Building high-rise escape mechanism based on steel rope

Technical Field

The invention belongs to the technical field of high-rise escape, and particularly relates to a steel rope-based high-rise escape mechanism for a building.

Background

In the use process of the existing high-rise escape mechanism, through the matching of the bearing box and the steel rope, when an emergency occurs in a room, people living in the room need to leave the room quickly through the bearing box and move to the flat ground; however, the currently used carrying box swings when encountering wind in the use process, and the carrying box can collide with the adjacent carrying box in the swinging process; the life safety of people is affected; therefore, it is necessary to design a high-rise escape mechanism for preventing the adjacent carrying boxes from being collided in windy weather.

The invention designs a high-rise building escape mechanism based on steel ropes, which solves the problems.

Disclosure of Invention

In order to solve the defects in the prior art, the invention discloses a steel rope-based high-rise building escape mechanism, which is realized by adopting the following technical scheme.

A building high building escape mechanism based on steel ropes is characterized in that: the device comprises a motor driving device, a first winding wheel, a steel rope, a first support, a first guide mechanism, a first bearing device, a second bearing device and a driving shaft, wherein the motor driving device is arranged on the roof of a high building; the two driving shafts are respectively arranged on the roof of the high-rise building through a first support; the two driving shafts are respectively connected with two output shafts of the motor driving device; the two first winding wheels are respectively arranged on the two driving shafts; the two first guide mechanisms are respectively arranged on two sides of the roof of the high-rise building and are respectively matched with the two first winding wheels; one end of each of the two steel ropes is respectively wound on the two first winding wheels; the other ends of the two steel ropes respectively bypass the two first guide mechanisms and are positioned on one side of the wall; the first bearing device and the second bearing device are respectively connected with the two steel ropes; a plurality of groups of through escape openings are uniformly distributed on the upper part and the lower part of one side surface of the wall close to the first bearing device and the second bearing device; two escape openings in each group of escape openings are respectively matched with the first bearing device and the second bearing device; the escape openings distributed on the wall are matched with the floors.

The first bearing device comprises a steel rope, a bearing box, a detachable hook, a hook mounting groove, an escape inlet, an escape opening, a first partition plate, a second partition plate, a circular shaft hole, a swinging shaft, a swinging block, a triggering plate, a swinging support, a second guide mechanism, a clamping rack, a first support shaft, a second gear, a swinging rod, a volute spiral spring and a second winding wheel, wherein the escape inlet is formed in one side of the bearing box; the other side of the bearing box is provided with 9 hook mounting grooves; the side surface of the bearing box provided with the hook mounting groove is vertical to the side surface provided with the escape inlet; every three hook mounting grooves in the 9 hook mounting grooves are uniformly distributed up and down; the three hook mounting grooves in the same group are uniformly distributed in the transverse direction; an avoidance opening is formed in the upper side surface of the bearing box and is positioned on one side of the bearing box; the first partition plate is arranged on the inner side of the bearing box; the first partition board is parallel to the side surface of the bearing box, which is provided with the escape inlet, and is close to the side surface opposite to the side surface of the bearing box, which is provided with the escape inlet; the second partition plate is arranged on the inner side of the first bearing box and is vertical to the first partition plate; the end surface of the second partition plate, which is close to one side of the bearing box provided with the hook mounting groove; two circular shaft holes are symmetrically formed in the first partition plate and the side face, far away from the escape inlet, in the bearing box; 9 removable couples are installed respectively in 9 couple mounting grooves.

One ends of the two swing supports are symmetrically arranged on the side surface far away from the escape inlet in the bearing box; the other ends of the two swing supports are symmetrically arranged on the first clapboard; the middle position of the swinging rod is provided with a circular hole; the two swing rods are respectively arranged in the bearing box through the matching of the two circular holes on the two swing rods and the two swing supports and are positioned between the first partition plate and the side surface far away from the escape inlet in the bearing box; a volute spiral spring is respectively arranged between the two swinging rods and the side surface far away from the escape inlet in the bearing box; the two volute spiral springs are respectively nested at the outer sides of the two swing supports; the outer ends of the two volute springs are respectively arranged at the two ends of the side surface of the bearing box far away from the escape inlet; the inner ends of the two volute spiral springs are respectively arranged on the two swinging rods; two ends of the clamping rack are respectively connected with the lower ends of the two swing rods through revolute pairs; one end of the first supporting shaft is arranged on the side surface far away from the escape inlet in the bearing box; the second gear is arranged on the first supporting shaft; the second gear is matched with the clamping rack; the second winding wheel is arranged on the first supporting shaft; the second guide mechanism is arranged on the first partition plate and matched with the second winding wheel; a steel rope is wound on the second winding wheel; the other end of the steel rope is connected with one of the two strands of steel ropes wound on the two first winding wheels through a second guide mechanism and an avoidance port on the bearing box; the inner side of the swinging block is provided with a guide through hole; two oscillating shafts are symmetrically arranged on two side surfaces of the oscillating block; the swinging blocks are arranged on the inner side of the bearing box through the matching of the two swinging blocks and the two circular shaft holes and are positioned between the first partition plate and the side surface far away from the escape inlet in the bearing box; the swinging block is nested outside the steel rope in the bearing box through the guide through hole on the swinging block; the two trigger plates are symmetrically arranged on two sides of the swinging block and are respectively matched with the two swinging rods.

The second bearing device is similar to the first bearing device, but in the second bearing device, a hook mounting groove is not formed in the bearing box, and a detachable hook is not arranged; the inner side of the bearing box is not provided with a second clapboard; the side surface of the bearing box is provided with 9 annular buckles; every three of the 9 annular buckles are uniformly distributed up and down; three annular buckles in the same group are uniformly distributed in the transverse direction; the 9 annular buckles are respectively matched with the 9 detachable hooks in the first bearing device.

As a further improvement of the technology, the first guide mechanism comprises an installation notch, an avoiding inclined plane, a guide installation block, a guide support, a guide wheel and a second support shaft, wherein the guide support is installed on the roof of the high-rise and is close to the edge of the roof; one end of the guide support is provided with an installation notch; an avoidance inclined plane is arranged on the upper end surface of one side of the guide support close to the installation gap; one end of the guide mounting block, which is not provided with the mounting notch, is mounted at the upper end of the guide support; two ends of the second supporting shaft are respectively arranged on two side surfaces of the mounting notch; the guide wheel is arranged on the second support shaft; the guide wheel is matched with the steel rope wound on the first winding wheel. The function of the avoidance inclined plane is to prevent the steel rope from interfering with the guide mounting block.

As a further improvement of the technology, the detachable hook comprises a rotating shaft, a hook clamping block, a first plate spring, a U-shaped hook plate, a first support lug and a second support lug, wherein the rotating shaft is arranged on two side surfaces of a hook mounting groove; one end of the U-shaped hook plate is provided with a second lug; the U-shaped hook plate is arranged on the rotating shaft through the second support lug; one end of the hook clamping block is symmetrically provided with two first lugs; the other end of the hook clamping block is provided with a baffle; the hook clamping block is arranged on the rotating shaft through the two first lugs; the hook clamping block is matched with the U-shaped hook plate; a first plate spring is arranged between the hook clamping block and the U-shaped hook plate; the hook clamping block and the U-shaped hook plate are matched with an annular buckle arranged on the second bearing device. The baffle plate is used for reversely separating the hook clamping block from the U-shaped hook plate;

as a further improvement of the present technology, the second guiding mechanism comprises a guiding cylinder, a guiding hole, and a U-shaped supporting plate, wherein the U-shaped supporting plate is mounted on the first partition plate; the bottom end of the U-shaped groove on the U-shaped supporting plate is provided with a circular through hole; the guide cylinder is provided with a through guide hole in the axial direction; the guide cylinder is arranged on the U-shaped supporting plate through a circular through hole on the U-shaped supporting plate; the guide cylinders are nested outside the corresponding steel ropes.

As a further improvement of the technology, the circular surface of the lower side of the guide hole formed on the guide cylinder is provided with a circular arc chamfer. Its function is to reduce the wear on the steel cord.

As a further improvement of the present technology, when the second bearing device and the first bearing device are connected together by the detachable hook and the annular buckle, the swinging of the swinging block makes a right contact between one of the two trigger plates mounted thereon and the corresponding swinging rod, but does not make the swinging rod swing.

The motor driving device is arranged on the roof of a high-rise building; the two driving shafts are respectively arranged on the roof of the high-rise building through a first support; the two driving shafts are respectively connected with two output shafts of the motor driving device; the two first winding wheels are respectively arranged on the two driving shafts; the two first guide mechanisms are respectively arranged on two sides of the roof of the high-rise building and are respectively matched with the two first winding wheels; one end of each of the two steel ropes is respectively wound on the two first winding wheels; the other ends of the two steel ropes respectively bypass the two first guide mechanisms and are positioned on one side of the wall; the first bearing device and the second bearing device are respectively connected with the two steel ropes; a plurality of groups of through escape openings are uniformly distributed on the upper part and the lower part of one side surface of the wall close to the first bearing device and the second bearing device; two escape openings in each group of escape openings are respectively matched with the first bearing device and the second bearing device; escape openings distributed on the wall are matched with floors; one side of the bearing box is provided with an escape inlet; when an emergency occurs in a room, people living in the room need to leave the room quickly and move to the flat ground; but moving speed may be reduced by stairs or elevators; the life safety of people is affected; in the invention, when an emergency occurs in a room, people can enable the bearing box to be matched with the escape opening by adjusting the motor driving device and then enter the bearing box through the escape inlet; the driving motor driving device drives the two first winding wheels to rotate through the rotation of an output shaft of the motor driving device; the two first winding wheels rotate to continuously loosen the steel rope wound on the first winding wheels; simultaneously, the first bearing device and the second bearing device can automatically fall downwards under the action of the gravity of the first bearing device and the second bearing device; until the landing is safe; in the invention, an avoidance port is arranged on the upper side surface of the bearing box and is positioned on one side of the bearing box; the function of the bearing box is to make the gravity center of the bearing box deviate to the wall; the bearing box is always kept in contact with the wall in the downward falling process; the guide support is arranged on the roof of a high building and is close to the edge of the roof; one end of the guide support is provided with an installation notch; an avoidance inclined plane is arranged on the upper end surface of one side of the guide support close to the installation gap; one end of the guide mounting block, which is not provided with the mounting notch, is mounted at the upper end of the guide support; two ends of the second supporting shaft are respectively arranged on two side surfaces of the mounting notch; the guide wheel is arranged on the second support shaft; the guide wheel is matched with a steel rope wound on the first winding wheel; the guide wheel plays a role in guiding the steel rope between the first winding wheel and the bearing box.

In the invention, 9 detachable hooks in a first bearing device are respectively arranged in 9 hook mounting grooves; for the second bearing device, 9 annular buckles are arranged on the side surface of the bearing box; the 9 annular buckles are respectively matched with the 9 detachable hooks in the first bearing device; for the detachable hook, the rotating shaft is arranged on two side surfaces of the hook mounting groove; one end of the U-shaped hook plate is provided with a second lug; the U-shaped hook plate is arranged on the rotating shaft through the second support lug; one end of the hook clamping block is symmetrically provided with two first lugs; the hook clamping block is arranged on the rotating shaft through the two first lugs; the hook clamping block is matched with the U-shaped hook plate; a first plate spring is arranged between the hook clamping block and the U-shaped hook plate; the hook clamping block and the U-shaped hook plate are matched with an annular buckle arranged on the second bearing device; when the bearing box is in use, if the bearing box is windy, the bearing box swings; when the bearing boxes in the first bearing device and the second bearing device are contacted in the swinging process; the 9 ring-shaped buckles arranged in the second bearing device can extrude the hook clamping block arranged in the first bearing device and contacted with the first bearing device; so that the hook clamping block swings; the hook clamping block swings to compress the first plate spring; in the swinging process of the hook clamping block, when the gap between the hook clamping block and the U-shaped hook plate is larger than the width of the annular buckle, the annular buckle can be nested between the U-shaped hook plate and the hook clamping block, and meanwhile, when the hook clamping block loses the extrusion force of the annular buckle, the hook clamping block can restore to the original position to play a limiting role on the annular buckle under the action of the corresponding first plate spring. When the annular buckle in the second bearing device is completely matched with the detachable hook in the first bearing device, the first bearing device and the second bearing device are connected together and swing at the same time; the first bearing device and the second bearing device are prevented from impacting in the swinging process; causing injury to persons located in the first and second carrier means. Two driving shafts are respectively connected with two output shafts of a motor driving device; the function of the device is to ensure that the first bearing device and the second bearing device can keep synchronous in the descending process; so that 9 ring buckles in the second bearing device are completely matched with 9 detachable hooks in the first bearing device; the stability of connection in the process of swinging the first bearing device and the second bearing device together is ensured. The avoidance opening has the function of ensuring that the steel rope cannot interfere with the corresponding bearing box in the swinging process.

One ends of the two swing supports are symmetrically arranged on the side surface far away from the escape inlet in the bearing box; the other ends of the two swing supports are symmetrically arranged on the first clapboard; the middle position of the swinging rod is provided with a circular hole; the two swing rods are respectively arranged in the bearing box through the matching of the two circular holes on the swing rods and the two swing supports; a volute spiral spring is respectively arranged between the two swinging rods and the side surface far away from the escape inlet in the bearing box; the two volute spiral springs are respectively nested at the outer sides of the two swing supports; the outer ends of the two volute springs are respectively arranged at the two ends of the side surface of the bearing box far away from the escape inlet; the inner ends of the two volute spiral springs are respectively arranged on the two swinging rods; two ends of the clamping rack are respectively connected with the lower ends of the two swing rods through revolute pairs; one end of the first supporting shaft is arranged on the side surface far away from the escape inlet in the bearing box; the second gear is arranged on the first supporting shaft; the second gear is matched with the clamping rack; the second winding wheel is arranged on the first supporting shaft; the second guide mechanism is arranged on the first partition plate and matched with the second winding wheel; a steel rope is wound on the second winding wheel; the other end of the steel rope is connected with one of the two strands of steel ropes wound on the two first winding wheels through a second guide mechanism and an avoidance port on the bearing box; the inner side of the swinging block is provided with a guide through hole; two oscillating shafts are symmetrically arranged on two side surfaces of the oscillating block; the swinging blocks are arranged on the inner side of the bearing box through the matching of the two swinging blocks and the two circular shaft holes and are positioned between the first partition plate and the side surface far away from the escape inlet in the bearing box; the swinging block is nested outside the steel rope in the bearing box through the guide through hole on the swinging block; the two trigger plates are symmetrically arranged on two sides of the swinging block and are respectively matched with the two swinging rods; when the second bearing device and the first bearing device are connected with the annular buckle through the detachable hook, the swinging of the swinging block enables one of the two trigger plates installed on the swinging block to be in right contact with the corresponding swinging rod, but the swinging rod cannot swing. When the bearing box is in use, if the bearing box is windy, the bearing box swings; when one of the first bearing device and the second bearing device swings more than the other bearing device, the ring buckle in the second bearing device and the detachable hook in the first bearing device may not be matched, i.e. the first bearing device and the second bearing device are not connected together; thus, the first bearing device and the second bearing device can be impacted; causing injury to persons located in the first and second carrier means. Therefore, when the swing amplitude of one bearing box in the first bearing device and the second bearing device is larger than that of the other bearing box, the swing amplitude of the swing block in the bearing box with large swing amplitude is also increased under the action of the corresponding steel rope; at the moment, the swinging block drives one of the two trigger plates arranged on the swinging block to be in contact with the corresponding swinging rod and enable the swinging rod to swing; the swinging rod swings to enable the clamping rack to swing with the other swinging rod; the latch rack can move upwards while swinging under the action of the two swinging rods; the clamping rack moves upwards to be separated from the corresponding second gear; the clamping rack loses the constraint on the second gear; namely the clamping rack loses the binding of the second winding wheel; therefore, under the action of the steel rope wound on the second winding wheel, the second winding wheel can rotate; the second winding wheel is rotated to loosen the steel rope wound thereon; namely, the length between the steel rope connected with the second winding wheel and the steel rope wound on the corresponding first winding wheel is increased; at the moment, the bearing box with larger swing amplitude can move downwards under the action of self gravity; the bearing boxes in the first bearing device and the second bearing device are contacted and connected with each other in the moving process; swinging together; the first bearing device and the second bearing device are prevented from being impacted in the swinging process; when the first bearing device and the second bearing device are connected together, the swing amplitude of the swing block in the bearing box with larger swing amplitude is reduced; meanwhile, the swinging rod in the bearing box can be restored to the original position under the action of the volute spiral spring, and the second gear is limited again; namely, the second winding wheel is limited again.

Compared with the traditional high-rise escape technology, the high-rise escape mechanism designed by the invention can prevent the adjacent bearing boxes from being impacted and causing damage to people in the bearing boxes by self adjustment when used in windy weather; the safety of the high-rise escape mechanism is improved.

Drawings

Fig. 1 is an external view of an entire part.

Fig. 2 is a schematic view of the overall component distribution.

Fig. 3 is a schematic view of the distribution of the escape opening.

Fig. 4 is a schematic view of the first winding wheel installation.

Fig. 5 is a schematic structural view of the first guide mechanism.

Fig. 6 is a schematic view of a guide wheel installation.

Fig. 7 is an external view of the first carrying device.

Fig. 8 is a schematic distribution diagram of the internal structure of the first carrying device.

Fig. 9 is an external view of the carrying case.

Fig. 10 is a schematic view of the internal structure of the carrying case.

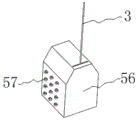

FIG. 11 is a schematic view of hook mounting groove distribution.

FIG. 12 is a schematic view of a detachable hook installation.

FIG. 13 is a schematic view of a detachable hook construction.

Fig. 14 is a schematic view of a hook latch structure.

Fig. 15 is a schematic view of a U-shaped hanger plate structure.

Fig. 16 is a schematic view of the engagement of the rack and the second gear.

Fig. 17 is a schematic illustration of a latch bar installation.

Fig. 18 is a schematic view of trigger plate installation.

Fig. 19 is a second winding wheel installation schematic.

Fig. 20 is a schematic structural view of the second guide mechanism.

FIG. 21 is a swing block installation schematic.

Fig. 22 is a schematic structural view of the second carrying device.

Fig. 23 is a schematic structural view of a carrying case in the second carrying device.

Figure 24 is a schematic view of a buckle installation.

Fig. 25 is a schematic view of a loop fastener configuration.

Number designation in the figures: 1. a motor drive device; 2. a first winding wheel; 3. a steel cord; 4. a first support; 5. a first guide mechanism; 6. a first carrying device; 7. a wall; 8. a second carrying device; 9. an escape opening; 10. a drive shaft; 11. installing a notch; 12. avoiding the inclined plane; 13. a guide mounting block; 14. a guide support; 15. a guide wheel; 16. a second support shaft; 18. a carrying case; 19. the hook can be detached; 20. a hook mounting groove; 23. an escape entrance; 24. avoiding the mouth; 26. a first separator; 27. a second separator; 28. a circular shaft hole; 29. a rotating shaft; 30. a hook clamping block; 31. a first plate spring; 32. a U-shaped hook plate; 33. a first lug; 34. a second lug; 36. a swing shaft; 37. a swing block; 38. a trigger plate; 39. a swinging support; 40. a second guide mechanism; 41. a rack clamping bar; 44. a first support shaft; 45. a second gear; 46. a swing lever; 47. a volute spiral spring; 48. a second winding wheel; 53. a guide cylinder; 54. a guide hole; 55. a U-shaped support plate; 56. an annular buckle; 58. and a guide through hole.

Detailed Description

As shown in fig. 1 and 2, it comprises a motor driving device 1, a first winding wheel 2, a steel cable 3, a first support 4, a first guiding mechanism 5, a first bearing device 6, a second bearing device 8 and a driving shaft 10, wherein as shown in fig. 1, the motor driving device 1 is installed on the roof of a high building; the two driving shafts 10 are respectively arranged on the roof of the high-rise building through a first support 4; as shown in fig. 4, two drive shafts 10 are connected to two output shafts of the motor drive apparatus 1, respectively; the two first winding wheels 2 are respectively mounted on the two driving shafts 10; as shown in fig. 1, two first guiding mechanisms 5 are respectively installed at two sides of the roof of a high-rise building, and the two first guiding mechanisms 5 are respectively matched with two first winding wheels 2; one end of each of the two steel ropes 3 is respectively wound on the two first winding wheels 2; the other ends of the two steel ropes 3 respectively pass around the two first guide mechanisms 5 and are positioned on one side of the wall 7; the first bearing device 6 and the second bearing device 8 are respectively connected with the two steel ropes 3; as shown in fig. 3, a plurality of groups of through escape openings 9 are uniformly distributed on one side surface of the wall 7 close to the first bearing device 6 and the second bearing device 8 from top to bottom; two escape openings 9 in each group of escape openings 9 are respectively matched with the first bearing device 6 and the second bearing device 8; the escape openings 9 distributed on the wall 7 are matched with floors.

