CN107003570B - Liquid crystal display element - Google Patents

Liquid crystal display element Download PDFInfo

- Publication number

- CN107003570B CN107003570B CN201580063916.4A CN201580063916A CN107003570B CN 107003570 B CN107003570 B CN 107003570B CN 201580063916 A CN201580063916 A CN 201580063916A CN 107003570 B CN107003570 B CN 107003570B

- Authority

- CN

- China

- Prior art keywords

- liquid crystal

- group

- formula

- carbon atoms

- display element

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F2/00—Processes of polymerisation

- C08F2/44—Polymerisation in the presence of compounding ingredients, e.g. plasticisers, dyestuffs, fillers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G73/00—Macromolecular compounds obtained by reactions forming a linkage containing nitrogen with or without oxygen or carbon in the main chain of the macromolecule, not provided for in groups C08G12/00 - C08G71/00

- C08G73/06—Polycondensates having nitrogen-containing heterocyclic rings in the main chain of the macromolecule

- C08G73/10—Polyimides; Polyester-imides; Polyamide-imides; Polyamide acids or similar polyimide precursors

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08G—MACROMOLECULAR COMPOUNDS OBTAINED OTHERWISE THAN BY REACTIONS ONLY INVOLVING UNSATURATED CARBON-TO-CARBON BONDS

- C08G77/00—Macromolecular compounds obtained by reactions forming a linkage containing silicon with or without sulfur, nitrogen, oxygen or carbon in the main chain of the macromolecule

- C08G77/04—Polysiloxanes

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1334—Constructional arrangements; Manufacturing methods based on polymer dispersed liquid crystals, e.g. microencapsulated liquid crystals

-

- G—PHYSICS

- G02—OPTICS

- G02F—OPTICAL DEVICES OR ARRANGEMENTS FOR THE CONTROL OF LIGHT BY MODIFICATION OF THE OPTICAL PROPERTIES OF THE MEDIA OF THE ELEMENTS INVOLVED THEREIN; NON-LINEAR OPTICS; FREQUENCY-CHANGING OF LIGHT; OPTICAL LOGIC ELEMENTS; OPTICAL ANALOGUE/DIGITAL CONVERTERS

- G02F1/00—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics

- G02F1/01—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour

- G02F1/13—Devices or arrangements for the control of the intensity, colour, phase, polarisation or direction of light arriving from an independent light source, e.g. switching, gating or modulating; Non-linear optics for the control of the intensity, phase, polarisation or colour based on liquid crystals, e.g. single liquid crystal display cells

- G02F1/133—Constructional arrangements; Operation of liquid crystal cells; Circuit arrangements

- G02F1/1333—Constructional arrangements; Manufacturing methods

- G02F1/1337—Surface-induced orientation of the liquid crystal molecules, e.g. by alignment layers

Landscapes

- Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- Nonlinear Science (AREA)

- Organic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Polymers & Plastics (AREA)

- Medicinal Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Optics & Photonics (AREA)

- Crystallography & Structural Chemistry (AREA)

- General Physics & Mathematics (AREA)

- Mathematical Physics (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Dispersion Chemistry (AREA)

- Liquid Crystal (AREA)

- Polymerisation Methods In General (AREA)

- Macromolecular Compounds Obtained By Forming Nitrogen-Containing Linkages In General (AREA)

- Addition Polymer Or Copolymer, Post-Treatments, Or Chemical Modifications (AREA)

Abstract

The invention provides a liquid crystal display element which has high vertical alignment of liquid crystal, good transparency when no voltage is applied and scattering property when voltage is applied, and high adhesion with a liquid crystal layer. A liquid crystal display element comprising a liquid crystal layer between a pair of substrates having electrodes, at least one of the substrates having a liquid crystal alignment film for vertically aligning the liquid crystal, wherein the liquid crystal layer is obtained by curing a liquid crystal composition comprising a liquid crystal and a polymerizable compound, which is disposed between the pair of substrates, by irradiating the liquid crystal composition with ultraviolet light, and the liquid crystal composition contains a compound represented by the formula [1]]The compound, wherein the liquid crystal alignment film is obtained from a liquid crystal alignment treatment agent containing a polymer having the formula [2-1]]Or formula [2-2]Side chain structures as shown. (X)1: formula [1-a]-formula [1-g]Etc.; x2、X3、X4And X6: a single bond, etc.; x5And X7: benzene rings, etc.; x8:C1~18Alkyl of (e) (X) and the like)A: h, etc.; xB: benzene rings, etc.; xC:C1~18Alkyl of (e) (Y) and the like) (Y1、Y2And Y3: a single bond, etc.; y is4And Y5: benzene rings, etc.; y is6:C1~18Alkyl of (e) (Y) and the like) (Y7: a single bond, etc.; y is8:C8~22Alkyl groups of (ii), etc.).

Description

Technical Field

The present invention relates to a transmission/scattering type liquid crystal display element which exhibits a transmission state when no voltage is applied and exhibits a scattering state when a voltage is applied.

Background

As a liquid crystal display element using a liquid crystal material, a TN (twisted nematic) mode is actually used. This mode utilizes the optical rotation characteristics of liquid crystal for switching light, and requires the use of a polarizing plate when used as a liquid crystal display element. However, the use efficiency of light becomes low due to the use of the polarizing plate.

As a Liquid crystal display element having high light utilization efficiency without using a polarizing plate, there is a Liquid crystal display element that switches between a transmissive state (also referred to as a transparent state) and a scattering state of a Liquid crystal, and generally, a Liquid crystal display element using a polymer Dispersed Liquid crystal (also referred to as a pdlc (polymer Dispersed Liquid crystal) or a polymer Network Liquid crystal (pnlc) is known.

A liquid crystal display element using these elements is formed by having a liquid crystal layer between a pair of substrates provided with electrodes, and performing the following operations: a liquid crystal composition containing a polymerizable compound that is polymerized by ultraviolet rays is disposed between the pair of substrates, and the liquid crystal composition is cured by irradiation with ultraviolet rays, thereby forming a liquid crystal layer, that is, a cured product composite (for example, a polymer network) of liquid crystal and the polymerizable compound. The liquid crystal display element controls the transmission state and the scattering state of the liquid crystal by applying a voltage.

A conventional liquid crystal display element using PDLC or PNLC is a liquid crystal display element (also referred to as a normal (normal) type element) in which liquid crystal molecules are oriented in random directions to be in a white turbid (scattering) state when no voltage is applied, and liquid crystal molecules are aligned in an electric field direction to transmit light when a voltage is applied, thereby being in a transmissive state. However, since the standard type element requires a constant voltage application in order to obtain a transmissive state, power consumption is increased in many applications in which the element is used in a transparent state, for example, when the element is used as a window glass or the like.

On the other hand, a liquid crystal display element (also referred to as a reverse type element) using PDLC which exhibits a transmissive state when no voltage is applied and exhibits a scattering state when a voltage is applied has been proposed (for example, see patent document 1 or patent document 2).

Documents of the prior art

Patent document

Patent document 1: japanese patent No. 2885116

Patent document 2: japanese patent No. 4132424

Disclosure of Invention

Problems to be solved by the invention

The polymerizable compound in the liquid crystal composition of the reverse cell has a function of forming a polymer network to obtain a desired optical characteristic and a function as a curing agent for improving the adhesion between the liquid crystal layer and the liquid crystal alignment film (also referred to as a vertical liquid crystal alignment film). In order to improve the adhesion to the liquid crystal alignment film, it is necessary to make the polymer network denser, but when the polymer network is made denser, there are problems that the vertical alignment of the liquid crystal is inhibited, and the optical characteristics of the reverse type element, that is, the transparency when no voltage is applied and the scattering characteristics when a voltage is applied are deteriorated. Therefore, the liquid crystal composition used in the reverse type device needs to have high liquid crystal vertical alignment properties when forming a liquid crystal layer.

Further, since the liquid crystal alignment film used in the reverse cell is a film having high hydrophobicity for vertically aligning the liquid crystal, there is a problem that the adhesion between the liquid crystal layer and the liquid crystal alignment film is low. Therefore, a large amount of polymerizable compound having a curing agent action must be introduced into the liquid crystal composition used for the retroreflective element. However, when a large amount of polymerizable compound is introduced, the vertical alignment of the liquid crystal is inhibited, and the transparency when no voltage is applied and the scattering property when a voltage is applied are significantly reduced. Therefore, the liquid crystal alignment film used in the reverse device must have high liquid crystal vertical alignment properties.

The present invention aims to provide a liquid crystal display element having high vertical alignment properties of liquid crystal, good optical properties, that is, good transparency when no voltage is applied and good scattering properties when a voltage is applied, and having high adhesion between a liquid crystal layer and a liquid crystal alignment film.

Means for solving the problems

The present inventors have conducted intensive studies to achieve the above object, and as a result, have completed the present invention.

That is, the present invention is a liquid crystal display element including a liquid crystal layer between a pair of substrates having electrodes, at least one of the substrates including a liquid crystal alignment film for vertically aligning the liquid crystal, the liquid crystal layer being obtained by disposing a liquid crystal composition including a liquid crystal and a polymerizable compound between the pair of substrates and curing the composition by irradiation with ultraviolet rays, the liquid crystal composition being a liquid crystal composition containing a compound represented by the following formula [1], and the liquid crystal alignment film being a liquid crystal alignment film obtained from a liquid crystal alignment treatment agent including a polymer having a side chain structure represented by the following formula [2-1] or formula [2-2 ].

