting the point cloud by taking the radius of the ball end mill as an offset distance;

d, establishing a least square projection model from the guide point to the point cloud, determining a projection direction and a weight of a working point participating in calculation of the projection point, and iteratively projecting a guide curve onto the offset point cloud along the calculated projection direction to generate an interference-free tool path;

the method comprises the following specific steps:

d1. the plane least squares projection model of the point-to-point cloud model on the guide curve is:

in the formula, pgIn order to guide the curve points,is point cloud data, wiIs a data pointA related weight factor; dproRepresenting the projection distance, nproRepresenting a projection direction;

d2. e (d) in formula (2)pro) The condition for obtaining the minimum value is dE (d)pro)/ddpro0, thus obtaining dproComprises the following steps:

d3. the projection direction is as follows:

in the formula:representing the direction vector of the projection, ni,jThe unit normal vector of the guide point on the base plane is represented,representing closest approach on a point cloudPoint of (2)The unit normal vector of (1);

d4. weight factor wjDetermined as follows:

in the formula (I), the compound is shown in the specification,as a guide curve point pgAnd operating pointThe distance between the two adjacent electrodes is less than the total distance,is composed ofAnd a projection line LpThe distance of (d);

d5. and iteratively projecting the guide curve onto the offset point cloud along the calculated projection direction, and terminating iteration when the difference value of two iterations meets the given error precision or reaches the maximum iteration times.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811427216.0A CN109683552B (en) | 2018-11-27 | 2018-11-27 | Numerical control machining path generation method on complex point cloud model guided by base curve |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811427216.0A CN109683552B (en) | 2018-11-27 | 2018-11-27 | Numerical control machining path generation method on complex point cloud model guided by base curve |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN109683552A CN109683552A (en) | 2019-04-26 |

| CN109683552B true CN109683552B (en) | 2020-04-28 |

Family

ID=66185625

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201811427216.0A Active CN109683552B (en) | 2018-11-27 | 2018-11-27 | Numerical control machining path generation method on complex point cloud model guided by base curve |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN109683552B (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6713700B1 (en) * | 2020-03-09 | 2020-06-24 | リンクウィズ株式会社 | Information processing method, information processing system, program |

| JP6849262B1 (en) * | 2020-05-28 | 2021-03-24 | リンクウィズ株式会社 | Information processing method, information processing system, program |

| CN111806720B (en) * | 2020-06-24 | 2021-12-07 | 成都飞机工业(集团)有限责任公司 | Rectification skin construction method based on measured data of wing body butt joint |

| CN114055253B (en) * | 2021-11-16 | 2023-06-30 | 四川航天长征装备制造有限公司 | Process characteristic measurement construction and processing method for large complex surface part |

| CN114089692B (en) * | 2021-11-18 | 2024-04-19 | 江苏科技大学 | Quick numerical control programming method suitable for complex slender surfaces of parts |

| CN115830269B (en) * | 2022-12-08 | 2023-06-06 | 中铁工程设计咨询集团有限公司 | Tunnel point cloud normal direction adjustment method, device, equipment and readable access medium |

| CN118428696B (en) * | 2024-07-01 | 2024-08-27 | 中川建投集团有限公司 | Civil engineering cost control method based on big data analysis |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4809488B1 (en) * | 2010-05-24 | 2011-11-09 | ファナック株式会社 | Numerical control device with oscillating function capable of changing speed in any section |

| CN102608954A (en) * | 2012-03-26 | 2012-07-25 | 西安交通大学 | Method for directly generating tool path based on measured data |

| CN106054802B (en) * | 2016-07-28 | 2019-04-26 | 电子科技大学 | A kind of free-form surface self-adaptive Toolpath Generation method |

| CN106354098B (en) * | 2016-11-04 | 2018-09-04 | 大连理工大学 | A kind of NURBS composite surfaces are fixed a cutting tool teeth processing route generating method |

| CN108319224B (en) * | 2018-03-13 | 2019-08-13 | 大连理工大学 | A kind of multiaxis NC maching spiral path generation method based on diametral curve interpolation |

-

2018

- 2018-11-27 CN CN201811427216.0A patent/CN109683552B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN109683552A (en) | 2019-04-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109683552B (en) | Numerical control machining path generation method on complex point cloud model guided by base curve | |

| CN110516388B (en) | Harmonic mapping-based curved surface discrete point cloud model circular cutter path generation method | |

| JP4934789B2 (en) | Interpolation processing method and interpolation processing apparatus | |

| CN112284290B (en) | Autonomous measurement method and system for aero-engine blade robot | |

| JP5436416B2 (en) | Approximation processing method and approximation processing apparatus | |

| ElKott et al. | Isoparametric line sampling for the inspection planning of sculptured surfaces | |

| CN114055255B (en) | Large-scale complex component surface polishing path planning method based on real-time point cloud | |

| Li et al. | Arc–surface intersection method to calculate cutter–workpiece engagements for generic cutter in five-axis milling | |

| CN113276130B (en) | Free-form surface spraying path planning method and system based on point cloud slice | |

| CN108682043A (en) | A kind of complex-curved measure planning method based on parameter mapping | |

| CN112033338B (en) | Blade curved surface contact type scanning measurement probe radius surface compensation method | |

| Sieger et al. | A comprehensive comparison of shape deformation methods in evolutionary design optimization | |

| CN109597354A (en) | A kind of multiple constraint numerical control processing track generation method of triangle grid model | |

| CN109343468A (en) | A kind of blade multiaxis orbit generation method based on projection biasing | |

| Jamiolahmadi et al. | Study of detailed deviation zone considering coordinate metrology uncertainty | |

| CN114611359A (en) | Grid-parameter hybrid model modeling method and system | |

| Liu et al. | High precision measurement of blade profile curve using iterative normal vector approximation | |

| Xu et al. | A method of generating spiral tool path for direct three-axis computer numerical control machining of measured cloud of point | |

| Xu et al. | A new welding path planning method based on point cloud and deep learning | |

| Zhang et al. | Efficient sampling method based on co-kriging for free-form surface measurement | |

| CN112381945B (en) | Reconstruction method and system of three-dimensional model transition surface | |

| CN112687010A (en) | Digital metering method for end frame drill jig | |

| Gong et al. | Research on discretization algorithm of free-form surface for robotic polishing | |

| CN116360337A (en) | Point cloud data-based numerical control machining contour parallel tool path generation method | |

| CN111474899A (en) | Triangular-based complex cavity high-speed numerical control milling spiral path generation method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |