CN102622012B - Device and method for heating and heat preserving of optical devices - Google Patents

Device and method for heating and heat preserving of optical devices Download PDFInfo

- Publication number

- CN102622012B CN102622012B CN201210085492.XA CN201210085492A CN102622012B CN 102622012 B CN102622012 B CN 102622012B CN 201210085492 A CN201210085492 A CN 201210085492A CN 102622012 B CN102622012 B CN 102622012B

- Authority

- CN

- China

- Prior art keywords

- circuit

- heater

- thermopair

- heating

- temperature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Landscapes

- Control Of Resistance Heating (AREA)

Abstract

The invention relates to a device and a method for heating and heat preserving of optical devices, in particular to a device and a method for temperature control of optical devices in operation at low temperature, which belong to the photoelectronic technical field. The device for heating and heat preserving of optical devices comprises a heater, a heat insulation layer, a waterproof coating, a cavity shell, a control circuit, a thermocouple, a heater lead and a thermocouple lead. Low-temperature heating of optical devices is controlled by the device and the method to enable the devices to operate normally in the low-temperature environment, and the problem that the optical devices cannot be used normally in severe environments is solved. Heating and heat preserving of the optical devices are automatically controlled by means of the control circuit to enable the optical devices to operate normally in a wide temperature range, and the device and the circuit have the advantage of wide temperature control range. The heat insulation layer I used for temperature isolation of the controlled optical device from an external environment, the waterproof coating is arranged outside the heat insulation layer and used for closing, and the cavity shell is used for packaging integrally, so that heating and heat preserving efficiency can be improved, and power consumption in heating and heat preserving is reduced.

Description

Technical field

The present invention relates to a kind of optical device heating and heat-insulating device and method, relate in particular to a kind of temperature control equipment and method while working under cryogenic conditions for optical device, belong to the photoelectron technology field.

Background technology

Optical device is connection for realizing light signal, the energy general name of the function components and parts such as /He road, wavelength multiplexing/demultiplexing, light path converting, energy attenuation, direction obstruct, light-electrical-optical conversion, optical signal amplification, optical signal modulation along separate routes.Optical device, due to characteristics such as its electrical insulating property, anti-electromagnetic interference (EMI), is widely used in recent years Fibre Optical Sensor and measures and fiber optic communication field.

At present, most of optical devices are affected by principle of work and inner structure, and its normal working temperature can not be lower than-20 ℃, and especially Passive Optical Components serviceability under cryogenic conditions such as optical filter is poor, luminous energy by wherein changes greatly, when lower than-20 ℃ of work, can be damaged.Therefore, it being carried out to temperature controls just particularly important.

Existing optical device temperature-controlled process comprises the control of vacuum insulation temperature and phase-change material temperature control etc.But, the problem that can't normally use in rugged surroundings for optical device, the vacuum insulation temperature control mode is not suitable for having the optical device of fiber-optic wire, because more lead-in wire not only affects the effect of vacuum insulation, and the extruding of pressure can affect the transmission of luminous energy in fiber-optic wire greatly, and then affect the serviceability of optical device.And the temperature control scope that phase-change material temperature is controlled is confined near the solidifying point of phase-change material, be not suitable for the requirement of wide temperature working range in rugged surroundings.

Summary of the invention

The objective of the invention is, in order to solve optical device poor problem of serviceability under lower than-20 ℃ of conditions, to propose a kind of optical device heating and heat-insulating device and method.

The present invention is achieved through the following technical solutions:

A kind of optical device heating and heat-insulating device, comprise well heater, thermofin, water-proof coating, shell cavity, control circuit, thermopair, heater lead and thermocouple lead.

Described well heater is for being heated the controlled light device during lower than threshold value in temperature, in the scope that the environment temperature of its work is allowed in design.

Described thermofin is for carrying out temperature isolation to the controlled light device, and the speed that makes the controlled light device temperature underspeed and reduce much smaller than environment temperature, when well heater is worked, stop heat outwards to distribute, and improves the efficiency of heating surface.Thermofin requires to use coefficient of heat conductivity to be not more than the insulation material of 0.12 watt/meter degree centigrade, as mineral fibres, glass fibre etc.

Described water-proof coating is used for preventing when temperature from changing between height producing solidifying water, and controlled light device serviceability is exerted an influence.The thickness of water-proof coating should not surpass 1mm.

Described control circuit is for automatically controlling the open and close of well heater, this circuit comprises bleeder circuit, subtraction circuit, amplification appliance, comparator circuit and relay, its annexation is: the output terminal of thermopair is connected with the input end of bleeder circuit, the output terminal of bleeder circuit is connected with the input end of subtraction circuit, the output terminal of subtraction circuit is connected with the input end of amplifying circuit, the output terminal of amplifying circuit is connected with the input end of comparator circuit, the output terminal of comparator circuit is connected with the input end of relay, the output terminal of relay is connected with the input end of heater-driven voltage, the output terminal of heater-driven voltage is connected with the input end of thermopair, the output terminal of reference voltage is connected with the input end of subtraction circuit.

Described thermopair is used for feedback controlled optical device current temperature value, the respective value using the resistance measurement value as controlled light device current temperature value, and the resistance measurement value is delivered in control circuit as circuit parameter.

Described heater lead is for inputting the driving voltage of well heater.

Described thermocouple lead is for by controlled light device current temperature value, corresponding resistance measurement value is delivered to control circuit.

Described shell cavity is for being closed controlled light device and above-mentioned each building block.

The annexation of above-mentioned building block is:

Well heater be pasted on the controlled light device around, thermopair sticks on controlled light device one side.Wherein, the controlled light device is pasted with a side of thermopair can not paste well heater, and the paste position of thermopair will be as far as possible away from well heater.

Thermofin is wrapped in outside well heater, and water-proof coating spreads upon outside thermofin.Shell cavity is wrapped in the water-proof coating surrounding.Simultaneously, the shell cavity left and right side has aperture, for heater lead, thermocouple lead are drawn.Thermocouple lead, heater lead are connected with control circuit.

A kind of method of using said apparatus sun adjuster part to carry out heat tracing comprises the following steps:

At first, obtain resistance measurement value corresponding to controlled light device current temperature value by thermopair, and the resistance measurement value is delivered in control circuit as circuit parameter.

Afterwards, in control circuit, the resistance measurement value obtained is analyzed, determined controlled light device Current Temperatures environment.Judge that current environmental temperature whether in this device normal working temperature scope, if surpass lower limit or the upper limit of its normal working temperature, opens or close the well heater heating arrangement automatically.

Beneficial effect

Device and method of the present invention, the contrast prior art has the following advantages:

1. sun adjuster part of the present invention carries out low-temperature heat control, can make device work under low temperature environment, has solved the problem that optical device can't normally be used in rugged surroundings.

2. the present invention controls by control circuit the heat tracing of realizing optical device automatically, and it can be worked in wide temperature range, has advantages of the temperature control wide ranges.

3. the present invention uses thermofin to carry out temperature isolation to controlled light device and external environment, and outside thermofin, uses water-proof coating to be sealed, and uses shell cavity to be encapsulated integral body, has improved the efficiency of heat tracing, reduced heat tracing power consumption.

The accompanying drawing explanation

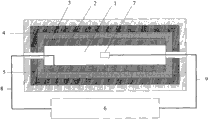

Fig. 1 is heating and heat-insulating device schematic diagram of the present invention;

Fig. 2 is that in device of the present invention, control circuit forms schematic diagram;

Fig. 3 is the described controlled light device of the embodiment of the present invention 1 schematic top plan view;

Fig. 4 is the described controlled light device of the embodiment of the present invention 1 elevational schematic view;

Fig. 5 is the described controlled light device of the embodiment of the present invention 2 schematic top plan view;

Fig. 6 is the described controlled light device of the embodiment of the present invention 2 elevational schematic view;

Wherein, before 1-controlled light device, 2-well heater, 3-thermofin, 4-water-proof coating, 5-shell cavity, 6-control circuit, 7-thermopair, 8-heater lead, 9-thermocouple lead, 10-FP wave filter, on the 11-FP wave filter, after the 12-FP wave filter, on 13-FP wave filter lead-in wire, 14-FP wave filter weldering leg, 15-FP wave filter bottom surface, 16-sonet standard tool, 17-sonet standard tool lead-in wire, 18-sonet standard tool bottom surface.

Embodiment

Below in conjunction with drawings and Examples, technical scheme of the present invention is described in further detail.

In the present embodiment, will use the inventive method and device to carry out heat tracing to the FP wave filter controls automatically.

As Fig. 1, described optical device heating and heat-insulating device comprises that well heater 2, thermofin 3, water-proof coating 4, shell cavity 5, control circuit 6, thermopair 7, heater lead 8, thermocouple lead 9 form.

As shown in Figure 3, Figure 4, controlled light device 1 is the rectangular parallelepiped device for the FP wave filter, and there is FP wave filter weldering leg 14 FP wave filter bottom surface 15,13 turnover of the left and right sides from controlled light device 1 of FP wave filter lead-in wire, therefore, shell cavity 5 left and right sides of this heating and heat-insulating device have the optical fiber manhole appendix, You Hantui hole, bottom surface.

Annexation for the heating and heat-insulating device of this FP wave filter is as follows:

The FP wave filter is front 10, and after the FP wave filter 12, on the FP wave filter, well heaters 2 are pasted in 11 3 sides, paste thermopair 7 on FP wave filter bottom surface 15; Wherein, FP wave filter bottom surface 15 is pasted with a side of thermopair 7 can not paste well heater 2, and the paste position of thermopair 7 will be as far as possible away from well heater 2;

Thermofin 3 is coated on outside well heater 2, and water-proof coating 4 coats outside thermofin 3, and shell cavity 5 coats water-proof coating 4;

By thermocouple lead 9, in heater lead 8 Access Control circuit 6, form miniature heating and heat-insulating device.

As Fig. 2, the heating heat preserving method of this FP wave filter comprises the following steps:

At first, thermopair 7 imports current resistance into circuit, and bleeder circuit is converted to magnitude of voltage by resistance, and resistance is larger and magnitude of voltage is larger, linear.

Secondly, subtraction circuit deducts reference voltage by partial pressure value, obtains the difference of measured value and reference value.

Again, through amplifying circuit, difference is amplified to 10 times.Subtraction circuit and amplifying circuit cascade, effect is that the difference of the magnitude of voltage that two different temperatures is corresponding amplifies 10 times, is easy to be compared the device circuit and differentiates.

Then, by comparator circuit output control relay switching voltage ,-10 ℃ of unlatchings, close for 30 ℃.When relay is opened, the work of heating plate driving voltage, heated the FP wave filter, and when cut-off, the heating plate driving voltage quits work.

Finally, during the temperature change of FP wave filter, by thermopair 7 feedback current temperature value, through processing of circuit, form closed loop and automatically control.

In the present embodiment, will use the inventive method and device to carry out heat tracing to the sonet standard tool controls automatically.

As Fig. 1, described optical device heating and heat-insulating device comprises that well heater 2, thermofin 3, water-proof coating 4, shell cavity 5, control circuit 6, thermopair 7, heater lead 8, thermocouple lead 9 form.

As shown in Figure 5, Figure 6, controlled light device 1 is the rectangular parallelepiped device for the sonet standard tool, 17 turnover of the left and right sides from controlled light device 1 of sonet standard tool lead-in wire, and therefore, shell cavity 5 left and right sides of this heating and heat-insulating device have the optical fiber manhole appendix.

Annexation for the heating and heat-insulating device of this sonet standard tool is as follows:

On the sonet standard tool, 16 paste well heater 2, paste thermopair 7 on sonet standard tool bottom surface 18; Wherein, sonet standard tool bottom surface 18 is pasted with a side of thermopair 7 can not paste well heater 2, and the paste position of thermopair 7 will be as far as possible away from well heater 2;

By thermocouple lead 9, in heater lead 8 Access Control circuit 6, form miniature heating and heat-insulating device.

As Fig. 2, the heating heat preserving method of this sonet standard tool comprises the following steps:

At first, thermopair 7 imports current resistance into circuit, and bleeder circuit is converted to magnitude of voltage by resistance, and resistance is larger and magnitude of voltage is larger, linear.

Secondly, subtraction circuit deducts reference voltage by partial pressure value, obtains the difference of measured value and reference value.

Again, through amplifying circuit, difference is amplified to 10 times.Subtraction circuit and amplifying circuit cascade, effect is that the difference of the magnitude of voltage that two different temperatures is corresponding amplifies 10 times, is easy to be compared the device circuit and differentiates.

Then, by comparator circuit output control relay switching voltage ,-10 ℃ of unlatchings, close for 30 ℃.When relay is opened, the work of heating plate driving voltage, heated the FP wave filter, and when cut-off, the heating plate driving voltage quits work.

Finally, during the temperature change of sonet standard tool, by thermopair 7 feedback current temperature value, through processing of circuit, form closed loop and automatically control.

Although described by reference to the accompanying drawings embodiments of the present invention, to those skilled in the art, under the premise without departing from the principles of the invention, can also make some distortion and improvement, these also should be considered as belonging to protection scope of the present invention.

Claims (3)

1. an optical device heating and heat-insulating device, it is characterized in that: by well heater (2), thermofin (3), water-proof coating (4), shell cavity (5), control circuit (6), thermopair (7), heater lead (8) and thermocouple lead (9), formed

Wherein said well heater (2) is for being heated controlled light device (1) during lower than threshold value in temperature;

Described thermofin (3) is for carrying out temperature isolation to controlled light device (1);

Described water-proof coating (4) produces solidifying water when preventing that temperature from changing between height;

Described control circuit (6) is controlled automatically for the open and close to well heater, this circuit comprises bleeder circuit, subtraction circuit, amplification appliance, comparator circuit and relay, its annexation is: the output terminal of thermopair is connected with the input end of bleeder circuit, the output terminal of bleeder circuit is connected with the input end of subtraction circuit, the output terminal of subtraction circuit is connected with the input end of amplifying circuit, the output terminal of amplifying circuit is connected with the input end of comparator circuit, the output terminal of comparator circuit is connected with the input end of relay, the output terminal of relay is connected with the input end of heater-driven voltage, the output terminal of heater-driven voltage is connected with the input end of thermopair, the output terminal of reference voltage is connected with the input end of subtraction circuit,

Described thermopair (7) is for feedback controlled optical device (1) current temperature value, the respective value using the resistance measurement value as controlled light device current temperature value, and using the resistance measurement value as circuit parameter, be delivered in control circuit (6);

Described heater lead (8) is for inputting the driving voltage of well heater (2);

Described thermocouple lead (9) is delivered to control circuit (6) for the resistance measurement value that controlled light device current temperature value is corresponding;

Described shell cavity (5) is for being closed controlled light device (1) and above-mentioned each building block;

The effect of above-mentioned each building block and mutual annexation are as follows:

Well heater (2) be pasted on controlled light device (1) around, thermopair (7) sticks on controlled light device (1) one side; Wherein, controlled light device (1) is pasted with a side of thermopair (7) can not paste well heater (2), and the paste position of thermopair (7) will be as far as possible away from well heater (2);

Thermofin (3) is wrapped in outside well heater (2), water-proof coating (4) spreads upon outside thermofin (3), shell cavity (5) is wrapped in water-proof coating (4) surrounding, shell cavity (5) left and right side has aperture simultaneously, for heater lead (8), thermocouple lead (9) are drawn; Thermocouple lead (9), heater lead (8) are connected with control circuit (6);

The process that use said apparatus sun adjuster part carries out heat tracing is as follows:

At first, obtain resistance measurement value corresponding to controlled light device (1) current temperature value by thermopair (7), and be delivered to the resistance measurement value as circuit parameter in control circuit (6);

Afterwards, in control circuit (6), the resistance measurement value obtained is analyzed, determined controlled light device (1) Current Temperatures environment; Judge that current environmental temperature whether in this device normal working temperature scope, if surpass lower limit or the upper limit of its normal working temperature, opens or close well heater (2) heating arrangement automatically.

2. a kind of optical device heating and heat-insulating device according to claim 1 is characterized in that: described thermofin (3) requires to use coefficient of heat conductivity to be not more than the insulation material of 0.12 watt/meter degree centigrade.

