CN103668477A - Suction nozzle sucking ginned cotton - Google Patents

Suction nozzle sucking ginned cotton Download PDFInfo

- Publication number

- CN103668477A CN103668477A CN201310663397.8A CN201310663397A CN103668477A CN 103668477 A CN103668477 A CN 103668477A CN 201310663397 A CN201310663397 A CN 201310663397A CN 103668477 A CN103668477 A CN 103668477A

- Authority

- CN

- China

- Prior art keywords

- gettering container

- suction nozzle

- gined cotton

- suction box

- air suction

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Compressors, Vaccum Pumps And Other Relevant Systems (AREA)

Abstract

The invention relates to a suction nozzle sucking ginned cotton. The suction nozzle comprises an air suction box with the trapezoidal section, the upper side of the air suction box is narrow, the lower side of the air suction box is wide, the wide end of the air suction box is an inlet, the narrow end of the air suction box is an outlet, the outlet of the air suction box is provided with a conveying pipe communicated with the air suction box, and each wall of the air suction box is provided with a plurality of balls capable of rotating. According to the suction nozzle sucking the ginned cotton, the inner walls of the air suction box are evenly provided with the balls capable of rotating, the rotating balls can exert pushing force on the ginned cotton towards the outlet, resistance to the ginned cotton from the inner walls of the air suction box is eliminated, and air exhaust resistance is greatly reduced. Meanwhile, the ginned cotton can not generate an eddy on the rotating balls, and the air exhaust resistance is further reduced.

Description

Technical field

The present invention relates to a kind of textile apparatus, relate in particular to a kind of for drawing the suction nozzle of the cotton fiber brushing down through sawtooth cotton gin.

Background technology

Gined cotton after the gined cotton that sawtooth cotton gin shuts out or lint cotton cleaner cleaning is conventionally sent to baling press by compacting devices and packs, the effect of compacting devices is to utilize the collection web of rotation that the gentle flow point of gined cotton is opened, make loose cotton fiber be gathered in collection web surface and be pressed into cotton sheet, then be sent to baling press packing.Compacting devices need to utilize air-flow that the gined cotton of cotton gin production is collected and is sent to collection hopper, conventionally utilizes air-breathing mode to draw gined cotton, utilizes blower fan, by suction nozzle, gined cotton is drawn into collection hopper.Existing suction nozzle is triangle box-shaped or flat air channel shape, and gined cotton easily produces eddy current in the suction nozzle of triangle box-shaped or flat air channel shape, and gined cotton and suction nozzle inwall can produce larger friction, have increased exhaust resistance, be unfavorable for collecting web gined cotton is pressed into cotton sheet.

Summary of the invention

The present invention has overcome the deficiencies in the prior art, and a kind of gined cotton suction nozzle simple in structure is provided, and to avoid gined cotton to produce eddy current in suction nozzle, reduces the friction of gined cotton and suction nozzle inwall, to reduce exhaust resistance.

For achieving the above object, the technical solution used in the present invention is: a kind of suction nozzle of drawing gined cotton, it is characterized in that: comprise that cross section is trapezoidal up-narrow and down-wide gettering container, the wider one end of described gettering container is suction inlet, narrower one end is outlet, the exit of described gettering container is provided with the carrier pipe being communicated with described gettering container, is equipped with several rotating balls on each inwall of described gettering container.

In a preferred embodiment of the present invention, further comprise that described ball is evenly covered with each inwall of described gettering container, the sandwich that described gettering container shell is hollow, described gettering container inwall is provided with several circular holes that can rotate for described ball, in the shell of described gettering container hollow, be laterally provided with some row's back shafts, described ball is inserted in described circular hole and part exposes to described circular hole and is applied in successively on described back shaft.

In a preferred embodiment of the present invention, further comprise that the area of cross section of described carrier pipe and the area of the outlet of described gettering container equate.

In a preferred embodiment of the present invention, the angle that further comprises the suction inlet of described gettering container and the sidewall of described gettering container is 40 °~60 °.

In a preferred embodiment of the present invention, further comprise seamless contact between described ball and described circular hole.

In a preferred embodiment of the present invention, further comprise that described ball made by stainless steel.

In a preferred embodiment of the present invention, the angle that further comprises the suction inlet of described gettering container and the sidewall of described gettering container is 55 °.

The invention solves the defect existing in background technology, the suction nozzle of absorption gined cotton of the present invention is by being evenly covered with rotating ball at gettering container inwall, the ball rotating can give gined cotton the thrust to outlet, eliminated the resistance of gettering container inwall to gined cotton, greatly reduced exhaust resistance, meanwhile, gined cotton can not produce eddy current on the ball rotating, and further reduces exhaust resistance.

Accompanying drawing explanation

Below in conjunction with drawings and Examples, the present invention is further described.

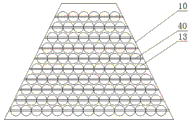

Fig. 1 is the structural representation of the preferred embodiments of the present invention;

Fig. 2 be in figure A-A to view;

In figure: 10, gettering container, 11, suction inlet, 12, outlet, 13, circular hole, 20, carrier pipe, 30, ball, 40, back shaft.

The specific embodiment

The present invention is further detailed explanation in conjunction with the accompanying drawings and embodiments now, and these accompanying drawings are the schematic diagram of simplification, basic structure of the present invention is only described in a schematic way, so it only shows the formation relevant with the present invention.

As depicted in figs. 1 and 2, a kind of suction nozzle of drawing gined cotton, comprise that cross section is trapezoidal up-narrow and down-wide gettering container 10, the wider one end of gettering container 10 is suction inlet 11, narrower one end is outlet 12, outlet 12 places of gettering container 10 are provided with the carrier pipe 20 being communicated with gettering container 10, are equipped with several rotating balls 30 on gettering container 10 each inwalls.Ball 30 is evenly covered with gettering container 10 each inwalls, concrete, gettering container 10 shells are set to the sandwich of hollow, at gettering container 10 inwalls, be provided with the circular hole 13 that several can rotate for ball 30, the some row's back shafts 40 of horizontally set in the shell of gettering container 10 hollows, insert in circular hole 13 by ball 30 and part exposes to circular hole 13 and is applied in successively on back shaft 40.By rotating ball 30 is set on gettering container 10 inwalls, ball 30 is under the effect of blower fan suction, can rotate, gined cotton sucks through gettering container 10, the ball 30 rotating can be to thrust to outlet 12 of gined cotton, and the resistance that does not exist gettering container 10 inwalls to produce gined cotton has reduced exhaust resistance greatly; In addition, gined cotton is in the interior transmitting procedure of gettering container 10, and ball 30 ceaselessly rotates towards outlet 12 directions, and gined cotton contacts the situation that can not produce eddy current with the ball 30 of rotation.

Further, the area of the cross section of carrier pipe 20 equates with the area of the outlet 12 of gettering container 10, guarantees that gined cotton can not deposit at outlet 12 places, makes gined cotton transmission unimpeded.

Further, the suction inlet 11 of gettering container 10 is 40 °~60 ° with the angle of the sidewall of gettering container 10, preferably, suction inlet 11 that can gettering container 10 is set to 55 ° with the angle of the sidewall of gettering container 10, further avoid air-flow in suction nozzle, to produce eddy current, further reduce the frictional impact of cotton fiber and gettering container 10 inwalls.

Further, ball 30 is made by stainless steel, with seamless contact between circular hole 13, ball 30 smooth surfaces that stainless steel is made, and the friction between circular hole 13 is less, be convenient to ball 30 and rotate, and seamless contact between ball 30 and circular hole 13, avoid the cotton fiber of gined cotton to enter in circular hole 13 and affect ball 30 rotations.

The beneficial effect of the suction nozzle of absorption gined cotton of the present invention is:

1, at gettering container inwall, be evenly covered with rotating ball, the ball of rotation can give gined cotton the thrust to outlet, has eliminated the resistance of gettering container inwall to gined cotton, greatly reduced exhaust resistance, meanwhile, gined cotton can not produce eddy current on the ball rotating, and further reduces exhaust resistance;

2, the angle of the suction inlet of gettering container and the sidewall of gettering container is set to 55 °, further avoids air-flow in suction nozzle, to produce eddy current, further reduces the frictional impact of cotton fiber and gettering container inwall.