(X1Is represented by a formula [1-a ] selected from]-formula [1-g]At least 1 of the group consisting of. X2Represents a group selected from the group consisting of a single bond, -O-, -NH-, -N (CH)3)-、-CH2O-、-CONH-、-NHCO-、-CON(CH3)-、-N(CH3) At least 1 bonding group selected from the group consisting of CO-, -COO-and-OCO-. X3Represents a single bond or- (CH)2)a- (a is an integer of 1 to 15). X4Represents a group selected from the group consisting of a single bond, -O-, -OCH2-, -COO-and-OCO-are used. X5A benzene ring, a cyclohexane ring, or a C17-51 organic group having a steroid skeleton, wherein any hydrogen atom on the benzene ring or the cyclohexane ring is optionally substituted by a C1-3 alkyl group, a C1-3 alkoxy group, a C1-3 fluoroalkyl group, or a C1-3 fluoroalkyl groupFluoroalkoxy or fluorine atom. X6Represents a group selected from the group consisting of a single bond, -O-, -OCH2-、-CH2At least 1 bonding group selected from the group consisting of O-, -COO-and-OCO-. X7Represents a benzene ring or a cyclohexane ring, and any hydrogen atom in these cyclic groups is optionally substituted with an alkyl group having 1 to 3 carbon atoms, an alkoxy group having 1 to 3 carbon atoms, a fluorine-containing alkyl group having 1 to 3 carbon atoms, a fluorine-containing alkoxy group having 1 to 3 carbon atoms or a fluorine atom. p represents an integer of 0 to 4. X8Represents at least 1 selected from the group consisting of C1-18 alkyl, C1-18 fluorinated alkyl, C1-18 alkoxy and C1-18 fluorinated alkoxy. )

(XARepresents a hydrogen atom or a benzene ring. XBRepresents at least 1 cyclic group selected from the group consisting of a benzene ring, a cyclohexane ring and a heterocyclic ring. XCRepresents at least 1 selected from the group consisting of C1-18 alkyl, C1-18 fluorinated alkyl, C1-18 alkoxy and C1-18 fluorinated alkoxy. )

(Y1And Y3Each independently represents a group selected from a single bond, - (CH)2)a- (a is an integer of 1 to 15), -O-, -CH2At least 1 bonding group selected from the group consisting of O-, -COO-and-OCO-. Y is2Represents a single bond or- (CH)2)b- (b is an integer of 1 to 15). Y is4At least 1 2-valent cyclic group selected from the group consisting of benzene ring, cyclohexane ring and heterocycle, or a 2-valent organic group having 17 to 51 carbon atoms and having a steroid skeleton, wherein any hydrogen atom on the cyclic group is optionally substituted by an alkyl group having 1 to 3 carbon atoms, an alkoxy group having 1 to 3 carbon atoms, a fluorine-containing alkyl group having 1 to 3 carbon atoms, a fluorine-containing alkoxy group having 1 to 3 carbon atoms or a fluorine atom. Y is5Represents at least 1 cyclic group selected from the group consisting of a benzene ring, a cyclohexane ring and a heterocyclic ring, these ringsAny hydrogen atom in the cyclic group is optionally substituted by an alkyl group having 1 to 3 carbon atoms, an alkoxy group having 1 to 3 carbon atoms, a fluoroalkyl group having 1 to 3 carbon atoms, a fluoroalkoxy group having 1 to 3 carbon atoms or a fluorine atom. n represents an integer of 0 to 4. Y is6Represents at least 1 selected from the group consisting of C1-18 alkyl, C1-18 fluorinated alkyl, C1-18 alkoxy and C1-18 fluorinated alkoxy. )

-Y7-Y8[2-2]

(Y7Represents a group selected from the group consisting of a single bond, -O-, -CH2O-、-CONH-、-NHCO-、-CON(CH3)-、-N(CH3) At least 1 bonding group selected from the group consisting of CO-, -COO-and-OCO-. Y is8Represents an alkyl group having 8 to 22 carbon atoms or a fluoroalkyl group having 6 to 18 carbon atoms. )

ADVANTAGEOUS EFFECTS OF INVENTION

According to the present invention, a reverse type element having excellent optical characteristics, that is, excellent transparency when no voltage is applied and excellent scattering characteristics when a voltage is applied, and having high adhesion between a liquid crystal layer and a liquid crystal alignment film can be provided. The mechanism by which the liquid crystal display element having the above-described excellent characteristics can be obtained by the present invention is not clear, and is estimated roughly as follows.

The liquid crystal composition used in the present invention comprises a liquid crystal, a polymerizable compound and the compound represented by the formula [1]]The compounds shown. Formula [1]The specific compound has a site having a rigid structure such as a benzene ring or a cyclohexane ring and the formula [1]]X in (1)1The sites where polymerization reaction occurs by ultraviolet rays are shown. Therefore, when the specific compound is contained in the liquid crystal composition, the portion of the rigid structure of the specific compound improves the vertical alignment property of the liquid crystal, and further, the portion where the polymerization reaction occurs reacts with the polymerizable compound, thereby improving the stability of the vertical alignment property of the liquid crystal. Thus, even when the polymer network is densified to improve adhesion to the liquid crystal alignment film, the vertical alignment of the liquid crystal is not inhibited, and a reverse type element exhibiting good optical characteristics can be obtained.

Further, the liquid crystal alignment film used in the present invention is obtained from a liquid crystal alignment treatment agent containing a polymer having a side chain structure represented by the aforementioned formula [2-1] or formula [2-2 ]. In particular, since the specific side chain structure represented by the formula [2-1] shows a rigid structure, a liquid crystal display element obtained using a liquid crystal alignment film having the side chain structure can obtain a high and stable liquid crystal vertical alignment property. Therefore, when a specific side chain structure represented by the formula [2-1] is used, a reverse type element exhibiting excellent optical characteristics can be obtained.

In this way, the liquid crystal display element provided with the liquid crystal alignment film obtained from the liquid crystal alignment treatment agent of the present invention, which contains a liquid crystal composition and a specific polymer having a specific side chain structure, has good optical properties, that is, good transparency when no voltage is applied and good scattering properties when a voltage is applied, and further has high adhesion between the liquid crystal layer and the liquid crystal alignment film.

Detailed Description

< liquid Crystal display element >

The liquid crystal display element of the present invention is a liquid crystal display element having a liquid crystal layer between a pair of substrates having electrodes, at least one of the substrates having a liquid crystal alignment film for vertically aligning liquid crystal, wherein the liquid crystal layer is obtained by disposing a liquid crystal composition containing a liquid crystal and a polymerizable compound between the pair of substrates and curing the liquid crystal composition by irradiating ultraviolet light to the liquid crystal composition by an ultraviolet light irradiation device, and the liquid crystal display element is suitably used as a converse-type element which exhibits a transmission state when no voltage is applied and a scattering state when a voltage is applied.

The liquid crystal composition of the present invention contains a liquid crystal and a polymerizable compound that is polymerized by ultraviolet rays and plays a role of forming a polymer network (curable resin). The liquid crystal layer is a cured product composite of a liquid crystal and a polymerizable compound, and the cured product composite herein refers to a state in which a liquid crystal is present in a polymer network formed of, for example, a polymerizable compound, as described above.

< specific Compound and liquid Crystal composition >

The liquid crystal composition of the present invention is a liquid crystal composition containing a liquid crystal, a polymerizable compound and a specific compound represented by the following formula [1 ].

The specific compound is a compound represented by the following formula [1 ].

Formula [1]In, X1、X2、X3、X4、X5、X6、X7、X8And p are as defined above, wherein each is preferably as follows.

From the viewpoint of optical characteristics of the liquid crystal display element, X1Preferably the aforementioned formula [1-a]Formula [1-b ]]Formula [1-c ]]Or formula [1-e]. More preferably of the formula [1-a]Formula [1-b ]]Or formula [1-c]。

From the viewpoints of availability of raw materials and ease of synthesis, X2Preferably a single bond, -O-, -CH2O-, -CONH-, -COO-or-OCO-. More preferably a single bond, -O-, -COO-or-OCO-. X3Preferably a single bond or- (CH)2)a- (a is an integer of 1 to 10). More preferably- (CH)2)a- (a is an integer of 1 to 10). From the viewpoints of availability of raw materials and ease of synthesis, X4Preferably a single bond, -O-or-COO-. More preferably-O-.

From the viewpoint of optical characteristics of the liquid crystal display element, X5Preferably a benzene ring, a cyclohexane ring, or a C17-51 organic group having a steroid skeleton. More preferably a benzene ring or a C17-51 2-valent organic group having a steroid skeleton. From the viewpoint of ease of synthesis, X6Preferably a single bond, -O-, -COO-or-OCO-. More preferably a single bond, -COO-or-OCO-.

From the viewpoint of optical characteristics of the liquid crystal display element, X7Preferably a benzene ring or a cyclohexane ring. From the viewpoint of optical characteristics of the liquid crystal display element, X8Preferably an alkyl group having 1 to 18 carbon atoms or an alkoxy group having 1 to 18 carbon atoms. More preferably an alkyl group having 1 to 12 carbon atoms. From the viewpoint of raw material availability and ease of synthesis, p is preferably an integer of 0 to 2.

Formula [1]X in (1)1~X8Preferred combinations with p are shown in tables 1 to 9 below.

[ Table 1]

[ Table 2]

[ Table 3]

[ Table 4]

[ Table 5]

[ Table 6]

[ Table 7]

[ Table 8]

[ Table 9]

Among them, from the viewpoint of optical characteristics of the liquid crystal display element, a combination of (1-1a) to (1-12a), (1-13a), (1-14a), (1-17a), (1-18a), (1-21a), (1-22a), (1-25a) to (1-38a), (1-41a), (1-42a), (1-45a), (1-46a), (1-49a) to (1-96a), or (1-121a) to (1-130a) is preferable.

More preferably a combination of (1-1a) - (1-4a), (1-9a), (1-12a), (1-25a) - (1-28a), (1-33a), (1-36a), (1-49a) - (1-52a), (1-61a) - (1-64a), (1-85a) - (1-88a), (1-121a), (1-122a), (1-125a) or (1-126 a).

Combinations of (1-3a), (1-4a), (1-9a), (1-10a), (1-27a), (1-28a), (1-33a), (1-34a), (1-49a) and (1-52a), (1-61a) and (1-64a), (1-85a) and (1-88a), (1-121a), (1-122a), (1-125a) and (1-126a) are particularly preferred.

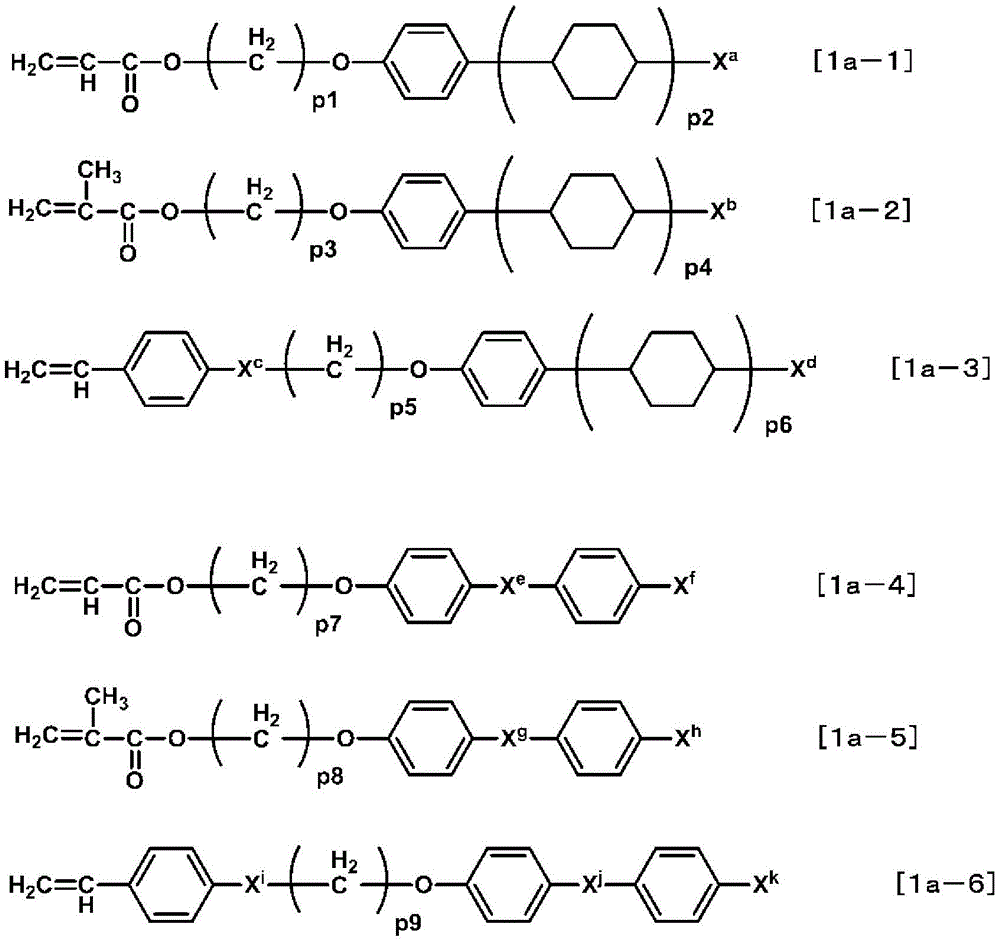

More specific compounds include compounds represented by the following formulae [1a-1] to [1a-6], and these compounds are preferably used.

Formula [1a-1]-formula [1a-6]In, Xa~XkAnd p1 to p9 are as defined above, and among them, the following are preferred.

From the viewpoint of optical characteristics of the liquid crystal display element, Xa、Xb、Xd、Xf、XhAnd XkEach independently preferably an alkyl group having 1 to 12 carbon atoms or an alkoxy group having 1 to 12 carbon atoms. More preferably an alkyl group having 1 to 8 carbon atoms or an alkoxy group having 1 to 8 carbon atoms. From the viewpoints of availability of raw materials and ease of synthesis, XcAnd XiEach independently is preferably-O-or-COO-. From the viewpoints of availability of raw materials and ease of synthesis, Xe、XgAnd XjEach independently is preferably-COO-or-OCO-. p1, p3, p5, p7, p8 and p9 are each independently preferably an integer of 1 to 10. From the viewpoint of optical characteristics of the liquid crystal display element, an integer of 1 to 8 is more preferable. p2, p4 and p6 are each independently preferably an integer of 1 or 2.

From the viewpoint of optical characteristics of the liquid crystal display element, the use ratio of the specific compound in the liquid crystal composition is preferably 0.1 to 20 parts by mass with respect to 100 parts by mass of the total of the liquid crystal and the polymerizable compound. More preferably 0.5 to 15 parts by mass, and particularly preferably 1 to 10 parts by mass.

These specific compounds may be used in 1 kind or 2 or more kinds in combination depending on the optical characteristics of the liquid crystal display element and the adhesion characteristics of the liquid crystal layer and the liquid crystal alignment film.

The liquid crystal in the liquid crystal composition may be nematic liquid crystal, smectic liquid crystal or cholesteric liquid crystal. Among them, it preferably has negative dielectric anisotropy. From the viewpoint of low-voltage driving and scattering characteristics, liquid crystals having a large anisotropy of dielectric constant and a large anisotropy of refractive index are preferable. Further, 2 or more kinds of liquid crystals may be mixed and used according to the respective physical property values of the phase transition temperature, the dielectric anisotropy and the refractive index anisotropy.

In order to drive a liquid crystal display element using an active element such as a TFT (Thin Film Transistor), the liquid crystal is required to have high resistance and high voltage holding ratio (also referred to as VHR). Therefore, fluorine-based or chlorine-based liquid crystals having high resistance and a VHR that is not lowered by active energy rays such as ultraviolet rays are preferably used as the liquid crystals.

Further, the liquid crystal display element may be a guest-host type element in which a dichroic dye is dissolved in a liquid crystal composition. In this case, an element which is transparent when no voltage is applied and which absorbs (scatters) when a voltage is applied can be obtained. In this liquid crystal display element, the direction of the director (alignment direction) of the liquid crystal changes by 90 degrees depending on whether or not a voltage is applied. Therefore, the liquid crystal display element can obtain a high contrast by utilizing the difference in light absorption characteristics of the dichromatic dye, as compared with the existing guest-host type element in which switching is performed by random alignment and vertical alignment. In the guest-host type element in which the dichroic dye is dissolved, the liquid crystal becomes colored when oriented in the horizontal direction, and becomes opaque only in the scattering state. Therefore, an element which switches from colorless transparency when no voltage is applied to a colored opaque state to colored transparent state with the application of a voltage can also be obtained.

The polymerizable compound in the liquid crystal composition may be a liquid crystal layer, which is a cured product composite (e.g., a polymer network) of the liquid crystal composition formed by polymerization reaction of ultraviolet rays. In this case, a monomer of a polymerizable compound may be introduced into the liquid crystal composition, or a polymer obtained by polymerizing the monomer in advance may be introduced into the liquid crystal composition. Among them, even when a polymer is produced, it is necessary to have a site where a polymerization reaction occurs by ultraviolet rays. From the viewpoint of handling of the liquid crystal composition, that is, suppression of an increase in viscosity of the liquid crystal composition and solubility in liquid crystal, a method of introducing a monomer into the liquid crystal composition and causing a polymerization reaction by ultraviolet irradiation at the time of producing a liquid crystal display element to form a cured product is more preferable.

The polymerizable compound is preferably a compound dissolved in a liquid crystal. Among them, when the polymerizable compound is dissolved in the liquid crystal, it is preferable that a temperature at which a part or the whole of the liquid crystal composition shows a liquid crystal phase is present. Preferably, even when a part of the liquid crystal composition exhibits a liquid crystal phase, the liquid crystal composition can be visually confirmed to have substantially uniform transparency and scattering characteristics throughout the liquid crystal cell.

The polymerizable compound may be any compound that undergoes a polymerization reaction by ultraviolet light, and in this case, any reaction form may be used to promote polymerization to form a cured product of the liquid crystal composition. Specific reaction forms include radical polymerization, cationic polymerization, anionic polymerization, and addition polymerization. Among them, radical polymerization is preferable. In this case, the following radical type polymerizable compounds (monomers) and oligomers thereof can be used as the polymerizable compound. Further, as described above, a polymer obtained by polymerizing these monomers may be used.

Examples of the monofunctional polymerizable compound (also referred to as a monofunctional monomer) include 2-ethylhexyl acrylate, butyl ethyl acrylate, butoxyethyl acrylate, 2-cyanoethyl acrylate, benzyl acrylate, cyclohexyl acrylate, hydroxyethyl acrylate, 2-hydroxypropyl acrylate, 2-ethoxyethyl acrylate, N-diethylaminoethyl acrylate, N-dimethylaminoethyl acrylate, dicyclopentyl acrylate, dicyclopentenyl acrylate, glycidyl acrylate, tetrahydrofurfuryl acrylate, isobornyl acrylate, isodecyl acrylate, lauryl acrylate, morpholino acrylate, phenoxyethyl acrylate, phenoxydiethylene glycol acrylate, 2,2, 2-trifluoroethyl acrylate, 2,2,3,3, 3-pentafluoropropyl acrylate, 2,3, 3-tetrafluoropropyl acrylate, 2,3,4,4, 4-hexafluorobutyl acrylate, 2-ethylhexyl methacrylate, butyl ethyl methacrylate, butoxyethyl methacrylate, 2-cyanoethyl methacrylate, benzyl methacrylate, cyclohexyl methacrylate, hydroxyethyl methacrylate, 2-hydroxypropyl methacrylate, 2-ethoxyethyl acrylate, N-diethylaminoethyl methacrylate, N-dimethylaminoethyl methacrylate, dicyclopentanyl methacrylate, dicyclopentenyl methacrylate, glycidyl methacrylate, tetrahydrofurfuryl methacrylate, isobornyl methacrylate, isodecyl methacrylate, lauryl methacrylate, and, Morpholine methacrylate (morpholino methacrylate), phenoxyethyl methacrylate, phenoxydiethylene glycol methacrylate, 2,2, 2-trifluoroethyl methacrylate, 2,2,3, 3-tetrafluoropropyl methacrylate, or 2,2,3,4, 4-hexafluorobutyl methacrylate, and oligomers thereof, and the like.

Examples of the bifunctional polymerizable compound (also referred to as a bifunctional monomer) include 4,4 ' -biphenyl diacrylate, diethylstilbestrol diacrylate, 1, 4-bisacryloxybenzene, 4 ' -bisacryloxydiphenyl ether, 4 ' -bisacryloxydiphenylmethane, 3,9- [1, 1-dimethyl-2-acryloyloxyethyl ] -2,4,8, 10-tetraoxaspiro [5,5] undecane, α ' -bis [ 4-acryloyloxyphenyl ] -1, 4-diisopropylbenzene, 1, 4-bisacryloxytetrafluorobenzene, 4 ' -bisacryloxytetrafluorobiphenyl, diethylene glycol acrylate, 1, 4-butanediol diacrylate, 1, 3-butanediol diacrylate, dicyclopentanyl diacrylate, glycerin diacrylate, 1, 6-hexanediol diacrylate, neopentyl glycol diacrylate, tetraethylene glycol diacrylate, 1, 9-nonanediol diacrylate, polyethylene glycol diacrylate, polypropylene glycol diacrylate, 1, 9-nonanediol dimethacrylate, polyethylene glycol dimethacrylate, polypropylene glycol dimethacrylate, and oligomers thereof.

Examples of the polyfunctional polymerizable compound (also referred to as a polyfunctional monomer) include trimethylolpropane triacrylate, pentaerythritol tetraacrylate, pentaerythritol triacrylate, ditrimethylolpropane tetraacrylate, dipentaerythritol hexaacrylate, dipentaerythritol monohydroxypentaacrylate, 4 '-diacryloyloxydiphenylene, 4' -diacryloyloxydimethylstyrene, 4 '-diacryloyloxydiethylstilbene, 4' -diacryloyloxydipropylstilbene, 4 '-diacryloyloxydibutylstilbene, 4' -diacryloyloxydiphenyloxydiphenylstilbene, 4, 4' -diacryloyloxydifluorodiphenylstyrene, 2,2,3,3,4, 4-hexafluoropentanediol-1, 5-diacrylate, 1,2,2,3, 3-hexafluoropropyl-1, 3-diacrylate, diethylene glycol dimethacrylate, 1, 4-butanediol dimethacrylate, 1, 3-butanediol dimethacrylate, 1, 6-hexanediol dimethacrylate, neopentyl glycol dimethacrylate, tetraethylene glycol dimethacrylate, trimethylolpropane trimethacrylate, pentaerythritol tetramethacrylate, pentaerythritol trimethacrylate, ditrimethylolpropane tetramethacrylate, dipentaerythritol hexamethacrylate, dipentaerythritol monohydroxypentamethacrylate or 2,2,3,3,4, 4-hexafluoropentanediol-1, 5-dimethacrylate, an oligomer thereof, and the like.

These radical type polymerizable compounds may be used in 1 kind or in a mixture of 2 or more kinds depending on the optical characteristics of the liquid crystal display element and the adhesion characteristics between the liquid crystal layer and the liquid crystal alignment film. In order to accelerate the formation of a cured product composite from the liquid crystal composition, it is preferable to introduce a radical initiator (also referred to as a polymerization initiator) that generates radicals by ultraviolet rays into the liquid crystal composition in order to accelerate radical polymerization of the polymerizable compound.

Examples thereof include tert-butyl peroxyisobutyrate, 2, 5-dimethyl-2, 5-bis (benzoyldioxy) hexane, 1, 4-bis [ alpha- (tert-butyldioxy) isopropoxy ] benzene, di-tert-butyl peroxide, 2, 5-dimethyl-2, 5-bis (tert-butyldioxy) hexylene peroxide, alpha- (isopropylphenyl) isopropyl peroxide, 2, 5-dimethylhexane, tert-butyl peroxide, 1-bis (tert-butyldioxy) -3,3, 5-trimethylcyclohexane, butyl-4, 4-bis (tert-butyldioxy) valerate, cyclohexanone peroxide, 2 ', 5, 5' -tetrakis (tert-butylperoxycarbonyl) benzophenone, 3 ', 4, 4' -tetrakis (tert-butylperoxycarbonyl) benzophenone, tert-butylperoxycarbonyl, Organic peroxides such as 3,3 ', 4, 4' -tetrakis (t-amylperoxycarbonyl) benzophenone, 3 ', 4, 4' -tetrakis (t-hexylperoxycarbonyl) benzophenone, 3 '-bis (t-butylperoxycarbonyl) -4, 4' -dicarboxybenzophenone, t-butyl peroxybenzoate, and di-t-butyl diperoxyiisophthalate; quinones such as 9, 10-anthraquinone, 1-chloroanthraquinone, 2-chloroanthraquinone, octamethylanthraquinone, and 1, 2-benzoanthraquinone; benzoin derivatives such as benzoin methyl ether, benzoin ethyl ether, α -methylbenzoin, and α -phenylbenzoin.

These radical initiators may be used in 1 kind or in combination of 2 or more kinds depending on the optical characteristics of the liquid crystal display element and the adhesion characteristics between the liquid crystal layer and the liquid crystal alignment film.

As the polymerizable compound, the following ionic polymerizable compounds can be used. Specifically, the compound has at least 1 kind of crosslinking-forming group selected from the group consisting of a hydroxyl group, a hydroxyalkyl group and a lower alkoxyalkyl group.

More specifically, examples of the crosslinkable compound having at least 1 group selected from the group consisting of a hydroxyl group, a hydroxyalkyl group and a lower alkoxyalkyl group include, specifically, melamine derivatives and benzoguanamine derivatives described on pages 39 to 40 of WO (international publication (kokai) No. WO) 2013/125595(2013.8.29 publication (the same shall apply hereinafter); a crosslinkable compound represented by the formulae [6-1] to [6-48] described in WO2011/132751 (published 2011.10.27) at pages 62 to 66.

Further, as the ionic polymerizable compound, a compound containing an epoxy group and an isocyanate group and having a crosslinking group may be used. Specifically, examples thereof include crosslinkable compounds having an epoxy group or an isocyanate group as described in WO2013/125595 (published 2013.8.29) on pages 37 to 38.

When an ionic polymerizable compound is used, an ionic initiator that generates an acid or a base by ultraviolet rays may be introduced to accelerate the polymerization reaction.

Specifically, for example, triazine compounds, acetophenone derivative compounds, disulfone compounds, diazomethane compounds, sulfonic acid derivative compounds, diaryliodonium salts, triarylsulfonium salts, triarylphosphonium salts, iron arene complexes, and the like can be used, but the present invention is not limited thereto. More specifically, there may be mentioned, for example, iodine diphenylchloride, iodine diphenyltrifluoromethanesulfonate, iodine diphenylmethanesulfonate, iodine diphenyltoluenesulfonate, iodine diphenylbromide, iodine diphenyltetrafluoroborate, iodine diphenylhexafluoroantimonate, iodine diphenylhexafluoroarsenate, iodine bis (p-tert-butylphenyl) hexafluorophosphate, iodine bis (p-tert-butylphenyl) methanesulfonate, iodine bis (p-tert-butylphenyl) toluenesulfonate, iodine bis (p-tert-butylphenyl) trifluoromethanesulfonate, iodine bis (p-tert-butylphenyl) tetrafluoroborate, iodine bis (p-tert-butylphenyl) chloride, iodine bis (p-chlorophenyl) tetrafluoroborate, triphenyl sulfonium chloride, triphenyl sulfonium bromide, sulfonium tris (p-methoxyphenyl) tetrafluoroborate, sulfonium tris (p-methoxyphenyl) hexafluorophosphate, sulfonium tris (p-ethoxyphenyl) tetrafluoroborate, triphenyl phosphonium chloride, iodine tris (p-chlorophenyl) tetrafluoroborate, triphenyl sulfonium chloride, Triphenyl phosphonium bromide, tris (p-methoxyphenyl) phosphonium tetrafluoroborate, tris (p-methoxyphenyl) phosphonium hexafluorophosphate, tris (p-ethoxyphenyl) phosphonium tetrafluoroborate, bis [ [ (2-nitrobenzyl) oxy ] carbonylhexane-1, 6-diamine ], nitrobenzylcyclohexylcyclohexane carbamate, bis (methoxybenzyl) hexamethylene dicarbamate, bis [ [ (2-nitrobenzyl) oxy ] carbonylhexane-1, 6-diamine ], nitrobenzylcyclohexane carbamate, or bis (methoxybenzyl) hexamethylene dicarbamate, and the like.

< specific side chain Structure >

The specific side chain structure of the present invention is represented by the following formula [2-1] or formula [2-2 ].

Formula [2-1]In, Y1、Y2、Y3、Y4、Y5、Y6And n are as defined above, wherein each is preferably as follows.

From the viewpoints of availability of raw materials and ease of synthesis, Y1Preferably a single bond, - (CH)2)a- (a is an integer of 1 to 15), -O-, -CH2O-or-COO-. More preferably a single bond, - (CH)2)a- (a is an integer of 1 to 10), -O-, -CH2O-or-COO-. Y is2Preferably a single bond or- (CH)2)b- (b is an integer of 1 to 10). From the viewpoint of ease of synthesis, Y3Preferably a single bond, - (CH)2)a- (a is an integer of 1 to 15), -O-, -CH2O-or-COO-. More preferably a single bond, - (CH)2)a- (a is an integer of 1 to 10), -O-, -CH2O-or-COO-. From the viewpoint of ease of synthesis, Y4Preferably a benzene ring, a cyclohexane ring, or an organic group having 17 to 51 carbon atoms and having a steroid skeleton.

Y5Preferably a benzene ring or a cyclohexane ring. Y is6Preferably an alkyl group having 1 to 18 carbon atoms, a fluorinated alkyl group having 1 to 10 carbon atoms, an alkoxy group having 1 to 18 carbon atoms or a fluorinated alkoxy group having 1 to 10 carbon atoms. More preferably an alkyl group having 1 to 12 carbon atoms or an alkoxy group having 1 to 12 carbon atoms. Particularly preferably an alkyl group having 1 to 9 carbon atoms or an alkoxy group having 1 to 9 carbon atoms. From the viewpoint of raw material availability and ease of synthesis, n is preferably 0 to 3, more preferably 0 to 2.

Y1~Y6Preferable combinations with n include the same combinations as (2-1) to (2-629) described in tables 6 to 47 on pages 13 to 34 of WO2011/132751 (disclosed in 2011.10.27). In the tables of International publication, Y of the present invention is shown1~Y6Shown as Y1-Y6, but Y1-Y6 are understood to be Y1~Y6. In addition, (2-605) to (2-629) described in each table of the international publication, the organic group having 17 to 51 carbon atoms of the steroid skeleton of the present invention is shown as an organic group having 12 to 25 carbon atoms of the steroid skeleton, but the organic group having 12 to 25 carbon atoms of the steroid skeleton can be understood as an organic group having 17 to 51 carbon atoms of the steroid skeleton.

Among them, preferred is a combination of (2-25) to (2-96), (2-145) to (2-168), (2-217) to (2-240), (2-268) to (2-315), (2-364) to (2-387), (2-436) to (2-483), (2-603) to (2-615), or (2-624). Particularly preferred combinations are (2-49) to (2-96), (2-145) to (2-168), (2-217) to (2-240), (2-603) to (2-606), (2-607) to (2-609), (2-611), (2-612), or (2-624).

-Y7-Y8[2-2]

Formula [2-2]]In, Y7And Y8As described above, the following are preferred.

Y7Preferably a single bond, -O-, -CH2O-、-CONH-、-CON(CH3) -or-COO-. More preferably a single bond, -O-, -CONH-or-COO-. Y is8Preferably an alkyl group having 8 to 18 carbon atoms.

As described above, the specific side chain structure of the present invention is preferably a specific side chain structure represented by the formula [2-1] from the viewpoint of obtaining a high and stable vertical alignment property of liquid crystal.

< specific Polymer >

The specific polymer having a specific side chain structure is not particularly limited, and is preferably at least 1 polymer selected from the group consisting of an acrylic polymer, a methacrylic polymer, a novolac resin, polyhydroxystyrene, a polyimide precursor, polyimide, polyamide, polyester, cellulose, and polysiloxane. More preferably a polyimide precursor, polyimide or polysiloxane.

When a polyimide precursor or a polyimide (also collectively referred to as a polyimide-based polymer) is used as the specific polymer, it is preferably a polyimide precursor or a polyimide obtained by reacting a diamine component with a tetracarboxylic acid component.

The polyimide precursor has a structure represented by the following formula [ A ].

(R1Represents a 4-valent organic group. R2Represents a 2-valent organic group. A. the1And A2Each independently represents a hydrogen atom or an alkyl group having 1 to 8 carbon atoms. A. the3And A4Each independently represents a hydrogen atom, an alkyl group having 1 to 5 carbon atoms or an acetyl group. n represents a positive integer. )

The diamine component may be a diamine having 2 primary or secondary amino groups in the molecule, and the tetracarboxylic acid component may be a tetracarboxylic acid compound, a tetracarboxylic acid dianhydride, a tetracarboxylic acid dihalide compound, a tetracarboxylic acid dialkyl ester compound, or a tetracarboxylic acid dialkyl ester dihalide compound.

The polyimide polymer is preferably a polyamic acid having a structural formula of a repeating unit represented by the following formula [ D ] or a polyimide obtained by imidizing the polyamic acid, because the polyimide polymer can be obtained relatively easily from a tetracarboxylic dianhydride represented by the following formula [ B ] and a diamine represented by the following formula [ C ].

(R1And R2And formula [ A]The meanings defined in (1) are the same. )

(R1And R2And formula [ A]The meanings defined in (1) are the same. )

Further, the formula [ D ] obtained as described above can also be synthesized by a usual synthesis method]Into the polymer of the formula [ A ]]Shown as A1And A2An alkyl group having 1 to 8 carbon atoms and the formula [ A]Shown as A3And A4An alkyl group or acetyl group having 1 to 5 carbon atoms.

As a method for introducing the specific side chain structure into the polyimide-based polymer, a diamine having a specific side chain structure is preferably used as a part of the raw material. Particularly, a diamine represented by the following formula [2a ] (also referred to as a specific side chain type diamine) is preferably used.

In the formula [2a ], Y represents a structure represented by the formula [2-1] or the formula [2-2 ].

Further, the formula [2-1]Y in (1)1、Y2、Y3、Y4、Y5、Y6And details and preferred combinations of n are as shown above, formula [2-2]Y in (1)7And Y8The details and preferred combinations of (a) are as indicated above.

m represents an integer of 1 to 4. Among them, an integer of 1 is preferable.

As having the formula [2-1]Specific examples of the specific side chain type diamine having the specific side chain structure include those described in WO2013/125595 (published 2013.8.29) on pages 15 to 19 and represented by the formula [2-1]]-formula [2-6]Is of the formula [2-9]-formula [2-36]The diamine compound of (1). In the description of WO2013/125595, the formula [2-1]]-formula [2-3]R in (1)2And formula [2-4 ]]-formula [2-6]R in (1)4Represents at least 1 selected from the group consisting of C1-18 alkyl, C1-18 fluorinated alkyl, C1-18 alkoxy and C1-18 fluorinated alkoxy. Furthermore, the formula [2-13]A in (A)4Represents a linear or branched alkyl group having 3 to 18 carbon atoms. And, formula [2-4 ]]-formula [2-6]R in (1)3Represents a group selected from-O-, -CH2At least 1 of the group consisting of O-, -COO-and-OCO-.

Among them, the diamine is preferably a diamine compound of the formula [2-1] to the formula [2-6], the formula [2-9] to the formula [2-13] or the formula [2-22] to the formula [2-31] described in WO 2013/125595.

Further, from the viewpoints of the vertical alignment properties of liquid crystals when the liquid crystal alignment film is formed and the optical characteristics of a liquid crystal display element, diamines represented by the following formulae [2a-32] to [2a-36] are most preferable.

(R1represents-CH2O-。R2Represents an alkyl group having 3 to 12 carbon atoms. )

(R3Represents an alkyl group having 3 to 12 carbon atoms, and cis-trans isomerization of a1, 4-cyclohexylidene group into a trans isomer. )

As having the aforementioned formula [2-2]Specific examples of the specific side chain type diamine having a specific side chain structure include those described in WO2013/125595 (published 2013.8.29) on page 23 of the formula [ DA 1]]-formula [ DA11]The diamine compound of (1). In the description of WO2013/125595, the formula [ DA 1]]-formula [ DA5]A in (A)1Represents an alkyl group having 8 to 22 carbon atoms or a fluoroalkyl group having 6 to 18 carbon atoms.

The proportion of the specific side chain diamine used is preferably 10 to 80 mol%, more preferably 20 to 70 mol%, based on the whole diamine component, from the viewpoints of the vertical alignment properties of liquid crystal when the liquid crystal alignment film is formed and the adhesion between the liquid crystal layer and the liquid crystal alignment film in the liquid crystal display element.

The specific side chain type diamine may be used in 1 kind or 2 or more kinds in combination depending on the solubility of the polyimide-based polymer in a solvent, the vertical alignment property of liquid crystal when a liquid crystal alignment film is formed, and the optical characteristics of a liquid crystal display element.

As the diamine component used for producing the polyimide-based polymer, a diamine represented by the following formula [2b ] (also referred to as a2 nd diamine) is preferably used.

T represents at least 1 substituent selected from the group consisting of structures represented by the following formulae [2-1b ] to [2-4b ]. r represents an integer of 1 to 4. Among them, an integer of 1 is preferable.

