CN101672990B - Zoom liquid crystal lens - Google Patents

Zoom liquid crystal lens Download PDFInfo

- Publication number

- CN101672990B CN101672990B CN2008102123513A CN200810212351A CN101672990B CN 101672990 B CN101672990 B CN 101672990B CN 2008102123513 A CN2008102123513 A CN 2008102123513A CN 200810212351 A CN200810212351 A CN 200810212351A CN 101672990 B CN101672990 B CN 101672990B

- Authority

- CN

- China

- Prior art keywords

- liquid crystal

- electrode

- layer

- glass substrate

- crystal lens

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Liquid Crystal (AREA)

Abstract

The invention provides a zoom liquid crystal lens, which comprises a single-layer or multi-layer liquid crystal lens unit. The liquid crystal lens unit utilizes at least two pieces of glass substrates in a scheduled thickness; an aluminium film, a silver film or other translucent metal films are arranged on one side or double sides of each glass substrate respectively in an etching mode to form a surface alignment electrode which can be controlled independently; and then the glass substrates are arranged in parallel at intervals, so that a layer of accommodating space in a predetermined thickness is arranged between two adjacent glass substrates to seal liquid crystals so as to form a layer of liquid crystal lens unit. The arrangement direction and the optical properties such as the refractive index and the like of liquid crystal molecules in each liquid crystal lens unit are independently controlled by voltage so as to improve the imaging quality, accelerate zoom switching, improve the convenience of assembling the zoom liquid crystal lens and reduce the overall lens thickness and the manufacturing cost.

Description

Technical field

The present invention relates to a kind of liquid crystal lens, relates in particular to a kind of Zoom liquid crystal lens.

Background technology

Devices such as camera, mobile phone camera or stereopsis processing often utilize zoom lens that image is amplified or dwindle with imaging.The traditional zoom camera lens is provided with a plurality of mirror crowds (lens group), through moving along optical axis direction between the mirror crowd, with change spacing to each other, and whole focal length is changed, but does not influence image-forming range.Right this kind camera lens needs long mirror crowd displacement, and its distance be nonlinear relationship, therefore difficulty very on structural design, control accuracy, and cost is Ju Gao and be difficult to reduction also.Other has use liquid lens (liquid lens) or liquid crystal camera lens (liquid crystal lens is called for short LC lens), to improve the distance that the mirror crowd moves, to dwindle the size of camera.But the principle of liquid lens is made up of liquid filling lens and a solid lens of a modulation; Can utilize the shape (biconvex or concavo-convex) that changes the liquid filling lens or the filling medium that changes different refractivity adjusts lens focus to reach the zoom purpose; Like " Liquid-Crystal Lens-Cells withVariable Focal Length ", author is Sus μ mu Sato, Japan J.of Applied physics, on March 12nd, 1979; U.S. Pat 2007/0217023.In addition, the principle of varifocal liquid crystal camera lens is to utilize inhomogeneous field to be applied to non-homogeneous liquid crystal layer; Or inhomogeneous field is applied to even liquid crystal layer; Or uniform electric field is applied to non-homogeneous liquid crystal layer, and producing the refractive index of a gradual change, and the adjustment lens focus is to reach the zoom purpose; Like the author is Yun-Hsing Fan etc.; Name is called " Liquid crystal microlens arrayswith switchable positive and negative focal lengths ", Journal of Display Technology, in September, 2005.

Because liquid crystal has good photoelectric characteristic and very low operating voltage, once can automatically controlled optical modulation element to extensively being used to make.Existing liquid crystal lens technology; Shown in Figure 1A; Mainly be that liquid crystal molecule 103 is sealed up for safekeeping between two plate electrodes 102, utilize row that the changes in distribution of voltage between two electrodes changes liquid crystal molecule to, and then change light path characteristic through this liquid crystal lens aperture to reach Zoom effect.The available liquid crystal lens electrode is employed in glass plate 102 surfaces more and plates one deck ITO transparent conductive film to form ITO electrode 101; And ITO is indium oxide (the Indi μ m Tin Oxide of doped tin; Or Tin-doped Indi μ m Oxide; Be called for short ITO); Because it has the permeability and the high IR reflection of light property of splendid conductive characteristic (resistance coefficient can be about 100 times of best conductor silver metal to 2 * 10-4 Ω .cm) and high visible, used in LCD and liquid crystal lens by development and application; On its structure,, can be two ITO films or a slice ITO film and cooperate a slice metal coating to constitute in the liquid crystal layer both sides; Like Figure 1A, on ITO101, add inhomogeneous field, said electric field is applied on the even liquid crystal material 103, the variation that will produce the thickness of contact, the refractive index of change liquid crystal lens makes liquid crystal lens be transformed into focusing by non-focusing, or changes its focal length; Like U.S. Pat 6,882,390, US7,388,822, US2007/0183293 Taiwan patent TWM327490, Jap.P. JP08-258624, WIPO patent WO/1993/009524 etc.But because the voltage that the ITO transparent conductive film need use is higher, when forming liquid crystal camera lens (being the liquid crystal lens module) with liquid crystal, its reaction time is longer, and switch speed is slow, is not suitable for camera or mobile lens and uses.