As shown in fig. 7 and 8, the first bearing device 6 includes a steel cable 3, a bearing box 18, a detachable hook 19, a hook mounting groove 20, an escape inlet 23, an escape opening 24, a first partition plate 26, a second partition plate 27, a circular shaft hole 28, a swing shaft 36, a swing block 37, a trigger plate 38, a swing support 39, a second guide mechanism 40, a latch bar 41, a first support shaft 44, a second gear 45, a swing rod 46, a volute spring 47, and a second winding wheel 48, wherein as shown in fig. 9, one side of the bearing box 18 is provided with the escape inlet 23; the other side of the bearing box 18 is provided with 9 hook mounting grooves 20; the side surface of the bearing box 18 provided with the hook mounting groove 20 is vertical to the side surface provided with the escape inlet 23; every three of the 9 hook mounting grooves 20 are uniformly distributed up and down; the three hook mounting grooves 20 in the same group are uniformly distributed in the transverse direction; an avoidance opening 24 is formed on the upper side surface of the carrying box 18 and is positioned on one side of the carrying box 18; as shown in fig. 10, the first partition 26 is installed inside the carrying case 18; the first partition plate 26 is parallel to the side surface of the bearing box 18 provided with the escape inlet 23, and is close to the side surface opposite to the side surface of the bearing box 18 provided with the escape inlet 23; as shown in fig. 11, the second partition plate 27 is installed inside the first carrying case 18, and the second partition plate 27 and the first partition plate 26 are perpendicular to each other; the end surface of the second clapboard 27 close to one side of the bearing box 18 provided with the hook mounting groove 20; the first clapboard 26 and the side surface of the bearing box 18 far away from the escape entrance 23 are symmetrically provided with two round shaft holes 28; as shown in fig. 12, 9 detachable hooks 19 are respectively installed in the 9 hook installation grooves 20.

As shown in fig. 8, one ends of the two swing supports 39 are symmetrically installed on the side of the carrying case 18 away from the escape entrance 23; the other ends of the two swing supports 39 are symmetrically mounted on the first partition plate 26; as shown in fig. 17, the swing lever 46 has a circular hole at an intermediate position; the two swinging rods 46 are respectively installed in the bearing box 18 through the matching of the two circular holes on the swinging rods and the two swinging supports 39, and are positioned between the first partition plate 26 and the side surface, far away from the escape entrance 23, in the bearing box 18; as shown in fig. 16, a spiral spring 47 is respectively arranged between the two swing rods 46 and the side surface of the bearing box 18 far away from the escape inlet 23; two scroll springs 47 are respectively nested outside the two swing supports 39; the outer ends of the two volute springs 47 are respectively arranged at two ends of the side surface of the bearing box 18 far away from the escape inlet 23; the inner ends of the two spiral springs 47 are respectively mounted on the two swing levers 46; as shown in fig. 17, both ends of the latch bar 41 are connected to the lower ends of the two swing levers 46 through revolute pairs, respectively; as shown in fig. 21, one end of the first support shaft 44 is mounted on the side of the carrying case 18 away from the escape entrance 23; as shown in fig. 19, the second gear 45 is mounted on the first support shaft 44; the second gear 45 is matched with the latch rack 41; the second winding wheel 48 is mounted on the first support shaft 44; as shown in fig. 16, the second guide mechanism 40 is mounted on the first partition 26, and the second guide mechanism 40 is engaged with the second winding wheel 48; as shown in fig. 8, the second winding wheel 48 is wound with the steel cord 3; the other end of the steel cable 3 is connected with one of the two steel cables 3 wound on the two first winding wheels 2 through the second guide mechanism 40 and the avoidance opening 24 on the bearing box 18; as shown in fig. 18, the inner side of the swing block 37 has a guide through-hole 58; two swing shafts 36 are symmetrically arranged on two side surfaces of the swing block 37; as shown in fig. 21, the swinging block 37 is installed inside the carrying case 18 by the cooperation of the two swinging blocks 37 and the two circular shaft holes 28, and is located between the first partition plate 26 and the side surface of the carrying case 18 far away from the escape entrance 23; the swing block 37 is nested outside the steel rope 3 in the bearing box 18 through the guide through hole 58 on the swing block; as shown in fig. 18, two trigger plates 38 are symmetrically installed on both sides of the swing block 37, and the two trigger plates 38 are respectively engaged with two swing levers 46.

As shown in fig. 22, the second carrying device 8 is similar to the first carrying device 6 except that in the second carrying device 8, as shown in fig. 23, the carrying box 18 is not provided with the hook mounting groove 20 and the detachable hook 19; the inner side of the carrying box 18 is not provided with the second partition plate 27; as shown in fig. 24 and 25, 9 ring-shaped buckles 56 are arranged on the side surface of the carrying box 18; every three of the 9 annular buttons 56 are uniformly distributed up and down; the three annular buttons 56 in the same group are evenly distributed in the transverse direction; the 9 ring clasps 56 are adapted to cooperate with the 9 detachable hooks 19 in the first carrier means 6, respectively.

As shown in fig. 5, the first guide mechanism 5 includes an installation notch 11, an avoiding inclined surface 12, a guide installation block 13, a guide support 14, a guide wheel 15, and a second support shaft 16, wherein the guide support 14 is installed on the top of the high-rise building and near the edge of the top of the building; one end of the guide support 14 is provided with an installation notch 11; as shown in fig. 6, the upper end surface of the guide support 14 on the side close to the installation notch 11 is provided with an avoidance inclined surface 12; one end of the guide mounting block 13, which is not provided with the mounting notch 11, is mounted at the upper end of the guide support 14; two ends of the second supporting shaft 16 are respectively arranged on two side surfaces of the mounting notch 11; the guide wheel 15 is mounted on a second support shaft 16; the guide pulley 15 is engaged with the wire rope 3 wound on the first winding wheel 2. The escape ramp 12 functions to prevent the wire 3 from interfering with the guide mounting block 13.