Formula [2-1b ]]Wherein a represents an integer of 0 to 4. Among them, an integer of 0 or 1 is preferable from the viewpoint of availability of raw materials and ease of synthesis. Formula [2-2b ]]Wherein b represents an integer of 0 to 4. Among them, an integer of 0 or 1 is preferable from the viewpoint of availability of raw materials and ease of synthesis. Formula [2-3b ]]In, T1And T2Independently represents a C1-12 hydrocarbon group. Formula [2-4b ]]In, T3Represents an alkyl group having 1 to 5 carbon atoms.

Specific structures of the 2 nd type diamines are listed below, but the diamines are not limited to these examples. Examples thereof include 2, 4-dimethyl-m-phenylenediamine, 2, 6-diaminotoluene, 2, 4-diaminophenol, 3, 5-diaminobenzyl alcohol, 2, 4-diaminobenzyl alcohol, 4, 6-diaminoresorcinol, 2, 4-diaminobenzoic acid, 2, 5-diaminobenzoic acid or 3, 5-diaminobenzoic acid, and diamines having structures represented by the following formulae [2b-1] to [2b-6 ].

Among them, preferred is 2, 4-diaminophenol, 3, 5-diaminobenzyl alcohol, 2, 4-diaminobenzyl alcohol, 4, 6-diaminoresorcinol, 2, 4-diaminobenzoic acid, 2, 5-diaminobenzoic acid, 3, 5-diaminobenzoic acid, a diamine represented by the formula [2b-1], the formula [2b-2] or the formula [2b-3 ]. Particularly preferred are diamines represented by the formula [2b-1] or the formula [2b-2], 2, 4-diaminophenol, 3, 5-diaminobenzyl alcohol, 3, 5-diaminobenzoic acid, and the like, from the viewpoints of solubility of a polyimide polymer in a solvent and optical characteristics of a liquid crystal display element.

The proportion of the 2 nd type diamine used is preferably 1 to 50 mol%, more preferably 1 to 40 mol%, and particularly preferably 5 to 40 mol% based on the whole diamine component, from the viewpoint of adhesion between a liquid crystal layer and a liquid crystal alignment film in a liquid crystal display element.

The 2 nd diamine may be used in 1 kind or 2 or more kinds in combination depending on the solubility of the polyimide polymer in a solvent, the vertical alignment property of liquid crystal when a liquid crystal alignment film is formed, and the optical characteristics of a liquid crystal display element.

As the diamine component used for producing the polyimide-based polymer, diamines other than the specific side chain type diamine and the 2 nd type diamine (also referred to as other diamines) may be used within a range not impairing the effect of the present invention.

Specifically, there may be mentioned other diamine compounds described on pages 19 to 23 of WO2013/125595 (published 2013.8.29), diamine compounds of the formulae [ DA12] and [ DA15] to [ DA20] described on page 24 of the publication, and diamine compounds of the formulae [ DA26] to [ DA28] described on pages 25 to 26 of the publication. Further, other diamines may be used in 1 kind or 2 or more kinds in combination depending on the characteristics.

The tetracarboxylic acid component used for producing the polyimide-based polymer is a tetracarboxylic dianhydride represented by the following formula [3] or a tetracarboxylic acid derivative thereof, and among them, a tetracarboxylic acid dihalide, a tetracarboxylic acid dialkyl ester or a tetracarboxylic acid dialkyl ester dihalide (all of which are also collectively referred to as a specific tetracarboxylic acid component) is preferable.

Z represents at least 1 structure selected from the group consisting of the following formulas [3a ] to [3k ].

In view of ease of synthesis and ease of polymerization in the production of a polymer, Z in the formula [3] is preferably represented by the formula [3a ], the formula [3c ], the formula [3d ], the formula [3e ], the formula [3f ], the formula [3g ] or the formula [3k ]. More preferably, the formula [3a ], the formula [3e ], the formula [3f ], the formula [3g ] or the formula [3k ], and particularly preferably the formula [3a ], the formula [3e ], the formula [3f ] or the formula [3g ] from the viewpoint of optical characteristics of the liquid crystal display element.

The proportion of the specific tetracarboxylic acid component to be used is preferably 1 mol% or more, more preferably 5 mol% or more, and still more preferably 10 mol% or more based on the total tetracarboxylic acid component. Among them, from the viewpoint of optical characteristics of the liquid crystal display element, 10 to 90 mol% is particularly preferable.

When the specific tetracarboxylic acid component of the above formula [3e ], formula [3f ], formula [3g ] or formula [3k ] is used, a desired effect can be obtained by using the specific tetracarboxylic acid component in an amount of 20 mol% or more based on the whole tetracarboxylic acid component. More preferably 30 mol% or more. Further, the tetracarboxylic acid component may be a tetracarboxylic acid component of the formula [3e ], the formula [3f ], the formula [3g ] or the formula [3k ].

The polyimide-based polymer may contain a tetracarboxylic acid component other than the specific tetracarboxylic acid component within a range not impairing the effects of the present invention. Examples of the other tetracarboxylic acid component include tetracarboxylic acids, tetracarboxylic dianhydrides, dicarboxylic acid dihalides, dialkyl dicarboxylates, or dialkyl ester dihalides shown below.

Specifically, there may be mentioned other tetracarboxylic acid components described on pages 27 to 28 of WO2013/125595 (published 2013.8.29). The specific tetracarboxylic acid component and the other tetracarboxylic acid components may be used in 1 kind or in a mixture of 2 or more kinds depending on the characteristics.

The method for synthesizing the polyimide-based polymer is not particularly limited. Usually, the diamine component is reacted with a tetracarboxylic acid component. Specifically, the method described on pages 29 to 30 of WO2013/125595 (published 2013.8.29) is included.

The reaction of the diamine component and the tetracarboxylic acid component is usually carried out in a solvent containing the diamine component and the tetracarboxylic acid component. The solvent used in this case is not particularly limited as long as the polyimide precursor formed is dissolved.

Examples thereof include N-methyl-2-pyrrolidone, N-ethyl-2-pyrrolidone, γ -butyrolactone, N-dimethylformamide, N-dimethylacetamide, dimethylsulfoxide, and 1, 3-dimethyl-imidazolidinone. When the polyimide precursor has high solubility in the solvent, a solvent represented by methyl ethyl ketone, cyclohexanone, cyclopentanone, 4-hydroxy-4-methyl-2-pentanone, or a solvent represented by the following formulae [ D-1] to [ D-3] can be used.

(D1Represents an alkyl group having 1 to 3 carbon atoms. D2Represents an alkyl group having 1 to 3 carbon atoms. D3Represents an alkyl group having 1 to 4 carbon atoms. )

They may be used alone or in combination. Further, even if the solvent does not dissolve the polyimide precursor, the solvent may be mixed and used within a range where the produced polyimide precursor is not precipitated. Further, the organic solvent is preferably dehydrated and dried for use because moisture in the organic solvent inhibits the polymerization reaction and causes hydrolysis of the polyimide precursor to be produced.

The molecular weight of the polyimide-based polymer is preferably 5,000 to 1,000,000, more preferably 10,000 to 150,000, in terms of the strength of the liquid crystal alignment film obtained therefrom, the workability in forming the liquid crystal alignment film, and the film coatability, as measured by GPC (Gel permeation chromatography).

When a polysiloxane is used as the specific polymer, it is preferably: a polysiloxane obtained by condensation polymerization of an alkoxysilane represented by the following formula [ A1 ]; alternatively, a polysiloxane (also collectively referred to as a polysiloxane polymer) obtained by polycondensing the alkoxysilane represented by the formula [ a1] with the alkoxysilane represented by the formula [ a2] and/or the alkoxysilane represented by the formula [ A3 ].

An alkoxysilane of the formula [ A1 ]:

(A1)mSi(A2)n(OA3)p[A1]

formula [ A1]In (A)1Represents the aforementioned formula [2-1]Or formula [2-2]The structure shown. Further, the formula [2-1]Y in (1)1、Y2、Y3、Y4、Y5、Y6And details and preferred combinations of n are as described above, formula [2-2]Y in (1)7And Y8The details and preferred combinations of (a) are as described above.

In the present invention, from the viewpoints of the vertical alignment properties of liquid crystals when the liquid crystal alignment film is formed and the optical characteristics of the liquid crystal display element, a1Preferably of the formula [2-1]The specific side chain structure shown.

Formula [ A1]In (A)2、A3M, n and p are as defined above. Among them, the following are preferred. A. the2Preferably a hydrogen atom or an alkyl group having 1 to 3 carbon atoms. From the viewpoint of polycondensation reactivity, A3Preferably an alkyl group having 1 to 3 carbon atoms. From the viewpoint of synthesis, m is preferably an integer of 1. n represents an integer of 0 to 2. From the viewpoint of polycondensation reactivity, p is preferably an integer of 1 to 3, more preferably an integer of 2 or 3. m + n + p is an integer of 4.

As having the formula [2-1]Specific examples of the alkoxysilane having a specific side chain structure include those described in WO2014/061779 (published 2014.4.24) on pages 41 to 44 [ A1-1]-formula [ A1-22]And formula [ A1-25]-formula [ A1-32]The alkoxysilane of (4). In the description of WO2014/061779, the formula [ A1-19 ] is]-formula [ A1-22]And formula [ A1-25]-formula [ A1-31]R in (1)2Represents a group selected from-O-, -CH2At least 1 of the group consisting of O-, -COO-and-OCO-.

Among them, the alkoxysilane is preferably represented by the formula [ A1-9] to the formula [ A1-21], the formula [ A1-25] to the formula [ A1-28] or the formula [ A1-32] described in WO2014/061779, from the viewpoints of the vertical alignment of a liquid crystal when a liquid crystal alignment film is formed and the optical characteristics of a liquid crystal display element.

The alkoxysilane represented by the formula [ a1] may be used in 1 kind or in a mixture of 2 or more kinds depending on the solubility of the polysiloxane polymer in a solvent, the vertical alignment property of liquid crystal when a liquid crystal alignment film is formed, and the optical characteristics of a liquid crystal display element.

An alkoxysilane of the formula [ A2 ]:

(B1)mSi(B2)n(OB3)p[A2]

formula [ A2]In (B)1、B2、B3M, n and p are as defined above. Wherein, each is superiorThe following were selected. From the viewpoint of ease of acquisition, B1Organic groups having a vinyl group, an epoxy group, an amino group, a methacryloyl group, an acryloyl group, or a ureido group are preferable. More preferably an organic group having a methacryloyl group, an acryloyl group or a ureido group. B is2Preferably a hydrogen atom or an alkyl group having 1 to 3 carbon atoms.

From the viewpoint of polycondensation reactivity, B3Preferably an alkyl group having 1 to 3 carbon atoms. From the viewpoint of synthesis, m is preferably an integer of 1. n represents an integer of 0 to 2. From the viewpoint of polycondensation reactivity, p is preferably an integer of 1 to 3, more preferably an integer of 2 or 3. m + n + p is 4.

Specific examples of the alkoxysilane represented by the formula [ A2] include alkoxysilanes represented by the formula [ A2] described on pages 45 to 46 of WO2014/061779 (published under 2014.4.24).

Among them, preferred is allyltriethoxysilane, allyltrimethoxysilane, diethoxymethylvinylsilane, dimethoxymethylvinylsilane, triethoxyvinylsilane, vinyltrimethoxysilane, vinyltris (2-methoxyethoxy) silane, 3- (triethoxysilyl) propyl methacrylate, 3- (trimethoxysilyl) propyl acrylate, 3- (trimethoxysilyl) propyl methacrylate, 3- (trimethoxysilyl) propyl 3-glycidoxypropyl (dimethoxy) methylsilane, 3-glycidoxypropyl (diethoxy) methylsilane, 3-glycidoxypropyltrimethoxysilane or 2- (3, 4-epoxycyclohexyl) ethyltrimethoxysilane.

From the viewpoint of adhesion between the liquid crystal layer of the liquid crystal display element and the liquid crystal alignment film, 3- (triethoxysilyl) propyl methacrylate, 3- (trimethoxysilyl) propyl acrylate, 3- (trimethoxysilyl) propyl methacrylate, 3-glycidoxypropyl (dimethoxy) methylsilane, 3-glycidoxypropyl (diethoxy) methylsilane, 3-glycidoxypropyltrimethoxysilane, or 2- (3, 4-epoxycyclohexyl) ethyltrimethoxysilane is particularly preferable. The alkoxysilane represented by the formula [ A2] may be used in 1 kind or in combination of 2 or more kinds.

An alkoxysilane of the formula [ A3 ]:

(D1)nSi(OD2)4-n[A3]

formula [ A3]In (D)1、D2And n are as defined above, wherein each is preferably as follows. D1Preferably a hydrogen atom or an alkyl group having 1 to 3 carbon atoms. From the viewpoint of polycondensation reactivity, D2Preferably an alkyl group having 1 to 3 carbon atoms. n represents an integer of 0 to 3.

Specific examples of the alkoxysilane represented by the formula [ A3] include alkoxysilanes represented by the formula [ A3] described on page 47 of WO2014/061779 (published as 2014.4.24).

Examples of the alkoxysilane in which n is 0 in the formula [ A3] include tetramethoxysilane, tetraethoxysilane, tetrapropoxysilane and tetrabutoxysilane. As the alkoxysilane of the formula [ A3], it is preferable to use these alkoxysilanes. The alkoxysilane represented by the formula [ A3] may be used in 1 kind or in combination of 2 or more kinds.

The polysiloxane polymer is a polysiloxane obtained by polycondensing an alkoxysilane represented by the formula [ A1] or a polysiloxane obtained by polycondensing an alkoxysilane represented by the formula [ A1] with an alkoxysilane represented by the formula [ A2] and/or an alkoxysilane represented by the formula [ A3 ]. That is, the polysiloxane polymer is any one of the following polysiloxanes: a polysiloxane obtained by condensation-polymerizing only an alkoxysilane represented by the formula [ A1 ]; polysiloxane obtained by condensation polymerization of 2 kinds of alkoxysilane represented by the formula [ A1] and the formula [ A2 ]; polysiloxane obtained by condensation polymerization of 2 kinds of alkoxysilane represented by the formula [ A1] and the formula [ A3 ]; and a polysiloxane obtained by condensation polymerization of 3 kinds of alkoxysilanes represented by the formulae [ A1], [ A2] and [ A3 ].

Among these, from the viewpoint of the polycondensation reactivity and the solubility of the polysiloxane polymer in a solvent, a polysiloxane obtained by polycondensing a plurality of alkoxysilanes is preferable. That is, any of the following polysiloxanes is preferably used: polysiloxane obtained by condensation polymerization of 2 kinds of alkoxysilane represented by the formula [ A1] and the formula [ A2 ]; polysiloxane obtained by condensation polymerization of 2 kinds of alkoxysilane represented by the formula [ A1] and the formula [ A3 ]; and a polysiloxane obtained by condensation polymerization of 3 kinds of alkoxysilanes represented by the formulae [ A1], [ A2] and [ A3 ].

When a plurality of alkoxysilanes are used in the preparation of the polysiloxane polymer, the ratio of the alkoxysilane represented by the formula [ a1] to be used is preferably 1 to 40 mol%, more preferably 1 to 30 mol%, based on the total amount of the alkoxysilanes. The ratio of the alkoxysilane represented by the formula [ A2] is preferably 1 to 70 mol%, more preferably 1 to 60 mol% based on the total amount of the alkoxysilanes. Further, the ratio of the alkoxysilane represented by the formula [ A3] is preferably 1 to 99 mol%, more preferably 1 to 80 mol%, based on the total amount of the alkoxysilanes.

The method of polycondensation reaction for producing the polysiloxane polymer is not particularly limited. Specifically, the method described on pages 49 to 52 of WO2014/061779 (published 2014.4.24) can be mentioned.

In the polycondensation reaction for producing the polysiloxane polymer, when a plurality of kinds of alkoxysilanes represented by the formula [ A1], the formula [ A2] or the formula [ A3] are used, a mixture in which a plurality of kinds of alkoxysilanes are mixed in advance may be used for the reaction, or the reaction may be carried out while a plurality of kinds of alkoxysilanes are added in order.

In the present invention, the solution of the polysiloxane polymer obtained by the above-mentioned method may be used as it is as the specific polymer, or the solution of the polysiloxane polymer obtained by the above-mentioned method may be concentrated, diluted by adding a solvent, or replaced with another solvent, if necessary, to be used as the specific polymer.

The solvent (also referred to as an additive solvent) used for dilution may be a solvent used for the polycondensation reaction or another solvent. The solvent to be added is not particularly limited as long as it uniformly dissolves the polysiloxane polymer, and 1 or 2 or more kinds thereof can be selected and used. Examples of the solvent to be added include, in addition to the solvent used in the above polycondensation reaction, ketone solvents such as acetone, methyl ethyl ketone, and methyl isobutyl ketone; ester solvents such as methyl acetate, ethyl acetate, and ethyl lactate. Further, when the polysiloxane polymer and other polymers are used as the specific polymer, it is preferable that the alcohol generated in the polycondensation reaction of the polysiloxane polymer is distilled off under normal pressure or reduced pressure in advance before the other polymers are mixed with the polysiloxane polymer.

< liquid Crystal alignment treating agent >

The liquid crystal alignment treatment agent is a solution for forming a liquid crystal alignment film, and contains a solvent and a specific polymer having a specific side chain structure of the aforementioned formula [2-1] or formula [2-2 ].

The specific polymer is not particularly limited as described above, and is preferably at least 1 polymer selected from the group consisting of acrylic polymers, methacrylic polymers, novolac resins, polyhydroxystyrene, polyimide precursors, polyimide, polyamide, polyester, cellulose, and polysiloxane. More preferably a polyimide precursor, polyimide or polysiloxane. Further, 1 or 2 or more of these polymers may be used as the specific polymer.

All of the polymer components in the liquid crystal aligning agent may be a specific polymer, or other polymers may be mixed. In this case, the content of the other polymer is 0.5 to 15 parts by mass, preferably 1 to 10 parts by mass, based on 100 parts by mass of the specific polymer. Examples of the other polymers include the polymers described above which do not have a specific side chain structure represented by the formula [2-1] or the formula [2-2 ].

The content of the solvent in the liquid crystal aligning agent can be appropriately selected from the viewpoint of the method of applying the liquid crystal aligning agent and obtaining a desired film thickness. Among them, the solvent content in the liquid crystal alignment treatment agent is preferably 50 to 99.9% by mass, more preferably 60 to 99% by mass, from the viewpoint of forming a uniform liquid crystal alignment film by coating. Particularly preferably 65 to 99 mass%.

The solvent used for the liquid crystal aligning agent is not particularly limited as long as it dissolves the specific polymer. Among them, when the specific polymer is a polyimide precursor, polyimide, polyamide or polyester, or when the solubility of an acrylic polymer, methacrylic polymer, novolac resin, polyhydroxystyrene, cellulose or polysiloxane in a solvent is low, it is preferable to use the solvent (also referred to as solvent a).

Examples thereof include N, N-dimethylformamide, N-dimethylacetamide, N-methyl-2-pyrrolidone, N-ethyl-2-pyrrolidone, dimethyl sulfoxide, γ -butyrolactone, 1, 3-dimethyl-imidazolidinone, methyl ethyl ketone, cyclohexanone, cyclopentanone, and 4-hydroxy-4-methyl-2-pentanone. Among them, N-methyl-2-pyrrolidone, N-ethyl-2-pyrrolidone or γ -butyrolactone is preferably used. Further, they may be used alone or in combination.

When the specific polymer is an acrylic polymer, a methacrylic polymer, a novolac resin, polyhydroxystyrene, cellulose, or polysiloxane, and further when the specific polymer is a polyimide precursor, polyimide, polyamide, or polyester and the solubility of the specific polymer in a solvent is high, the following solvents (also referred to as solvents B.) can be used.

Specific examples of the solvent B include poor solvents described on pages 35 to 37 of WO2013/125595 (published 2013.8.29).

Among them, 1-hexanol, cyclohexanol, 1, 2-ethylene glycol, 1, 2-propylene glycol, propylene glycol monobutyl ether, ethylene glycol monobutyl ether, dipropylene glycol dimethyl ether, cyclohexanone, cyclopentanone, or a solvent represented by the above-described formulae [ D1] to [ D3] is preferably used.

When these solvents B are used, it is preferable to use N-methyl-2-pyrrolidone, N-ethyl-2-pyrrolidone or γ -butyrolactone of the above solvents A in combination in order to improve the coatability of the liquid crystal alignment treatment agent. More preferably, gamma-butyrolactone is used in combination.

These solvents B can improve the film coatability and surface smoothness of the liquid crystal alignment film when the liquid crystal alignment treatment agent is applied, and therefore, when a polyimide precursor, a polyimide, a polyamide or a polyester is used as the specific polymer, it is preferable to use them in combination with the above-mentioned solvents a. In this case, the solvent B is preferably 1 to 99% by mass of the entire solvent contained in the liquid crystal aligning agent. Among them, it is preferably 10 to 99% by mass. More preferably 20 to 95 mass%.

In the present invention, at least 1 kind of generating agent (also referred to as a specific generating agent) selected from the group consisting of a photoradical generating agent, a photoacid generator, and a photobase generating agent is preferably introduced into the liquid crystal alignment treatment agent. Among them, the specific generator is preferably a photo radical generator from the viewpoint of adhesion between the liquid crystal layer and the liquid crystal alignment film.

The photo radical generator is not particularly limited as long as it generates radicals by ultraviolet rays. Examples thereof include tert-butyl peroxyisobutyrate, 2, 5-dimethyl-2, 5-bis (benzoyldioxy) hexane, 1, 4-bis [ alpha- (tert-butyldioxy) isopropoxy ] benzene, di-tert-butyl peroxide, 2, 5-dimethyl-2, 5-bis (tert-butyldioxy) hexylene peroxide, alpha- (isopropylphenyl) isopropyl peroxide, 2, 5-dimethylhexane, tert-butyl peroxide, 1-bis (tert-butyldioxy) -3,3, 5-trimethylcyclohexane, butyl-4, 4-bis (tert-butyldioxy) valerate, cyclohexanone peroxide, 2 ', 5, 5' -tetrakis (tert-butylperoxycarbonyl) benzophenone, 3 ', 4, 4' -tetrakis (tert-butylperoxycarbonyl) benzophenone, tert-butylperoxycarbonyl, Organic peroxides such as 3,3 ', 4, 4' -tetrakis (t-amylperoxycarbonyl) benzophenone, 3 ', 4, 4' -tetrakis (t-hexylperoxycarbonyl) benzophenone, 3 '-bis (t-butylperoxycarbonyl) -4, 4' -dicarboxybenzophenone, t-butyl peroxybenzoate, and di-t-butyl diperoxyiisophthalate; quinones such as 9, 10-anthraquinone, 1-chloroanthraquinone, 2-chloroanthraquinone, octamethylanthraquinone, and 1, 2-benzoanthraquinone; benzoin derivatives such as benzoin methyl ether, benzoin ethyl ether, α -methylbenzoin, and α -phenylbenzoin.

The photoacid generator and the photobase generator are not particularly limited as long as they generate an acid or a base by ultraviolet rays, and examples thereof include triazine compounds, acetophenone derivative compounds, disulfone compounds, diazomethane compounds, sulfonic acid derivative compounds, diaryliodonium salts, triarylsulfonium salts, triarylphosphonium salts, and iron arene complexes. More specifically, there may be mentioned, for example, iodine diphenylchloride, iodine diphenyltrifluoromethanesulfonate, iodine diphenylmethanesulfonate, iodine diphenyltoluenesulfonate, iodine diphenylbromide, iodine diphenyltetrafluoroborate, iodine diphenylhexafluoroantimonate, iodine diphenylhexafluoroarsenate, iodine bis (p-tert-butylphenyl) hexafluorophosphate, iodine bis (p-tert-butylphenyl) methanesulfonate, iodine bis (p-tert-butylphenyl) toluenesulfonate, iodine bis (p-tert-butylphenyl) trifluoromethanesulfonate, iodine bis (p-tert-butylphenyl) tetrafluoroborate, iodine bis (p-tert-butylphenyl) chloride, iodine bis (p-chlorophenyl) tetrafluoroborate, triphenyl sulfonium chloride, triphenyl sulfonium bromide, sulfonium tris (p-methoxyphenyl) tetrafluoroborate, sulfonium tris (p-methoxyphenyl) hexafluorophosphate, sulfonium tris (p-ethoxyphenyl) tetrafluoroborate, triphenyl phosphonium chloride, iodine tris (p-chlorophenyl) tetrafluoroborate, triphenyl sulfonium chloride, Triphenyl phosphonium bromide, tris (p-methoxyphenyl) phosphonium tetrafluoroborate, tris (p-methoxyphenyl) phosphonium hexafluorophosphate, tris (p-ethoxyphenyl) phosphonium tetrafluoroborate, bis [ [ (2-nitrobenzyl) oxy ] carbonylhexane-1, 6-diamine ], nitrobenzylcyclohexylcyclohexane carbamate, bis (methoxybenzyl) hexamethylene dicarbamate, bis [ [ (2-nitrobenzyl) oxy ] carbonylhexane-1, 6-diamine ], nitrobenzylcyclohexane carbamate, or bis (methoxybenzyl) hexamethylene dicarbamate, and the like.

In order to improve the adhesion between the liquid crystal layer and the liquid crystal alignment film, the liquid crystal alignment agent of the present invention preferably contains a compound having at least 1 structure selected from the group consisting of the following formulas [ b-1] to [ b-8] (also referred to as a specific adhesion compound).

Formula [ b-4]In (B)aRepresents a hydrogen atom or a benzene ring. Among them, a hydrogen atom is preferable. Formula [ b-8]In (B)bRepresents at least 1 cyclic group selected from the group consisting of a benzene ring, a cyclohexane ring and a heterocyclic ring. B iscRepresents at least 1 kind selected from the group consisting of alkyl, fluorine-containing alkyl, alkoxy and fluorine-containing alkoxy with 1-18 carbon atoms. Among them, preferred is an alkyl group or an alkoxy group having 1 to 12 carbon atoms.

More specifically, the specific adhesion compound is preferably a compound represented by the following formula [7A ].

Formula [7A ]]In, M1Is represented by a formula [ a-1] selected from]~[a-7]At least 1 of the group consisting of. Among them, the formula [ a-1] is preferred from the viewpoint of ease of production]Is of the formula [ a-2]Is of the formula [ a-3]Is of the formula [ a-5]Or formula [ a-6]. More preferably of the formula [ a-1]Is of the formula [ a-3]Is of the formula [ a-5]Or formula [ a-6]。

A1Represents a hydrogen atom or an alkyl group having 1 to 5 carbon atoms. Among them, from the viewpoint of ease of production, a hydrogen atom or an alkyl group having 1 to 2 carbon atoms is preferable. More preferably a hydrogen atom or a methyl group.

A2Represents a hydrogen atom or an alkyl group having 1 to 3 carbon atoms. Among them, from the viewpoint of ease of production, a hydrogen atom or an alkyl group having 1 to 2 carbon atoms is preferable. More preferably a hydrogen atom or a methyl group.

A3、A5、A6And A9Independently represents a hydrogen atom or an alkyl group having 1 to 3 carbon atoms. Among them, from the viewpoint of ease of production, a hydrogen atom or an alkyl group having 1 to 2 carbon atoms is preferable. More preferably a hydrogen atom or a methyl group.

A4、A7And A8Independently represents an alkylene group having 1 to 3 carbon atoms. Among them, an alkylene group having 1 to 2 carbon atoms is preferable from the viewpoint of ease of production.

Formula [7A ]]In, M2Is selected from the group consisting of a single bond, -CH2-、-O-、-NH-、-N(CH3)-、-CONH-、-NHCO-、-CH2O-、-OCH2-、-COO-、-OCO-、-CON(CH3) -and-N (CH)3) At least 1 bonding group of the group consisting of CO-. Among them, a single bond, -CH is preferable from the viewpoint of ease of production2-、-O-、-NH-、-CONH-、-NHCO-、-CH2O-、-OCH2-、-COO-、-OCO-、-CON(CH3) -or-N (CH)3) CO-. More preferably a single bond, -CH2-、-O-、-NH-、-CONH-、-CH2O-、-OCH2-, -COO-or-OCO-. In particularPreferably a single bond, -O-, -CONH-, -OCH2-, -COO-or-OCO-.