For alternative ITO material; Prior art still has on glass substrate the plated aluminum film and etches specific aperture with as electrode; Like Figure 1B, like the further low-resistance aluminium of public use, gold, silver or chromium and high-resistance zinc paste, massicot or indium oxide collocation of U.S. Pat 2007/0183293, US2007/0182915; U.S. US2007/0024801 patent then discloses heat transfer medium and uses golden film (gold film); Through imposing voltage reaches zoom to mode with the row who changes liquid crystal in the aperture purpose; Or conduct with Rapid Thermal.Because between the liquid crystal molecule levels; Owing to use the electrode of different configurations; Cause electric field different,, also form the edge relaxation phenomenon and cause image quality not good though can form the refractive index of gradual change; Or have that high operation voltage, focusing efficiency are not high, focusing efficiency and polarization are dependence, and shortcoming such as adjustable focal range is big inadequately, cause and still have many restrictions in the use; And for addressing the above problem; Prior art often need be arranged in pairs or groups other conventional lenses to form combined type lens; With compensation zoom rate and image quality, but also increase whole thickness and cost relatively, and still can't effectively solve the problem of zoom switch speed.

Summary of the invention

Fundamental purpose of the present invention is to provide a kind of Zoom liquid crystal lens; It utilizes the glass substrate of at least two predetermined thickness, and through surperficial orientation electrode or the double-sided metal etched surperficial orientation electrode of etching mode with formation single face metal etch on glass substrate; Seal up for safekeeping liquid crystal molecule such as the said glass substrate that waits with preset space length again, to constitute the liquid crystal lens unit; Further utilize the liquid crystal lens unit to form the single or multiple lift Zoom liquid crystal lens; And the row who can voltage comes liquid crystal molecule in each liquid crystal lens unit of independent regulation and control to; Produce predetermined optical characteristics, supply with the zoom purpose of device camera lenses such as camera, mobile phone camera or stereopsis processing and use.

For reaching above-mentioned purpose; Individual layer Zoom liquid crystal lens of the present invention comprises individual layer liquid crystal lens unit; The glass substrate of two predetermined thickness of said liquid crystal lens unit by using is arranged and is constituted; Utilize the metal film of aluminium film, silverskin or other light-permeables,, existing by the ITO (indium oxide of doped tin through etching mode to replace on glass substrate, to constitute the surperficial orientation electrode or the etched surperficial orientation electrode of double-sided metal of single face metal etch; Tin-doped Indi μ m Oxide is called for short ITO) electrode structure that forms of transparent conductive film; Wherein, the surperficial orientation electrode of said metal etch can be symmetry on the both sides of glass substrate (two-sided), and forms the surperficial orientation electrode of identical orientation pattern; Or said surperficial orientation electrode can be surperficial orientation electrode asymmetric and formation different alignment pattern; Said two sheet glass substrates are arranged with the preset space length parallel interval, constituted room, and in room, load liquid crystal material, constitute individual layer liquid crystal lens unit; When imposing specific voltage, can make liquid crystal produce specific refractive index and optical characteristics in surperficial orientation electrode; Can produce different refractive indexes and optical characteristics for imposing different voltages, and produce the Zoom effect of Zoom liquid crystal lens.

Another object of the present invention is to provide a kind of Zoom liquid crystal lens; Comprise bilayer or liquid crystal lens unit more than three layers; The glass substrate of at least two predetermined thickness of said liquid crystal lens unit by using is arranged and is constituted; Utilize the metal film of aluminium film, silverskin or other light-permeables, through surperficial orientation electrode or the double-sided metal etched surperficial orientation electrode of etching mode with formation single face metal etch on glass substrate; Wherein, the surperficial orientation electrode of said metal etch can be symmetry and forms the surperficial orientation electrode of identical orientation pattern on glass substrate both sides (two-sided); Or said surperficial orientation electrode can be surperficial orientation electrode asymmetric and formation different alignment pattern; Two sheet glass substrates are arranged with the preset space length parallel interval, constituted room, and in room, load liquid crystal material, constitute the liquid crystal lens unit of bilayer or multilayer; When imposing the surperficial orientation electrode of specific voltage, can make liquid crystal produce specific refractive index and optical characteristics in each layer; Then can produce different refractive indexes and optical characteristics for imposing different voltages, and produce the Zoom effect of Zoom liquid crystal lens.

Another purpose of the present invention is to provide a kind of Zoom liquid crystal lens; The formed surperficial orientation electrode of metal etch for the glass baseplate surface of single or multiple lift liquid crystal lens unit; Can be designed to monotrysian type or concentric-ring pattern orientation pattern, so that the multiple variation of optical characteristics such as aperture, refractive index, focal length to be provided.

A purpose more of the present invention is to provide a kind of Zoom liquid crystal lens; To improve the liquid crystal lens that existing ITO constitutes; Because the structure of the liquid crystal lens that existing ITO constitutes is in the liquid crystal layer both sides, can be two ITO films or a slice ITO film and cooperate a slice to be constituted, the two sheet glass substrate surface orientation electrode surfaces that therefore contact at liquid crystal by metal coating; It is the situation of unlike material; When imposing voltage, the drag (anchoring force) that material different surface orientation electrode causes for liquid crystal has a little gap, thereby has influence on the last polarisation character of liquid crystal lens aperture; For improving this phenomenon, one of characteristic of the present invention can be easy to adjust to good symmetry for adopt the surperficial orientation electrode of identical material in the liquid crystal layer both sides, reduces liquid crystal lens aperture eccentricity issues.

Compared with prior art; Zoom liquid crystal lens of the present invention can need according to optical design; The single or multiple lift liquid crystal lens unit of the different numbers of plies of arranging in pairs or groups and different surfaces orientation electrode through the voltage of independent control liquid crystal lens unit, produce changes in optical properties such as refractive index, aperture size; To improve optical effect and the zoom quality that zoom switches speed and optimizes whole liquid crystal lens module, can reduce whole camera lens thickness and cost of manufacture.

Description of drawings

Figure 1A, 1B are the schematic side view of existing Zoom liquid crystal lens.

Fig. 2 is the schematic appearance of individual layer liquid crystal lens of the present invention unit.

Fig. 3 is the outward appearance decomposing schematic representation of individual layer liquid crystal lens of the present invention unit.

Fig. 4 A is the electric field action synoptic diagram (upper and lower laminar surface orientation electrode is asymmetric) of surperficial orientation electrode.

Fig. 4 B is the situation synoptic diagram of liquid crystal molecule when Fig. 4 A electric field action.

Fig. 5 A is the electric field action synoptic diagram (upper and lower laminar surface orientation electrode symmetry) of surperficial orientation electrode.

Fig. 5 B is the situation synoptic diagram of liquid crystal molecule when Fig. 5 A electric field action.

Fig. 6 is the synoptic diagram that concerns of refractive index and incident angle.

Fig. 7 A, 7B, 7C are the light path synoptic diagram of liquid crystal lens unit (first embodiment) when in different electric fields, producing different refractivity.

Fig. 8 is the manufacturing synoptic diagram of double-face electrode glass substrate.

Fig. 9 is the texture edge and the light path synoptic diagram of double-deck liquid crystal lens of the present invention unit (second embodiment).

Figure 10 is the texture edge and the light path synoptic diagram of three layers of liquid crystal lens unit of the present invention (the 3rd embodiment).

Description of reference numerals: Zoom liquid crystal lens-1,2,3; Glass substrate-10; Single-side electrode glass substrate-10a; Double-face electrode glass substrate-10b; Aperture-11; Surface orientation electrode-20,20a, 20b; Liquid crystal layer-30; Distance piece-40; Metal film-50; Photoresist layer-51; Light shield-52.

Embodiment

Below in conjunction with accompanying drawing, do more detailed explanation with other technical characterictic and advantage to the present invention is above-mentioned.

The embodiment that is disclosed below the present invention; Be to explain to the main composition element of Zoom liquid crystal lens of the present invention; Therefore with regard to general liquid crystal lens modular structure; The composed component that it will be understood by those skilled in the art that the disclosed Zoom liquid crystal lens of the present invention is not restricted to following the disclosed embodiments structure, and just said each composed component of Zoom liquid crystal lens can carry out many changes, modification even equivalence change; For example: the face shaping design of said Zoom liquid crystal lens does not limit, or the orientation pattern of surperficial orientation electrode does not limit yet.

Fig. 4 A is depicted as the synoptic diagram of the line of electric force of simple electric field, if upper surface orientation electrode 20a and following laminar surface orientation electrode 20b difference positively charged and negative electricity, then line of electric force is located to produce non-directional situation on the edge of.When after loading into liquid crystal layer 30 between surperficial orientation electrode 20a and surperficial orientation electrode 20b; Shown in Fig. 4 B; When upper surface orientation electrode 20a and following laminar surface orientation electrode 20b difference positively charged and negative electricity, the liquid crystal molecule of liquid crystal layer 30 receives electric field to produce moment, is desirable state of minimum energy; The main axis of the liquid crystal molecule of liquid crystal layer 30 is arranged parallel with extra electric field (along the tangential direction of electric field), forms particular arrangement and produces specific refractive index and optical characteristics.Because the structure of the liquid crystal molecule of said liquid crystal layer 30 is an anisotropy, has birefringent characteristic, when light during through said liquid crystal layer 30; The polarization of light direction can be relevant with the main axis of liquid crystal molecule; Incident light makes liquid crystal molecule produce polarization at the light field component of quadrature, when for electric field edge (the for example edge of two electrode wires), the zone outside electric field edge effect scope; The main axis direction of electric-field compulsion liquid crystal molecule makes liquid crystal molecule in this electric field, present refractive index n 0; And the electric field lines at two electric field edges will make the liquid crystal molecule of said liquid crystal layer 30 change its main axis originally, so form different refractive index n 1 at two electric field edges; But two electric field edge center, liquid crystal molecule does not receive influence and changes the main axis of liquid crystal molecule, and the refractive index here is n.Make that change of refractive is n0-n1-n-n1-n0 on the Y direction, then form refractive index gradient; When said upper surface orientation electrode 20a and said down laminar surface orientation electrode 20b are imposed the electric field of varying strength, then produce different refractive indexes in the Z direction, this can be light through the time produce zoom.