As shown in fig. 13, the detachable hook 19 includes a rotation shaft 29, a hook latch 30, a first plate spring 31, a U-shaped hook plate 32, a first lug 33, and a second lug 34, wherein the rotation shaft 29 is installed on both side surfaces of the hook installation groove 20; as shown in fig. 15, one end of the U-shaped hanger plate 32 has a second lug 34; the U-shaped hook plate 32 is mounted on the rotation shaft 29 through the second lug 34; as shown in fig. 14, one end of the hooking latch 30 has two first lugs 33 symmetrically; the hook clamping block is arranged on the rotating shaft 29 through two first lugs 33; the hook fixture block is matched with the U-shaped hook plate 32; a first plate spring 31 is arranged between the hook clamping block and the U-shaped hook plate 32; the hook latch and U-shaped hook plate 32 engages with an annular clasp 56 mounted on the second carrier.

As shown in fig. 20, the second guide mechanism 40 includes a guide cylinder 53, a guide hole 54, a U-shaped support plate 55, wherein the U-shaped support plate 55 is mounted on the first partition 26; the bottom end of the U-shaped groove on the U-shaped supporting plate 55 is provided with a circular through hole; the guide cylinder 53 is provided with a through guide hole 54 in the axial direction; the guide cylinder 53 is mounted on the U-shaped support plate 55 through a circular through hole in the U-shaped support plate 55; the guide cylinders 53 are nested outside the corresponding steel cords 3.

The guide cylinder 53 has a circular chamfer on the lower circular surface of the guide hole 54. Its function is to reduce the wear on the steel cord 3.

When the second bearing device 8 and the first bearing device 6 are connected with the ring buckle 56 through the detachable hook 19, the swinging of the swinging block 37 causes the right contact between one of the two trigger plates 38 installed on the swinging block and the corresponding swinging rod 46, but does not cause the swinging of the swinging rod 46.

In summary, the following steps:

when the high-rise escape mechanism designed by the invention is used in windy weather, the adjacent bearing boxes 18 can be prevented from being impacted by self adjustment, so that people in the bearing boxes 18 are prevented from being injured; the safety of the high-rise escape mechanism is improved.

The motor driving device 1 is arranged on the roof of a high-rise building; the two driving shafts 10 are respectively arranged on the roof of the high-rise building through a first support 4; the two drive shafts 10 are respectively connected with two output shafts of the motor drive device 1; the two first winding wheels 2 are respectively mounted on the two driving shafts 10; the two first guide mechanisms 5 are respectively arranged on two sides of the roof of the high-rise building, and the two first guide mechanisms 5 are respectively matched with the two first winding wheels 2; one end of each of the two steel ropes 3 is respectively wound on the two first winding wheels 2; the other ends of the two steel ropes 3 respectively pass around the two first guide mechanisms 5 and are positioned on one side of the wall 7; the first bearing device 6 and the second bearing device 8 are respectively connected with the two steel ropes 3; a plurality of groups of through escape openings 9 are uniformly distributed on one side surface of the wall 7 close to the first bearing device 6 and the second bearing device 8 from top to bottom; two escape openings 9 in each group of escape openings 9 are respectively matched with the first bearing device 6 and the second bearing device 8; escape openings 9 distributed on the wall 7 are matched with floors; one side of the bearing box 18 is provided with an escape inlet 23; when an emergency occurs in a room, people living in the room need to leave the room quickly and move to the flat ground; but moving speed may be reduced by stairs or elevators; the life safety of people is affected; in the invention, when an emergency occurs in a room, people adjust the motor driving device 1 to enable the bearing box 18 to be matched with the escape opening 9, and then enter the bearing box 18 through the escape inlet 23; the driving motor driving device 1 drives the two first winding wheels 2 to rotate through the rotation of an output shaft of the driving motor driving device 1; the two first winding wheels 2 rotate to continuously loosen the steel rope 3 wound on the first winding wheels; meanwhile, the first bearing device 6 and the second bearing device 8 can automatically fall downwards under the action of the gravity of the first bearing device 6 and the second bearing device 8; until the landing is safe; in the invention, an avoidance opening 24 is arranged on the upper side surface of the carrying box 18 and is positioned on one side of the carrying box 18; the function of the bearing box is to bias the center of gravity of the bearing box 18 to the wall 7; so that the carrying case 18 is always kept in contact with the wall 7 during the downward descent; the guide support 14 is arranged on the roof of a high-rise building and is close to the edge of the roof; one end of the guide support 14 is provided with an installation notch 11; an avoidance inclined plane 12 is arranged on the upper end surface of the guide support 14 close to one side of the installation notch 11; one end of the guide mounting block 13, which is not provided with the mounting notch 11, is mounted at the upper end of the guide support 14; two ends of the second supporting shaft 16 are respectively arranged on two side surfaces of the mounting notch 11; the guide wheel 15 is mounted on a second support shaft 16; the guide wheel 15 is matched with the steel rope 3 wound on the first winding wheel 2; the steel cable 3 between the first winding wheel 2 and the carrying case 18 is guided by the guide wheel 15.

In the invention, for the first bearing device 6, 9 detachable hooks 19 are respectively arranged in 9 hook mounting grooves 20; for the second carrier device 8, 9 ring-shaped buckles 56 are arranged on the side surface of the carrier box 18; the 9 annular buckles 56 are respectively matched with the 9 detachable hooks 19 in the first bearing device 6; for the detachable hook 19, the rotating shaft 29 is installed on both side surfaces of the hook installation groove 20; one end of the U-shaped hanger plate 32 has a second lug 34; the U-shaped hook plate 32 is mounted on the rotation shaft 29 through the second lug 34; one end of the hooking latch 30 is symmetrically provided with two first lugs 33; the hook clamping block is arranged on the rotating shaft 29 through two first lugs 33; the hook fixture block is matched with the U-shaped hook plate 32; a first plate spring 31 is arranged between the hook clamping block and the U-shaped hook plate 32; the hook latch and the U-shaped hook plate 32 are matched with an annular buckle 56 arranged on the second bearing device; the carrying case 18 will swing if it encounters wind during use; when the contact occurs between the carrying cases 18 in the first carrying device 6 and the second carrying device 8 during the swinging process; the 9 ring-shaped buckles 56 installed in the second bearing device 8 press the hook latch installed in the first bearing device 6 to contact with it; so that the hook clamping block swings; the first plate spring 31 is compressed by the swinging of the hook clamping block; in the swinging process of the hook clamping block, when the gap between the hook clamping block and the U-shaped hook plate 32 is larger than the width of the annular buckle 56, the annular buckle 56 is nested between the U-shaped hook plate 32 and the hook clamping block, and meanwhile, when the hook clamping block loses the extrusion force of the annular buckle 56, the hook clamping block can restore to the original position to play a limiting role on the annular buckle 56 under the action of the corresponding first plate spring 31. When the ring-shaped buckle 56 in the second bearing device 8 is completely matched with the detachable hook 19 in the first bearing device 6, the first bearing device 6 and the second bearing device 8 are connected together and swing at the same time; the first bearing device 6 and the second bearing device 8 are prevented from being impacted in the swinging process; causing injury to persons located in the first 6 and second 8 carriers. Two driving shafts 10 are respectively connected with two output shafts of the motor driving device 1; the function of the device is to ensure that the first bearing device 6 and the second bearing device 8 can keep synchronous in the descending process; so that the 9 annular buttons 56 in the second carrier means 8 are fully engaged with the 9 detachable hooks 19 in the first carrier means 6; the stability of the connection during the swinging together of the first carrier 6 and the second carrier 8 is ensured. The purpose of the escape opening 24 in the present invention is to ensure that no interference occurs between the steel cable 3 and the corresponding carrying case 18 during the swinging process.

In the invention, one ends of two swinging supports 39 are symmetrically arranged on the side surface far away from the escape entrance 23 in the bearing box 18; the other ends of the two swing supports 39 are symmetrically mounted on the first partition plate 26; the swing lever 46 has a circular hole at an intermediate position; the two swing rods 46 are respectively installed in the bearing box 18 through the matching of the two circular holes on the two swing rods and the two swing supports 39; a scroll spring 47 is respectively arranged between the two swinging rods 46 and the side surface of the bearing box 18 far away from the escape inlet 23; two scroll springs 47 are respectively nested outside the two swing supports 39; the outer ends of the two volute springs 47 are respectively arranged at two ends of the side surface of the bearing box 18 far away from the escape inlet 23; the inner ends of the two spiral springs 47 are respectively mounted on the two swing levers 46; the two ends of the clamping rack bar 41 are respectively connected with the lower ends of the two swing rods 46 through revolute pairs; one end of the first supporting shaft 44 is arranged on the side surface far away from the escape entrance 23 in the bearing box 18; the second gear 45 is mounted on the first support shaft 44; the second gear 45 is matched with the latch rack 41; the second winding wheel 48 is mounted on the first support shaft 44; the second guide mechanism 40 is mounted on the first partition 26, and the second guide mechanism 40 cooperates with the second winding wheel 48; the second winding wheel 48 is wound with a steel rope 3; the other end of the steel cable 3 is connected with one of the two steel cables 3 wound on the two first winding wheels 2 through the second guide mechanism 40 and the avoidance opening 24 on the bearing box 18; the inner side of the swing block 37 has a guide through hole 58; two swing shafts 36 are symmetrically arranged on two side surfaces of the swing block 37; the swinging blocks 37 are arranged on the inner side of the bearing box 18 through the matching of the two swinging blocks 37 and the two circular shaft holes 28 and are positioned between the first partition plate 26 and the side surface, far away from the escape inlet 23, in the bearing box 18; the swing block 37 is nested outside the steel rope 3 in the bearing box 18 through the guide through hole 58 on the swing block; the two trigger plates 38 are symmetrically arranged on two sides of the swinging block 37, and the two trigger plates 38 are respectively matched with the two swinging rods 46; when the second bearing device 8 and the first bearing device 6 are connected with the ring buckle 56 through the detachable hook 19, the swinging of the swinging block 37 causes the right contact between one of the two trigger plates 38 installed on the swinging block and the corresponding swinging rod 46, but does not cause the swinging rod 46 to swing. The carrying case 18 will swing if it encounters wind during use; when one 18 of the first carrying device 6 and the second carrying device 8 swings more than the other 18, the ring buckle 56 of the second carrying device 8 may not be engaged with the detachable hook 19 of the first carrying device 6, i.e. the first carrying device 6 and the second carrying device 8 are not connected together; this makes it possible to cause the first 6 and second 8 carriers to collide; causing injury to persons located in the first 6 and second 8 carriers. Therefore, in the present invention, when the swing amplitude of one carrying box 18 of the first carrying device 6 and the second carrying device 8 is larger than that of the other carrying box 18, the swing amplitude of the swing block 37 in the carrying box 18 with large swing amplitude under the action of the corresponding steel rope 3 is also increased; at this time, the swinging block 37 brings one of the two trigger plates 38 mounted thereon into contact with the corresponding swinging rod 46 and swings the swinging rod 46; the swinging of the swinging rod 46 causes the rack bar 41 and the other swinging rod 46 to swing; the latch rack 41 moves upward while swinging under the action of the two swing levers 46; the rack gear 41 moves upward to be disengaged from the corresponding second gear 45; at this time, the rack-and-pinion 41 loses the binding with the second gear 45; i.e. the rack of catches 41 has lost its grip on the second winding wheel 48; the second winding wheel 48 is rotated by the wire 3 wound around the second winding wheel 48; the second winding wheel 48 rotates to release the steel cord 3 wound thereon; that is, the length between the steel cord 3 connected to the second winding wheel 48 and the steel cord 3 wound on the corresponding first winding wheel 2 is increased; at this time, the bearing box 18 with larger swing amplitude moves downwards under the action of self gravity; the carrying boxes 18 in the first carrying device 6 and the second carrying device 8 are contacted and connected with each other during the moving process; swinging together; the first bearing device 6 and the second bearing device 8 are prevented from impacting in the swinging process; when the first bearing device 6 and the second bearing device 8 are connected together, the swing amplitude of the swing block 37 in the bearing box 18 with larger swing amplitude is reduced; meanwhile, the swing rod 46 in the bearing box 18 is restored to the original position under the action of the volute spiral spring 47, and the second gear 45 is limited again; i.e. again limiting the second winding wheel 48.

The specific implementation mode is as follows: when people use the high-rise escape mechanism designed by the invention and an emergency occurs in a room, people enable the bearing box 18 to be matched with the escape opening 9 by adjusting the motor driving device 1 and then enter the bearing box 18 through the escape inlet 23; the driving motor driving device 1 drives the two first winding wheels 2 to rotate through the rotation of an output shaft of the driving motor driving device 1; the two first winding wheels 2 rotate to continuously loosen the steel rope 3 wound on the first winding wheels; meanwhile, the first bearing device 6 and the second bearing device 8 can automatically fall downwards under the action of the gravity of the first bearing device 6 and the second bearing device 8; until the landing is safe; the carrying case 18 will swing if it encounters wind during use; when the contact occurs between the carrying cases 18 in the first carrying device 6 and the second carrying device 8 during the swinging process; the 9 ring-shaped buckles 56 installed in the second bearing device 8 press the hook latch installed in the first bearing device 6 to contact with it; so that the hook clamping block swings; the first plate spring 31 is compressed by the swinging of the hook clamping block; in the swinging process of the hook clamping block, when the gap between the hook clamping block and the U-shaped hook plate 32 is larger than the width of the annular buckle 56, the annular buckle 56 is nested between the U-shaped hook plate 32 and the hook clamping block, and meanwhile, when the hook clamping block loses the extrusion force of the annular buckle 56, the hook clamping block can restore to the original position to play a limiting role on the annular buckle 56 under the action of the corresponding first plate spring 31. When the ring-shaped buckle 56 in the second bearing device 8 is completely matched with the detachable hook 19 in the first bearing device 6, the first bearing device 6 and the second bearing device 8 are connected together and swing at the same time; the first bearing device 6 and the second bearing device 8 are prevented from being impacted in the swinging process; causing injury to persons located in the first 6 and second 8 carrier devices; if the amplitude of the swing of one of the carrying boxes 18 in the first carrying device 6 and the second carrying device 8 is larger than that of the other carrying box 18 in the swing process, the swing amplitude of the swing block 37 in the carrying box 18 with large swing amplitude under the action of the corresponding steel rope 3 is also increased; at this time, the swinging block 37 brings one of the two trigger plates 38 mounted thereon into contact with the corresponding swinging rod 46 and swings the swinging rod 46; the swinging of the swinging rod 46 causes the rack bar 41 and the other swinging rod 46 to swing; the latch rack 41 moves upward while swinging under the action of the two swing levers 46; the rack gear 41 moves upward to be disengaged from the corresponding second gear 45; at this time, the rack-and-pinion 41 loses the binding with the second gear 45; i.e. the rack of catches 41 has lost its grip on the second winding wheel 48; the second winding wheel 48 is rotated by the wire 3 wound around the second winding wheel 48; the second winding wheel 48 rotates to release the steel cord 3 wound thereon; that is, the length between the steel cord 3 connected to the second winding wheel 48 and the steel cord 3 wound on the corresponding first winding wheel 2 is increased; at this time, the bearing box 18 with larger swing amplitude moves downwards under the action of self gravity; the carrying boxes 18 in the first carrying device 6 and the second carrying device 8 are contacted and connected with each other during the moving process; swinging together; the first bearing device 6 and the second bearing device 8 are prevented from impacting in the swinging process; when the first bearing device 6 and the second bearing device 8 are connected together, the swing amplitude of the swing block 37 in the bearing box 18 with larger swing amplitude is reduced; meanwhile, the swing rod 46 in the bearing box 18 is restored to the original position under the action of the volute spiral spring 47, and the second gear 45 is limited again; i.e. again limiting the second winding wheel 48.