Above foundation desirable embodiment of the present invention is enlightenment, and by above-mentioned description, related personnel can, within not departing from the scope of this invention technological thought, carry out various change and modification completely.The technical scope of this invention is not limited to the content on description, must determine technical scope according to claim scope.

Claims (7)

1. a suction nozzle of drawing gined cotton, it is characterized in that: comprise that cross section is trapezoidal up-narrow and down-wide gettering container, the wider one end of described gettering container is suction inlet, narrower one end is outlet, the exit of described gettering container is provided with the carrier pipe being communicated with described gettering container, is equipped with several rotating balls on each inwall of described gettering container.

2. a kind of suction nozzle of drawing gined cotton according to claim 1, it is characterized in that: described ball is evenly covered with each inwall of described gettering container, the sandwich that described gettering container shell is hollow, described gettering container inwall is provided with several circular holes that can rotate for described ball, in the shell of described gettering container hollow, be laterally provided with some row's back shafts, described ball is inserted in described circular hole and part exposes to described circular hole and is applied in successively on described back shaft.

3. a kind of suction nozzle of drawing gined cotton according to claim 2, is characterized in that: the area of the cross section of described carrier pipe equates with the area of the outlet of described gettering container.

4. a kind of suction nozzle of drawing gined cotton according to claim 3, is characterized in that: the angle of the suction inlet of described gettering container and the sidewall of described gettering container is 40 °~60 °.

5. a kind of suction nozzle of drawing gined cotton according to claim 4, is characterized in that: seamless contact between described ball and described circular hole.

6. a kind of suction nozzle of drawing gined cotton according to claim 5, is characterized in that: described ball is made by stainless steel.

7. a kind of suction nozzle of drawing gined cotton according to claim 6, is characterized in that: the angle of the suction inlet of described gettering container and the sidewall of described gettering container is 55 °.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310663397.8A CN103668477A (en) | 2013-12-10 | 2013-12-10 | Suction nozzle sucking ginned cotton |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310663397.8A CN103668477A (en) | 2013-12-10 | 2013-12-10 | Suction nozzle sucking ginned cotton |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN103668477A true CN103668477A (en) | 2014-03-26 |

Family

ID=50307227

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201310663397.8A Pending CN103668477A (en) | 2013-12-10 | 2013-12-10 | Suction nozzle sucking ginned cotton |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN103668477A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115482995A (en) * | 2022-09-16 | 2022-12-16 | 广东电网有限责任公司广州供电局 | Connecting device for suction filtration equipment for replacing natural ester insulating oil of mineral oil transformer |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4860405A (en) * | 1988-04-26 | 1989-08-29 | Eckley Robert C | Apparatus for drying material transported in a fluid stream |

| US4988373A (en) * | 1989-06-01 | 1991-01-29 | Marzoli Pietro B | Impurity separator for cleaning staple cotton |

| CN2625396Y (en) * | 2003-03-21 | 2004-07-14 | 宜兴市恒通风机有限公司 | Suction case body |

| CN2656304Y (en) * | 2003-10-27 | 2004-11-17 | 北京中棉机械成套设备有限公司 | Lint cotton lumidification system |

| CN2837315Y (en) * | 2005-10-14 | 2006-11-15 | 张祺田 | Improvement for cotton suction horn duct of round bale plucker |

| CN201517146U (en) * | 2009-04-09 | 2010-06-30 | 江苏迎阳无纺机械有限公司 | Airflow vibration cotton feeding device |

| CN201605368U (en) * | 2010-02-02 | 2010-10-13 | 杭州晓行纺织有限公司 | Automatic plucker |

| CN102517710A (en) * | 2011-12-05 | 2012-06-27 | 铜陵市精特机械有限责任公司 | Cotton-suction flute pipe |

| CN202359394U (en) * | 2010-11-01 | 2012-08-01 | 三星电子株式会社 | Washer |

| CN202718638U (en) * | 2012-08-02 | 2013-02-06 | 四川天剑石油工程技术开发有限公司 | Superlow-resistance ball sleeve centering device |

| CN103103718A (en) * | 2011-11-11 | 2013-05-15 | 三星电子株式会社 | Washing machine |

| CN203683732U (en) * | 2013-12-10 | 2014-07-02 | 吴江市大业丝绸整理有限公司 | Suction nozzle for sucking ginned cotton |

-

2013

- 2013-12-10 CN CN201310663397.8A patent/CN103668477A/en active Pending

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4860405A (en) * | 1988-04-26 | 1989-08-29 | Eckley Robert C | Apparatus for drying material transported in a fluid stream |

| US4988373A (en) * | 1989-06-01 | 1991-01-29 | Marzoli Pietro B | Impurity separator for cleaning staple cotton |

| CN2625396Y (en) * | 2003-03-21 | 2004-07-14 | 宜兴市恒通风机有限公司 | Suction case body |

| CN2656304Y (en) * | 2003-10-27 | 2004-11-17 | 北京中棉机械成套设备有限公司 | Lint cotton lumidification system |

| CN2837315Y (en) * | 2005-10-14 | 2006-11-15 | 张祺田 | Improvement for cotton suction horn duct of round bale plucker |

| CN201517146U (en) * | 2009-04-09 | 2010-06-30 | 江苏迎阳无纺机械有限公司 | Airflow vibration cotton feeding device |

| CN201605368U (en) * | 2010-02-02 | 2010-10-13 | 杭州晓行纺织有限公司 | Automatic plucker |

| CN202359394U (en) * | 2010-11-01 | 2012-08-01 | 三星电子株式会社 | Washer |

| CN103103718A (en) * | 2011-11-11 | 2013-05-15 | 三星电子株式会社 | Washing machine |

| CN102517710A (en) * | 2011-12-05 | 2012-06-27 | 铜陵市精特机械有限责任公司 | Cotton-suction flute pipe |

| CN202718638U (en) * | 2012-08-02 | 2013-02-06 | 四川天剑石油工程技术开发有限公司 | Superlow-resistance ball sleeve centering device |

| CN203683732U (en) * | 2013-12-10 | 2014-07-02 | 吴江市大业丝绸整理有限公司 | Suction nozzle for sucking ginned cotton |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115482995A (en) * | 2022-09-16 | 2022-12-16 | 广东电网有限责任公司广州供电局 | Connecting device for suction filtration equipment for replacing natural ester insulating oil of mineral oil transformer |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103147134B (en) | The efficient cotton ginning machinery of anti-resorption | |

| CN207154245U (en) | A kind of multi-functional traditional Chinese medicine material highly-efficient processing device | |

| CN107101492B (en) | A kind of grain drying cleaner | |

| CN203683732U (en) | Suction nozzle for sucking ginned cotton | |

| CN103668477A (en) | Suction nozzle sucking ginned cotton | |

| CN107986036A (en) | A kind of grain purchasing machine inhales grain device | |

| CN203683775U (en) | Efficient ginned cotton suction nozzle | |

| CN204401185U (en) | A kind of combing machine noil sucking air channel | |

| CN207524681U (en) | A kind of carpet winds cleaning device | |

| CN207575696U (en) | A kind of portable tennis collector | |

| CN202730422U (en) | Dedusting structure for flat knitting machine | |

| CN216614950U (en) | Special beater for grabbing long fibers by disc bale plucker | |

| CN206089901U (en) | Feed hopper suitable for clear comb allies oneself with flow area impurity removal function | |

| CN215251387U (en) | Hair coagulating device | |

| CN203307484U (en) | Anti-suck-back efficient cotton ginning machine | |

| CN203683774U (en) | Novel ginned cotton suction nozzle | |

| CN203999979U (en) | For the clean recovery unit of combing machine drafting roller | |

| CN203683776U (en) | Adjustable cotton lint suction nozzle | |

| CN103643356A (en) | Efficient ginned cotton suction nozzle | |

| CN202369682U (en) | Cotton machining all-in-one machine | |

| CN206768297U (en) | The cotton receiving device of disc bale plucker | |

| CN203700592U (en) | Cotton suction box | |

| CN208364439U (en) | A kind of spray drying storehouse air blower | |

| CN103668478A (en) | Cotton suction box for drying cotton | |

| CN217289611U (en) | Multifunctional traditional Chinese medicine sterilization equipment with dust removal function |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |

Application publication date: 20140326 |