3. a kind of optical device heating and heat-insulating device according to claim 1, it is characterized in that: the thickness of described water-proof coating (4) should not surpass 1mm.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201210085492.XA CN102622012B (en) | 2012-03-28 | 2012-03-28 | Device and method for heating and heat preserving of optical devices |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201210085492.XA CN102622012B (en) | 2012-03-28 | 2012-03-28 | Device and method for heating and heat preserving of optical devices |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN102622012A CN102622012A (en) | 2012-08-01 |

| CN102622012B true CN102622012B (en) | 2014-01-08 |

Family

ID=46561975

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201210085492.XA Active CN102622012B (en) | 2012-03-28 | 2012-03-28 | Device and method for heating and heat preserving of optical devices |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN102622012B (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105807813A (en) * | 2014-12-31 | 2016-07-27 | 无锡汉思特电器科技有限公司 | Electric ceramic cooker control circuit |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1391134A (en) * | 2002-07-26 | 2003-01-15 | 中国科学院上海光学精密机械研究所 | Metallized optical fiber distributed micro-heater for temperature tuning of optical fiber device |

| JP2011209379A (en) * | 2010-03-29 | 2011-10-20 | Lintec Corp | Adhesive composition for optical filter, adhesive, and adhesive sheet |

| CN102768418A (en) * | 2012-07-06 | 2012-11-07 | 华中科技大学 | Optical filter and optical filtering method based on linear chirped fiber Bragg grating |

| CN202677231U (en) * | 2012-03-28 | 2013-01-16 | 中国航空工业集团公司北京长城计量测试技术研究所 | Device for heating and heat preserving of optical devices |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20030180062A1 (en) * | 2002-03-25 | 2003-09-25 | Brother Kogyo Kabushiki Kaisha | Fixing device provided with calculation unit for calculating temperature of fixing member |

-

2012

- 2012-03-28 CN CN201210085492.XA patent/CN102622012B/en active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1391134A (en) * | 2002-07-26 | 2003-01-15 | 中国科学院上海光学精密机械研究所 | Metallized optical fiber distributed micro-heater for temperature tuning of optical fiber device |

| JP2011209379A (en) * | 2010-03-29 | 2011-10-20 | Lintec Corp | Adhesive composition for optical filter, adhesive, and adhesive sheet |

| CN202677231U (en) * | 2012-03-28 | 2013-01-16 | 中国航空工业集团公司北京长城计量测试技术研究所 | Device for heating and heat preserving of optical devices |

| CN102768418A (en) * | 2012-07-06 | 2012-11-07 | 华中科技大学 | Optical filter and optical filtering method based on linear chirped fiber Bragg grating |

Also Published As

| Publication number | Publication date |

|---|---|

| CN102622012A (en) | 2012-08-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN203561385U (en) | Power transmission line on-line parameter monitoring system based on fiber-electromechanical sensor | |

| CN202677231U (en) | Device for heating and heat preserving of optical devices | |

| CN103955147A (en) | Control device of micro-ring optical switch | |

| GB2477890A (en) | Electricity meter and method of operating the electricity meter | |

| CN105044928B (en) | A kind of optical drive all -fiber phase-shifter of graphene auxiliary | |

| CN102622012B (en) | Device and method for heating and heat preserving of optical devices | |

| CN102853778A (en) | Fiber grating strain sensor | |

| CN206960984U (en) | A kind of quantum optices module temperature control device based on pulse width modulation | |

| CN102298183A (en) | Er-doped optical fiber junction box | |

| CN101957479A (en) | Method for realizing output of optical microcavity coupling system by temperature modulation and coupling structure thereof | |

| CN108511830A (en) | A kind of lithium battery | |

| CN106506092B (en) | A kind of low noise radio-frequency light transmission module of wide temperature range work | |

| CN112526771A (en) | Molybdenum disulfide film assisted thermo-optic modulator | |

| CN107229138A (en) | Full light opens the light device and its operating method | |

| CN204497558U (en) | The Erbium-Doped Fiber Amplifier of pump power high efficiency conversion | |

| CN111880065A (en) | Built-in metal foil electrode sensor and preparation method thereof | |

| CN206992473U (en) | The temperature control equipment of ROF radio frequency fiber optic transmitting modules is integrated for multichannel | |

| CN203719790U (en) | NTC identification circuit with high return difference | |

| CN212811263U (en) | Novel T-shaped cable joint | |

| CN203589695U (en) | Transformer cable connector temperature measuring and monitoring system | |

| CN203259266U (en) | Smart power grid plastic optical fiber temperature sensing system | |

| CN204007933U (en) | A kind of fiber-optical grating temperature sensor that is applied to power equipment | |

| CN203287113U (en) | Electric power device connecting part temperature online monitoring system | |

| CN204536756U (en) | A kind of indoor environment supervisory system based on signal light control | |

| CN203324474U (en) | Extended temperature type precise laser distance measuring instrument |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant |