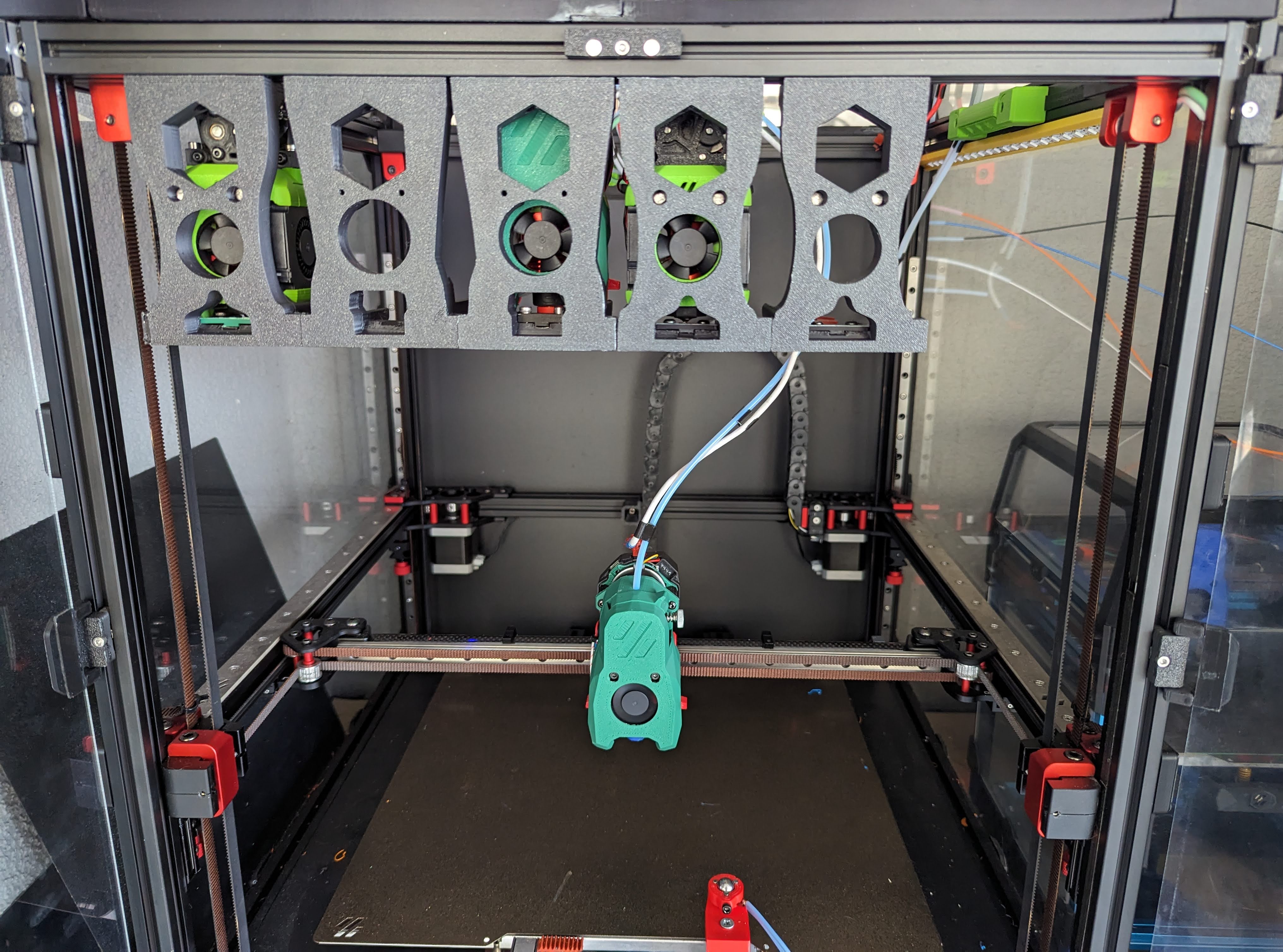

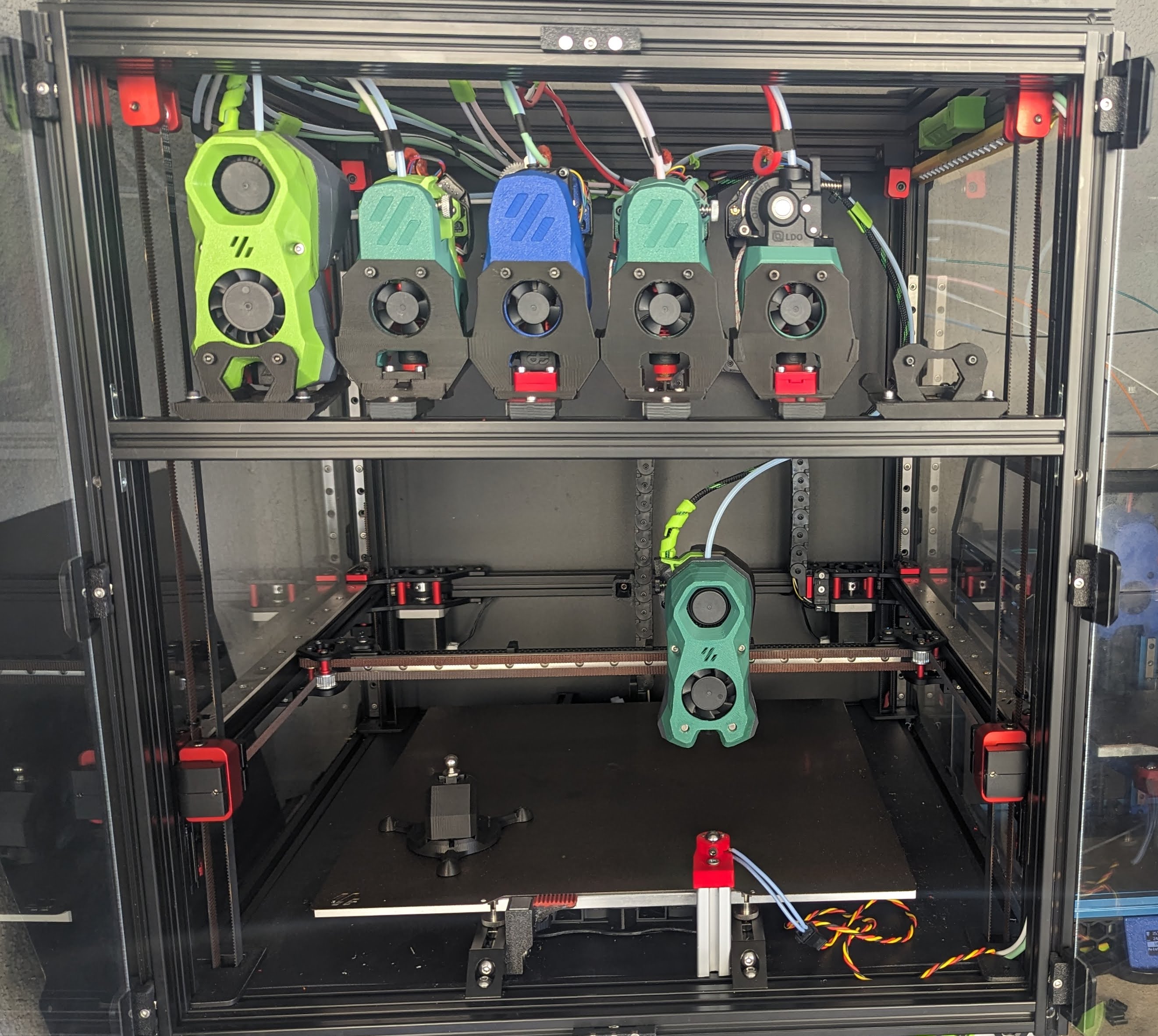

The dock comes in two versions - cross beam mounted or top mounted.

| Top mounted | Cross beam |

|---|---|

| * Can be installed in existing frame * Best clearance |

* Supports Full sized Stealthburner * Extra docking latch |

|

|

|

|

- High temp silicone for the nozzle pad

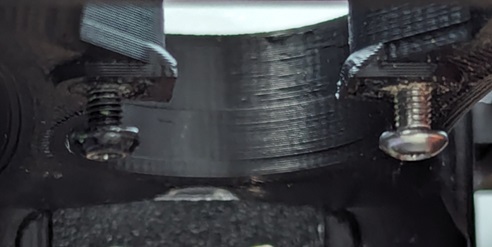

- 35 mm of 7x0.1mm springsteel, salvageable from 1m tape measure.

- some M3 screws and heatset inserts

- retnetion hardware - see below

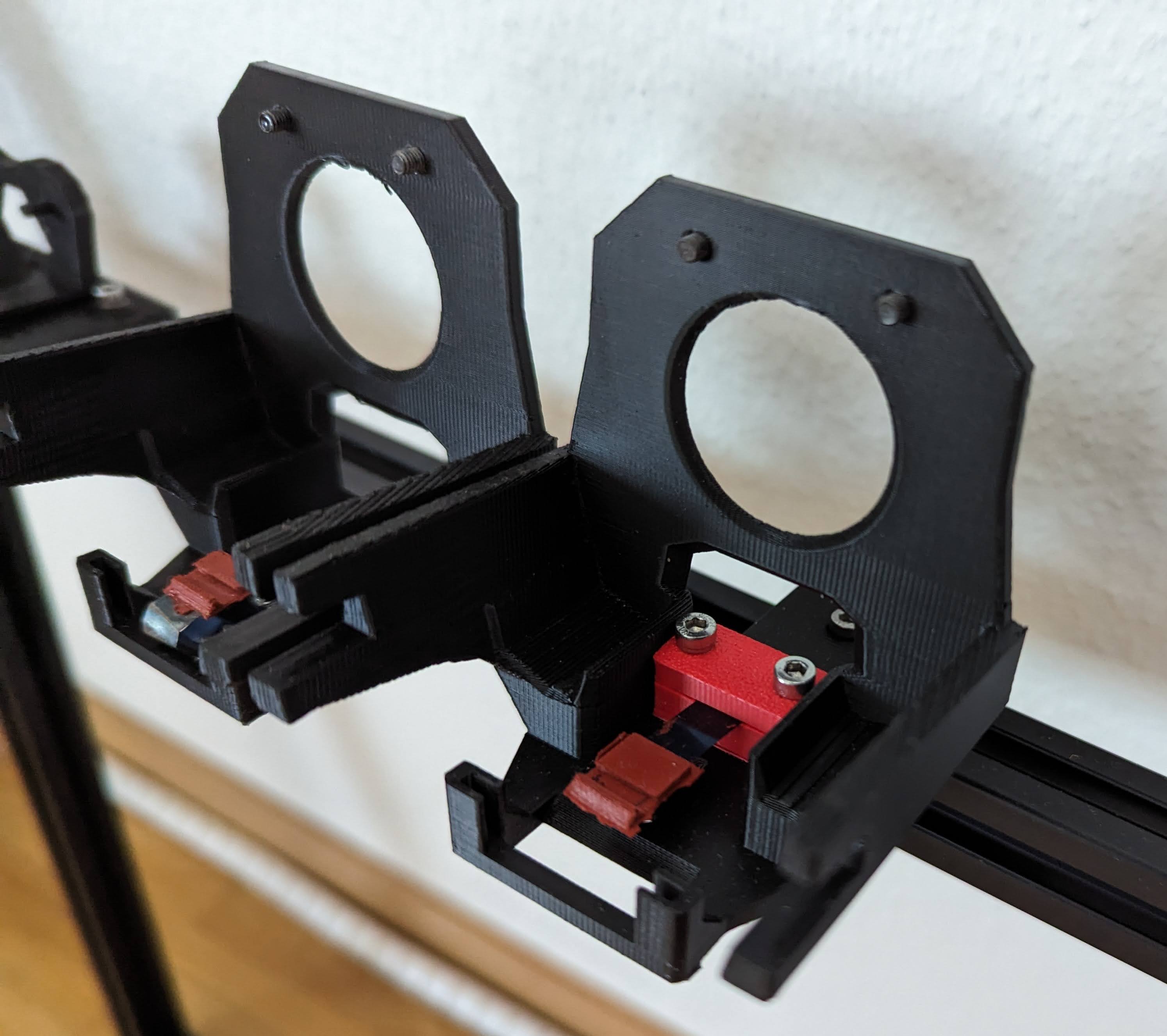

There are 3 versions of retentiom mechanism, this will likely converge as I get more relibility data

You will need:

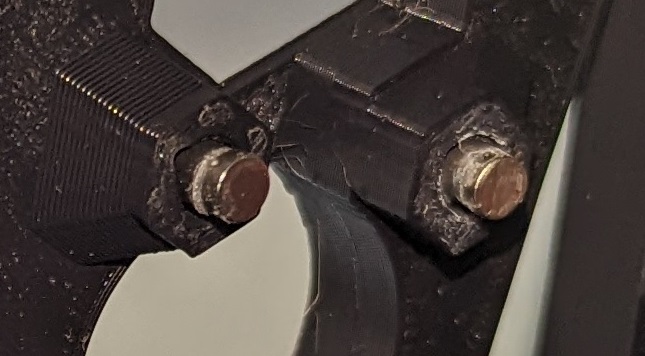

- 2x 5x2mm round magnets

- 2x m3 x 10 steeel screws in the dock - steel (magnetic)

- the screws in toolhead also need to be seel to stick to the magnets

Stealthburner and mini stelathburner on cross beam uses this approach. It relies on the bottom pin as the main retention mechanism and the magnet is just to prevent it rattling around.

Drop the magnets on the screw heads in the toolhead. They will stay there on their own, no glue required.

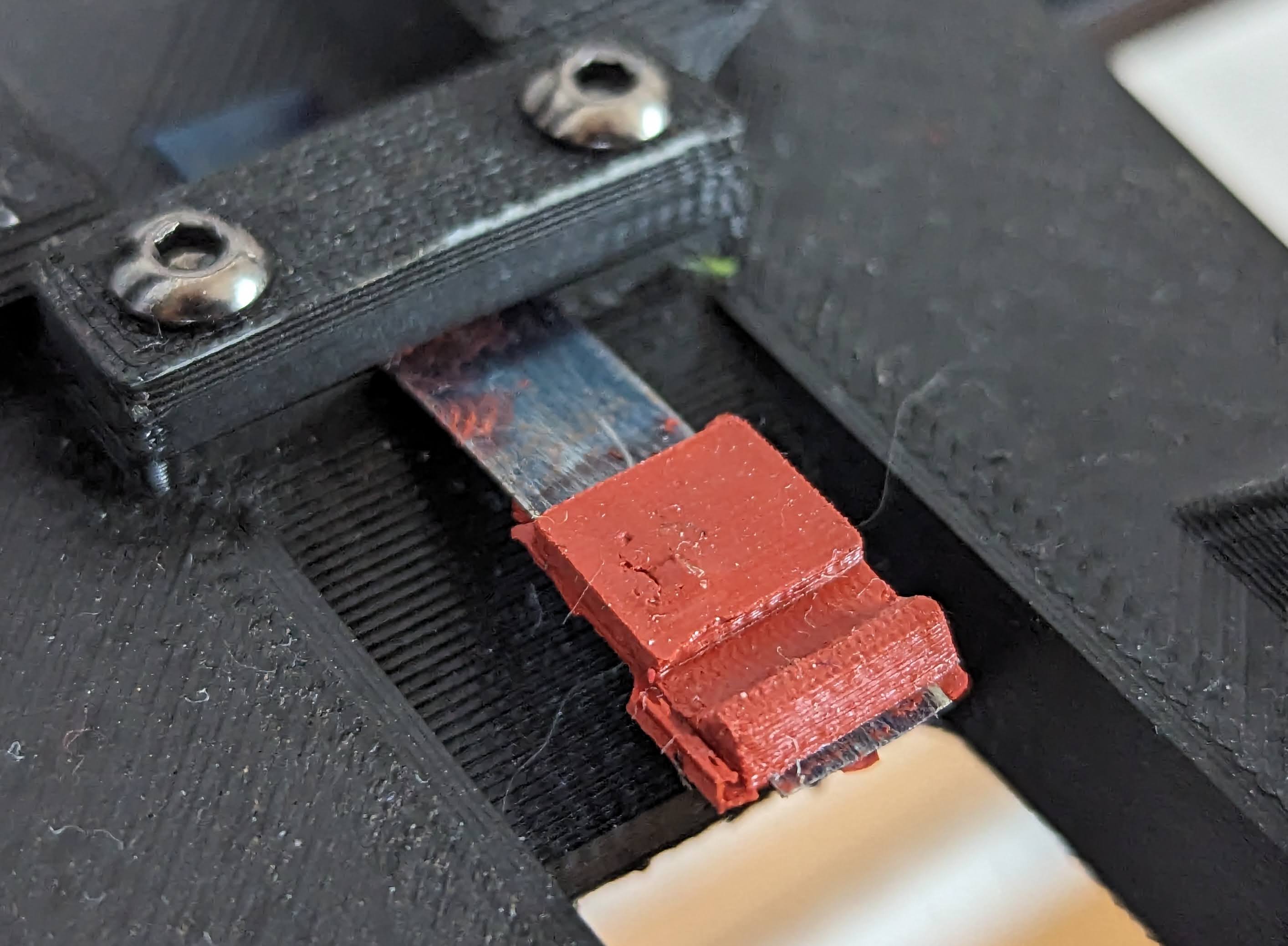

The toolhead hooks on to the M3 scew heads. Just need 2x m3x10 butthonhead screws.

You will need:

- 2x 5x2-3mm round magnets - make sure you get quality magnets cheap aliexpress ones are not srong enough

- 2x 5x10 steeel steel rod - use the cutting jig to cut to size

- the screws in toolhead also need to be seel to stick to the magnets

There are no bottom pins on the top mounted docks, so the magnets are doing most of the holding. The magnets are superglued to the steel rods.

Essentially you need to build this. The exact dimensions depend on your printer size.

Print the nozzle pad mold. Put on some mold release, just rubbing with a birthday candle works well.

Cut a 35mm piece of springsteel and mold the silicone pad on one end. The mount is designed to accomodate fror the springteel curve, place it so that it curves downwards.