If said upper surface orientation electrode 20a and said laminar surface orientation electrode 20b symmetry down; Like Fig. 5 A and Fig. 5 B; Then the zone outside the electric field edge effect scope is less relatively, and change of refractive is approximately n0-n-n0 on the Y direction, then forms the refractive index gradient different with Fig. 4 B; When upper surface orientation electrode 20a and following laminar surface orientation electrode 20b are imposed the electric field of varying strength, then produce different refractive indexes in the Z direction, this can be and produces zoom when light passes through.

Therefore 1 use optical electric field polarization direction is different with the direction of liquid crystal molecule in the liquid crystal lens unit; And the principle of formation refractive index different (refractive index gradient); Process similar grin lens, and, make the light of incident inner in the liquid crystal lens unit through imposing different extra electric fields to change refractive index gradient; Because of making light change the conduct angle, the gradient of refractive index focuses on, shown in Fig. 6,7A, 7B, 7C.In Fig. 6, for the gradient of different refractivity, can be regarded as n layer and analyze, and observe the following relationship formula of Si Naier law (snell ' s law):

n

1cos(θ

1)=n

2cos(θ2)=…n

icos(θ

i)=…=n

ncos(θ

n)(1)

Wherein, ni is the angle of i layer light at the normal of i layer and i+1 bed interface for refractive index, the 90 °-θ i of the i layer of hypothesis.

Because liquid crystal receives electric field strong and weak different in the liquid crystal lens unit, it is different to form refractive index n i, measures but ni is difficult, and then available mean refractive index n and variations in refractive index rate α are approximate, and focal distance f then can be estimated and can be got by following formula:

Further; For the surperficial orientation electrode 20a and following laminar surface orientation electrode 20b of surperficial orientation electrode 20 on the upper strata; Can be set to symmetry or asymmetric, also can be made as the pattern of single hole shape orientation pattern, concentric circles orientation pattern or the design of other optics purposes, to cause different aperture effects.For clearly demonstrating the embodiment of utilization situation of the present invention, all use the surperficial orientation electrode 20 of single hole shape symmetry at Fig. 2,3,8 to Figure 10.

First embodiment

Consult Fig. 2, shown in 3; The basic structure of its Zoom liquid crystal lens embodiment that to be the present invention be made up of individual layer liquid crystal lens unit; The individual layer Zoom liquid crystal lens 1 of present embodiment; Start at from the thing side, comprise: single face is provided with glass substrate 10 (to call single-side electrode glass substrate 10b in the following text), the distance piece (spacer) 40 of surperficial orientation electrode 20 and is seated in single-side electrode glass substrate 10b and the liquid crystal layer 30 of distance piece 40 formed rooms and single-side electrode glass substrate 10b; Wherein, said distance piece 40 can be annular lamina or several are formed by stacking; Wherein, attaching surface orientation electrode 20 on the surface of said glass substrate 10, said surperficial orientation electrode 20 is coated with a metal film at said glass substrate 10, like aluminium, silver, or metal such as gold, selecting for use of its metal is the light-permeable metal; Said metal film if the form of said surperficial orientation electrode 20 is a single hole shape orientation pattern, then forms the aperture 11 of single hole through the etching mode moulding; Wherein, two sheet glass substrates 10 combine the back to define its gap thickness with said distance piece (spacer) 40, the thickness of promptly said liquid crystal layer 30.

Consult the gold-tinted processing procedure synoptic diagram of Fig. 8 for glass substrate 10 upper surface orientation electrodes 20; This processing procedure figure only explains the manufacturing process synoptic diagram of the glass substrate 10 (to call double-face electrode glass substrate 10a in the following text) with two-sided surperficial orientation electrode 20; And the manufacturing process of the monoplanar surface orientation electrode 20 of said single-side electrode glass substrate 10b is also similar, only on the single face of said glass substrate 10, has metal film.At first, on the surface of said glass substrate 10, plate layer of metal film 50 earlier, re-use the gold-tinted processing procedure and be etched into needed surperficial orientation electrode 20 orientation patterns with sedimentation or sputtering method; Its procedure of processing is following: establish a photoresist layer 51 in said metal film 50 outsides; Be covered with the light shield 52 of a specific orientation pattern again in said photoresist layer 51 outsides; Again through relative programs such as exposure, development, flushing and etchings to remove all the other photoresist layers and the metal film of non-said surperficial orientation electrode 20; Only keep said surperficial orientation electrode 20 pairing photoresist layer and metal films, remove photoresist layer 51 again, promptly mold surperficial orientation electrode 20.If desire to make the two-sided surperficial orientation electrode 20 of said glass substrate 10 to have symmetrical orientation pattern,, can use gold-tinted said light shield 52 when processing, and make with two-sided gold-tinted process work bench and once accomplish etching; For two-sided different surface orientation electrode 20, then use different light shield 52 respectively, can use single face to make the gold-tinted process work bench and make.

Generally speaking, unlikely too high for making operating voltage, the size of the surperficial orientation electrode 20 formed apertures 11 of single hole shape is about 2.5 to 1 with the thickness ratio of said liquid crystal layer 30, and the size of said aperture 11 can not wait to 1mm from 100 μ m; For the liquid crystal layer 30 of different-thickness, can use 40 formations of distance piece of different-thickness.The liquid crystal material that uses at present embodiment is nematic liquid crystal E7, uses the glass substrate of 1mm thickness at the glass substrate of thing side 10, uses the glass substrate 10 of 0.5mm thickness, the thickness D=120 μ m of liquid crystal layer 30 at the glass substrate 10 of picture side.

After surperficial orientation electrode 20 is imposed voltage; Can produce electric field; And then change the refractive index of said liquid crystal layer 30; Like table one and Fig. 2 .7A-7C, when desire changes the focal length of individual layer Zoom liquid crystal lens 1, then impose the voltage difference of table one in its relation of present embodiment in the surperficial orientation electrode electrode 20 of glass substrate 10 both sides.

Table one,

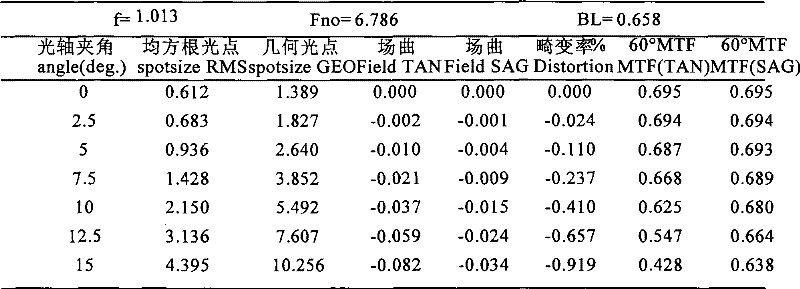

When table two to table five is four different focal; The focal distance f of individual layer Zoom liquid crystal lens 1 (mm), burnt number FNo, back focal length (BL) are (mm); For root mean square luminous point (the spot size rms under incident ray on the optical axis and each angle of optical axis included angle θ; Root-means-square μ m), geometry luminous point (GEO spot size, Geometric, μ m), the tangent line curvature of field (field TAN; Tangential field curvature), the sagitta of arc curvature of field (field SAG; Sagittal field curvature), aberration rate (distortion rate) %, in the related data of 60 ° of TAN modulation transfer functions (MTF, modulation transfer function) and 60 ° of SAG MTF, the imaging lens that can supply with devices such as camera, mobile phone camera uses.

Table two

Table three

Table four

Table five

Second embodiment

Consult shown in Figure 9, its be the present invention by double-deck liquid crystal lens unit constituted the embodiment basic structure of double-deck Zoom liquid crystal lens.The double-deck Zoom liquid crystal lens 2 of present embodiment; Start at from the thing side, comprise: single-side electrode glass substrate 10b, distance piece 40 and ground floor liquid crystal layer 30, double-face electrode glass substrate 10a, distance piece 40 and second layer liquid crystal layer 30 and single-side electrode glass substrate 10b; Wherein, between said single-side electrode glass substrate 10b and the said double-face electrode glass substrate 10a, define the thickness of two-layer liquid crystal layer 30 respectively with said distance piece 40.When incident ray after producing refraction for the first time through the ground floor liquid crystal layer of said Zoom liquid crystal lens 2 30, get into the second layer liquid crystal layer 30 of said liquid crystal lens unit 2 again, can produce refraction for the second time; Make said second layer liquid crystal layer 30 form refractive index ns 2 when control ground floor voltage makes ground floor liquid crystal layer 30 formation refractive index ns 1, control second layer voltage, can calculate the position of light focusing via formula (2); In like manner be used on the devices such as camera or mobile phone camera, on the zoom demand for different focal,, can reaching Zoom effect, can save many spaces compared to conventional lenses multi-disc composite module as long as control ground floor voltage and second layer voltage produce coupling.

For convenience of explanation, in the present embodiment, adopt as first and implement identical liquid crystal layer 30, the distance piece 40 of same thickness, identical material and the glass substrate 10 of thickness, surperficial orientation electrode 20 etc.; For reaching overall focal length is 0.866mm; Then ground floor liquid crystal layer 30 (i.e. the first liquid crystal lens unit) being imposed 2.15V voltage makes it produce that focal length is 1.111mm, second layer liquid crystal layer 30 (i.e. the second liquid crystal lens unit) is imposed 1.49V voltage, and to make its generation focal length be 2.525mm; Table six is for when the present embodiment focal length is 0.866mm; For the root mean square luminous point under incident ray on the optical axis and each angle of optical axis included angle θ, how much luminous points, the tangent line curvature of field, the sagitta of arc curvature of field, aberration rate %, in the related data of 60 ° of TAN modulation transfer functions and 60 ° of SAG MTF, can supply with the imaging lens use of devices such as camera, mobile phone camera.

Table six

When being 0.746mm, then ground floor liquid crystal layer 30 (i.e. the first liquid crystal lens unit) being imposed 1.74V voltage and make it produce that focal length is 1.720mm, second layer liquid crystal layer 30 (i.e. the second liquid crystal lens unit) is imposed 2.31V voltage, and to make its generation focal length be 1.013mm for zoom to overall focal length.Table seven is for when the present embodiment focal length is 0.746mm; For the root mean square luminous point under incident ray on the optical axis and each angle of optical axis included angle θ, how much luminous points, the tangent line curvature of field, the sagitta of arc curvature of field, aberration rate %, in the related data of 60 ° of TAN modulation transfer functions and 60 ° of SAG MTF, can supply with the imaging lens use of devices such as camera, mobile phone camera.

Table seven

The 3rd embodiment

Consult shown in Figure 10, its be the present invention by three layers of liquid crystal lens unit constituted the embodiment basic structure of three layers of Zoom liquid crystal lens 3.Three layers of Zoom liquid crystal lens 3 of present embodiment; Start at from the thing side, comprise: single-side electrode glass substrate 10b, distance piece 40 and ground floor liquid crystal layer 30, double-face electrode glass substrate 10a, distance piece 40 and second layer liquid crystal layer 30, double-face electrode glass substrate 10a, distance piece 40 and the 3rd layer of liquid crystal layer 30 and single-side electrode glass substrate 10b; Between said single-side electrode glass substrate 10b and the said double-face electrode glass substrate 10a, define the thickness of three layers of liquid crystal layer 30 respectively with said distance piece 40.After the ground floor liquid crystal layer 30 generations for the first time refraction of incident ray at the said three layers of Zoom liquid crystal lens 3 of process; The second layer liquid crystal layer 30 that gets into said Zoom liquid crystal lens 3 again produces refraction for the second time, and the 3rd layer of liquid crystal layer 30 that gets into said liquid crystal lens unit 3 again produces refraction for the third time; Said ground floor liquid crystal layer 30 formation refractive index ns 1, control second layer voltage make said second layer liquid crystal layer 30 form refractive index ns 2, the 3rd layer of voltage of control makes said the 3rd layer of liquid crystal layer 30 form refractive index n 3 when control ground floor voltage makes, and can calculate the position of light focusing via formula (2); In like manner be used on the devices such as camera or mobile phone camera; On the zoom demand for different focal; As long as control ground floor voltage, second layer voltage and the 3rd layer of voltage produce coupling, can reach Zoom effect, can save many spaces compared to conventional lenses multi-disc composite module.

By on can know that the present invention has the following advantages at least:

(1), Zoom liquid crystal lens of the present invention, do zoom action with liquid crystal lens unit 10, need not add the mechanics mobile mechanism, integral module can be done more compactly.

(2), Zoom liquid crystal lens of the present invention, use surperficial orientation electrode 20 structures of aluminium film other suitable printing opacity metals such as (or) silverskin to replace existing ITO electrode between every layer of liquid crystal layer 30, can reduce cost.

(3), Zoom liquid crystal lens of the present invention; Wherein the surperficial orientation electrode 20 of liquid crystal lens unit can be designed by different alignment patterns such as single hole shape, concentric circles; Different electric field pattern through surperficial orientation electrode 20 generations; Can produce different aperture size effects, become Zoom liquid crystal lens through single or multiple lift liquid crystal lens unit combination again, can constitute the zoom lens of practical camera, mobile phone camera or image processor.

More than explanation is just illustrative for the purpose of the present invention, and nonrestrictive, those of ordinary skills understand; Under the situation of spirit that does not break away from following accompanying claims and limited and scope, can make many modifications, change; Or equivalence, but all will fall in protection scope of the present invention.

Claims (3)

1. Zoom liquid crystal lens, it comprises individual layer liquid crystal lens unit; The glass substrate of two predetermined thickness of said individual layer liquid crystal lens unit by using; Process single-side electrode glass substrate or double-face electrode glass substrate; Again two plate electrode glass substrates are arranged in parallel with preset space length through distance piece, make the room space that forms one deck predetermined thickness between the two plate electrode glass substrates supply to seal liquid crystal up for safekeeping and constitute to form a liquid crystal layer; It is characterized in that:

Said single-side electrode glass substrate or said double-face electrode glass substrate are provided with surperficial orientation electrode; Said surperficial orientation electrode is for being provided with the aluminium or the silver metal film of a light-permeable on the surface of said glass substrate; Form predetermined single hole shape orientation pattern with the formation aperture through etching mode again, and the electrode on each glass electrode substrate is controlled independently to impose the voltage of varying strength respectively;

Surperficial orientation electrode on the said glass baseplate surface is on the surface of said glass substrate, to plate layer of metal film with sedimentation or sputtering method earlier; On said metal film, be coated with a photoresist layer again; On said photoresist layer, be covered with the mask layer of a specific orientation pattern again; Again through develop, etching program to be removing the photoresist layer and the metal film of non-electrode part, and keeps the photoresist layer and the metal film of electrode part, remove photoresist layer again and form;

When the surperficial orientation electrode to two glass electrode substrates imposes specific voltage, in the liquid crystal layer of regulation and control liquid crystal lens unit the row of liquid crystal molecule to, and then produce specific refractive index gradient, wherein,

The surperficial orientation electrode of said metal etch is identical material, symmetry on glass substrate is two-sided and forms identical orientation pattern;

Wherein, the thickness ratio of formed diaphragm diameter of single hole shape orientation pattern and liquid crystal layer is about 2.5.

2. a Zoom liquid crystal lens comprises double-deck liquid crystal lens unit; The glass substrate of three predetermined thickness of said double-deck liquid crystal lens unit by using; Process single-side electrode glass substrate or double-face electrode glass substrate; Again said three plate electrode glass substrates are arranged in parallel with preset space length through distance piece, make the room space that forms one deck predetermined thickness between adjacent two glass electrode substrates respectively supply to seal liquid crystal up for safekeeping and constitute to form two-layer liquid crystal layer; It is characterized in that:

Said single-side electrode glass substrate or said double-face electrode glass substrate are provided with surperficial orientation electrode; Said surperficial orientation electrode is for being provided with the aluminium or the silver metal film of a light-permeable on the surface of said glass substrate; Form predetermined single hole shape orientation pattern with the formation aperture through etching mode again, and the electrode on each glass electrode substrate is controlled independently to impose the voltage of varying strength respectively;

Surperficial orientation electrode on the said glass baseplate surface is on the surface of said glass substrate, to plate layer of metal film with sedimentation or sputtering method earlier; On said metal film, be coated with a photoresist layer again; On said photoresist layer, be covered with the mask layer of a specific orientation pattern again; Again through develop, etching program to be removing the photoresist layer and the metal film of non-electrode part, and keeps the photoresist layer and the metal film of electrode part, remove photoresist layer again and form;

When the surperficial orientation electrode to adjacent two glass electrode substrates imposes specific voltage, the row who regulates and control liquid crystal molecule in the liquid crystal layer of each layer liquid crystal lens unit to, and then produce specific refractive index gradient, wherein,

The surperficial orientation electrode of said metal etch is identical material, symmetry on glass substrate is two-sided and forms identical orientation pattern;

Wherein, the thickness ratio of formed diaphragm diameter of single hole shape orientation pattern and liquid crystal layer is about 2.5.

3. a Zoom liquid crystal lens comprises that the liquid crystal lens unit constitutes more than three layers; The said glass substrate of four above predetermined thickness of liquid crystal lens unit by using more than three layers; Process single-side electrode glass substrate or double-face electrode glass substrate; Again said each glass electrode substrate is arranged in parallel with preset space length through distance piece, makes the room space that forms one deck predetermined thickness between adjacent two glass electrode substrates respectively supply to seal liquid crystal up for safekeeping and constitute to form liquid crystal layer more than three layers; It is characterized in that:

Said single-side electrode glass substrate or said double-face electrode glass substrate are provided with surperficial orientation electrode; Said surperficial orientation electrode is for being provided with the aluminium or the silver metal film of a light-permeable on the surface of said glass substrate; Form predetermined single hole shape orientation pattern with the formation aperture through etching mode again, and the electrode on each glass electrode substrate can be controlled independently to impose the voltage of varying strength respectively;

Surperficial orientation electrode on the said glass baseplate surface is on the surface of said glass substrate, to plate layer of metal film with sedimentation or sputtering method earlier; On said metal film, be coated with a photoresist layer again; On said photoresist layer, be covered with the mask layer of a specific orientation pattern again; Again through develop, etching program to be removing the photoresist layer and the metal film of non-electrode part, and keeps the photoresist layer and the metal film of electrode part, remove photoresist layer again and form;

When the surperficial orientation electrode to adjacent two glass substrates imposes specific voltage, regulate and control in the liquid crystal layer of each layer liquid crystal lens unit in liquid crystal molecule row to, and then produce specific refractive index gradient, wherein,

The surperficial orientation electrode of said metal etch is symmetry on glass substrate is two-sided and forms identical orientation pattern;

Wherein, the thickness ratio of formed diaphragm diameter of single hole shape orientation pattern and liquid crystal layer is about 2.5.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2008102123513A CN101672990B (en) | 2008-09-10 | 2008-09-10 | Zoom liquid crystal lens |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2008102123513A CN101672990B (en) | 2008-09-10 | 2008-09-10 | Zoom liquid crystal lens |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN101672990A CN101672990A (en) | 2010-03-17 |

| CN101672990B true CN101672990B (en) | 2012-04-25 |

Family

ID=42020284

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2008102123513A Expired - Fee Related CN101672990B (en) | 2008-09-10 | 2008-09-10 | Zoom liquid crystal lens |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN101672990B (en) |

Families Citing this family (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP5667928B2 (en) * | 2011-05-20 | 2015-02-12 | 株式会社ジャパンディスプレイ | Image display device |

| CN104081260B (en) * | 2012-01-30 | 2016-11-09 | 日本电气硝子株式会社 | Liquid crystal lens and liquid crystal lens structure cell |

| CN102749769A (en) * | 2012-07-16 | 2012-10-24 | 四川大学 | 2D/3D switchable free stereo display device based on double-layer liquid crystal lenses |

| TWI494599B (en) * | 2014-03-12 | 2015-08-01 | Silicon Touch Tech Inc | Optical zoom structure |

| CN105334691A (en) * | 2015-12-15 | 2016-02-17 | 深圳市时代华影科技股份有限公司 | High-light-effect 3D system adaptable to various sizes of projection halls |

| KR101822895B1 (en) | 2016-04-07 | 2018-01-29 | 엘지전자 주식회사 | Driver assistance apparatus and Vehicle |

| CN105842888A (en) * | 2016-05-31 | 2016-08-10 | 成都微晶景泰科技有限公司 | Quick focusing optical element and imaging device |

| CN105867011B (en) * | 2016-06-27 | 2019-02-05 | 京东方科技集团股份有限公司 | A kind of display panel and display device |

| CN108267896A (en) * | 2016-12-30 | 2018-07-10 | 深圳超多维光电子有限公司 | polarization imaging device and method |

| CN108717235A (en) * | 2018-08-29 | 2018-10-30 | 深圳珑璟光电技术有限公司 | A kind of nearly eye of adjustable diopter waveguide shows Optical devices |

| CN110082982A (en) * | 2019-05-27 | 2019-08-02 | 北京航空航天大学 | A kind of liquid crystal lens array of simple electrode structure |

| CN110149466A (en) * | 2019-05-31 | 2019-08-20 | 深圳前海达闼云端智能科技有限公司 | Optical filtering variable focus package, camera module and terminal |

| TW202127121A (en) * | 2020-01-13 | 2021-07-16 | 點晶科技股份有限公司 | Mobile communication apparatus and aperture module |

| CN112099285B (en) * | 2020-11-03 | 2021-02-02 | 南昌虚拟现实研究院股份有限公司 | Liquid crystal lens device and virtual reality zooming method |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1688783A1 (en) * | 2003-11-27 | 2006-08-09 | Asahi Glass Company Ltd. | Optical element using liquid crystal having optical isotropy |

| CN1914674A (en) * | 2004-02-03 | 2007-02-14 | 旭硝子株式会社 | Liquid crystal lens element and optical head device |

| CN101040336A (en) * | 2004-10-19 | 2007-09-19 | 旭硝子株式会社 | Liquid crystal diffractive lens element and optical head device |

-

2008

- 2008-09-10 CN CN2008102123513A patent/CN101672990B/en not_active Expired - Fee Related

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1688783A1 (en) * | 2003-11-27 | 2006-08-09 | Asahi Glass Company Ltd. | Optical element using liquid crystal having optical isotropy |

| CN1914674A (en) * | 2004-02-03 | 2007-02-14 | 旭硝子株式会社 | Liquid crystal lens element and optical head device |

| CN101040336A (en) * | 2004-10-19 | 2007-09-19 | 旭硝子株式会社 | Liquid crystal diffractive lens element and optical head device |

Also Published As

| Publication number | Publication date |

|---|---|

| CN101672990A (en) | 2010-03-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101672990B (en) | Zoom liquid crystal lens | |

| Ren et al. | Switchable focus using a polymeric lenticular microlens array and a polarization rotator | |

| US20100053539A1 (en) | Liquid crystal lens with variable focus | |

| TW438993B (en) | Liquid display device and method for making the same | |

| TW594155B (en) | Optical interference type color display and optical interference modulator | |

| KR100863571B1 (en) | Display pixel using electro active polymer and display employing the same | |

| US20110235181A1 (en) | Optical film, antireflection optical element and master | |

| JP2007219526A5 (en) | ||

| WO2018045812A1 (en) | Lens device | |

| CN102566191B (en) | Liquid crystal lens structure and driving method thereof | |

| JP2006201782A (en) | Wire grid polarization film, method for manufacturing the same, liquid crystal display using the same, and method for manufacturing mold for forming grid of the same | |

| TW201033640A (en) | Electrowetting display devices | |

| KR20020085842A (en) | Reflective liquid-crystal display device | |

| CN103109213A (en) | Light-diffusing element, polarizing plate having light-diffusing element attached thereto, polarizing element, and liquid crystal display device equipped with those components | |

| TW200413787A (en) | Optical interference type reflection panel and the manufacturing method thereof | |

| WO2017148010A1 (en) | Liquid crystal display and electronic apparatus | |

| CN103217832A (en) | Color filter, manufacturing method and displaying device of color filter | |

| CN107357130B (en) | Mask plate, lens array, preparation method of lens array and display panel | |

| WO2019085077A1 (en) | Liquid crystal lens and 3d display device | |

| TWM594163U (en) | Refective cholesteric liquid crystal display | |

| CN104571721B (en) | A kind of transparent conductive oxide pattern blanking structure, touch panel and display device | |

| CN104280932A (en) | Display panel and display device | |

| Li et al. | Low voltage liquid crystal microlens array based on polyvinyl alcohol convex induced vertical alignment | |

| CN101261384A (en) | Polymer dispersed LCD door mirror compound film and method of manufacture | |

| CN110383115A (en) | Liquid lens, camera model and Optical devices |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20120425 Termination date: 20120910 |