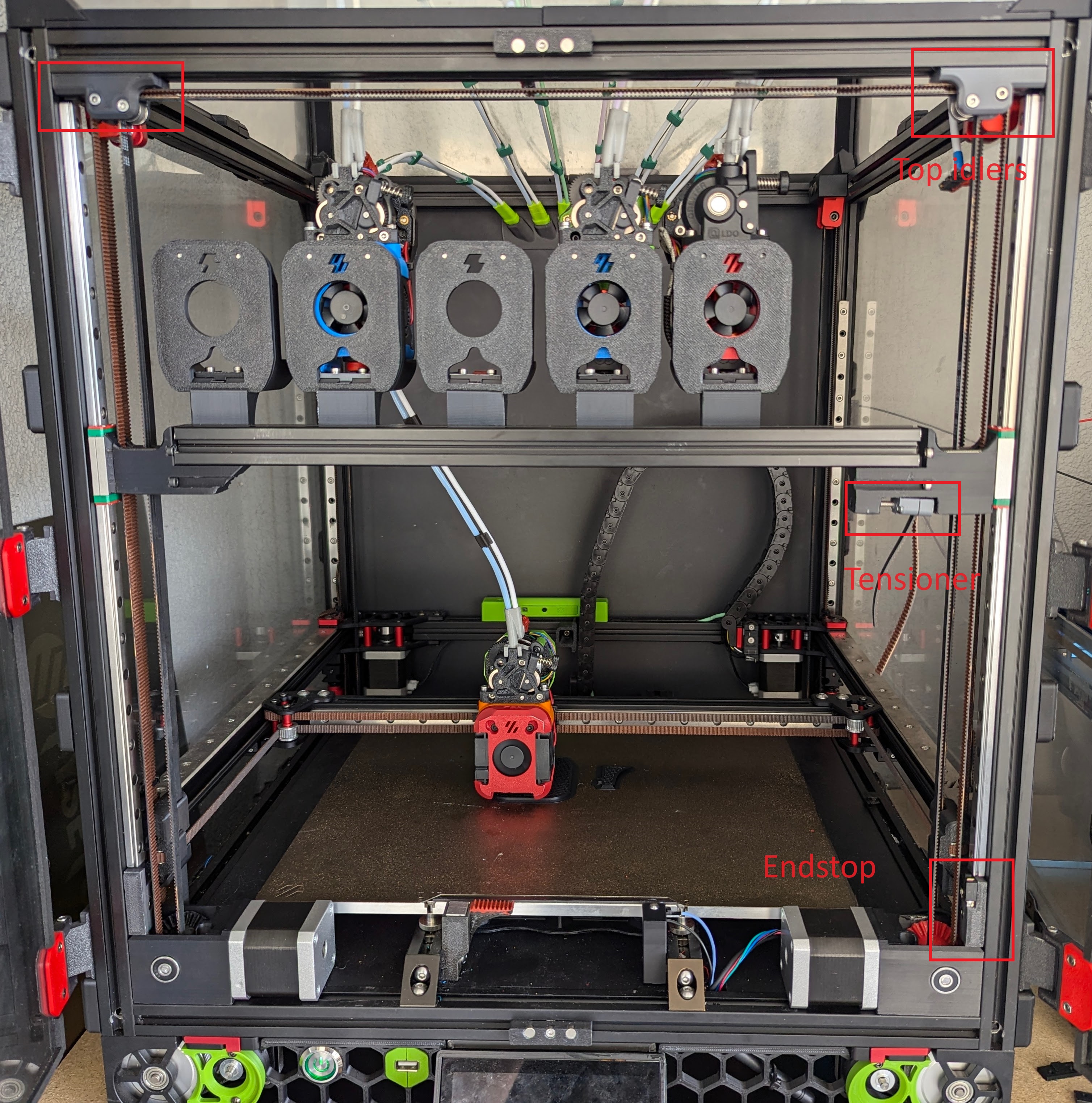

A motorized crossbar - compatible with Trident and V2.

For up to 3 toolheads (2 docked), a single motor is sufficient. For more, I recommend two motors.

2020 Extrusion:

- 279mm long for 250mm build

- 329mm long for 300mm build

- 379mm long for 350mm build

XY Idlers:

- 2x 20mm 5mm shaft

- 4x heatset inserts

- 4x 8mm m3 screw

- existing pulleys

Common:

- Omron d2f endstop switch

- ~4m 6mm GT2 belt (for 350 size)

- m3 bolts, heatset inserts, nuts

- 8x 8mm m4 bolts, t-nuts

- 8x F623RS flanged bearings (voron 0 spec)

Voron 2.4:

- 2x MGN9H rails, same length as your Z rails

Voron Trident:

- 2x MGN9H rails, 210mm+

For Single motor:

- nema 17 motor

- 36mm 5mm shaft

- 2x 625 bearing (voron 2 spec)

- 20T GT2 idler

- 20T GT2 pulley

- 2x 5x1mm washers

For dual motor:

- 2x nema 17 motor

- 2x 36mm 5mm shaft

- 4x 625 bearing (voron 2 spec)

- 2x 20T GT2 pulley

- 4x 5x1mm washers

- Assemble and replace the the XY idlers

- Install the Top idlers

- Install the linear rails, make sure they clear the XY idlers

- Install endstop

- Assemble and connect the gearboxes

- Assemble the gantry

- Install the belt

- Adjust the belt so that the gantry is ~horizontal

- Tension the belt

- Test the lifbar movement

Work in progress...

The assembly sequence is a bit tricky.

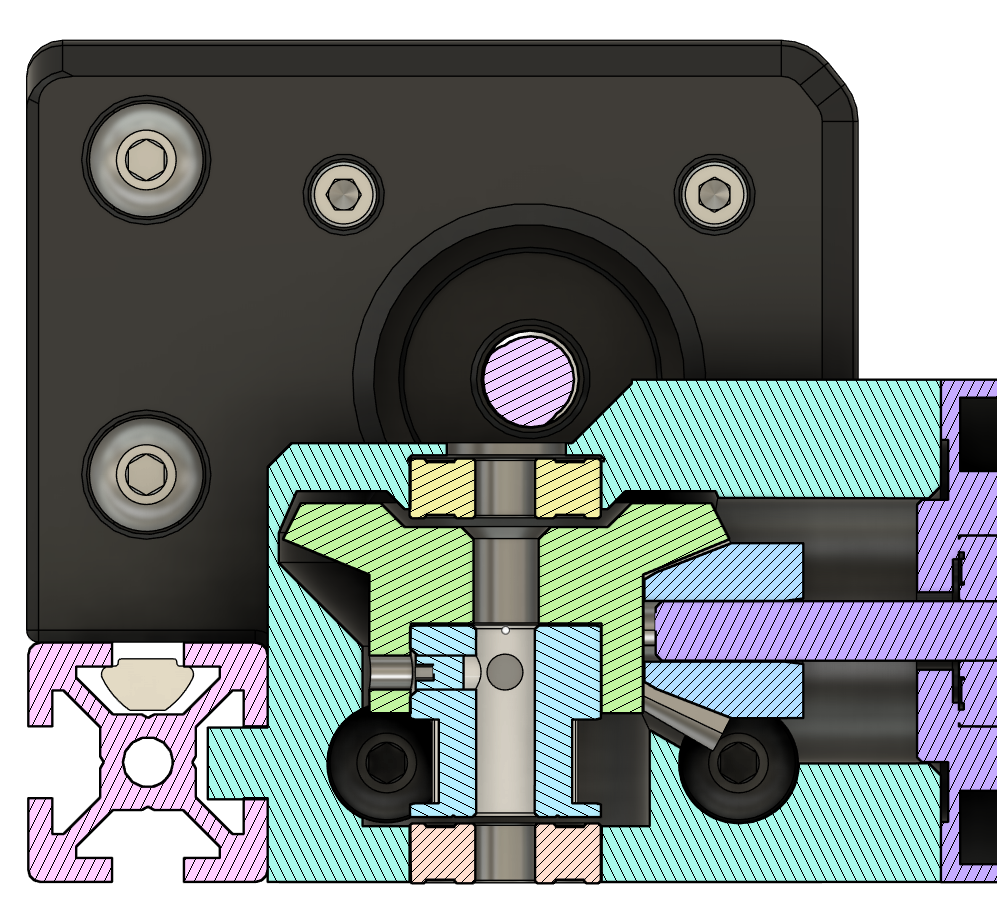

- First mount the gears - small on the stepper axis and large on the pulley. Use the grubscrews in reverse to tighten the large gear. The small gear is just friction fit.

- Then install the m3 screws for the motor, do not mount the motor yet.

- Then press fit in the rear bearing, this needs quite some force, use a rod or hex wrench through the front hole to push it in.

- Install the Left side M4 screw, but not the right one.

- Install the big gear, this is a bit tricky:

- Push in the shaft through the bearing from back, have it extend 1mm inside.

- Place the washer on the shaft

- Push the gear assembly down from above, it's a right fit, but should go in without much force.

- Push the shaft all the way through

- Add the second washer and bearing.

- Install the motor, test if the gears mesh smoothly

- Install the remaing 2 M4 screws.

Cross cut vs Trident leadscrew:

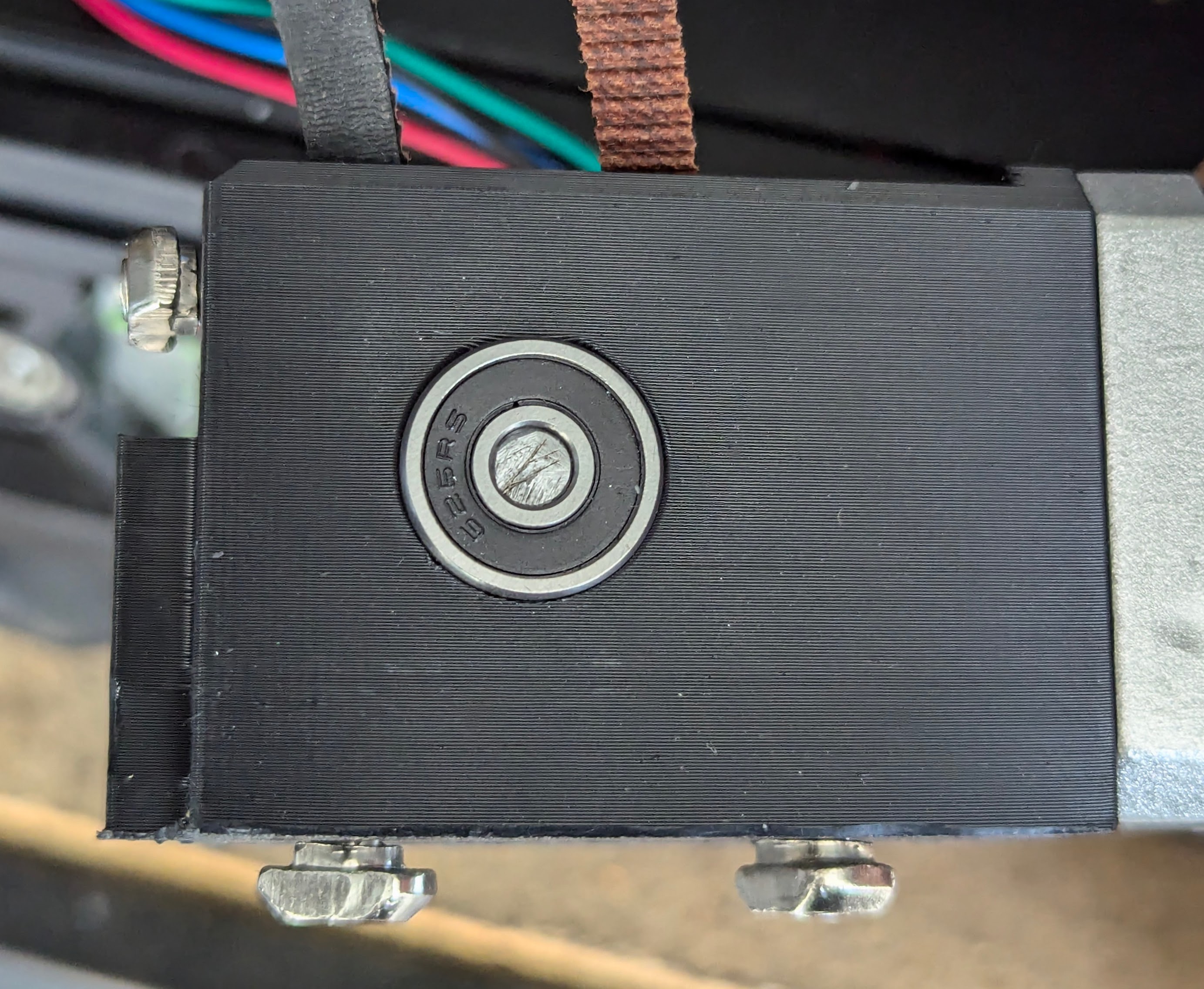

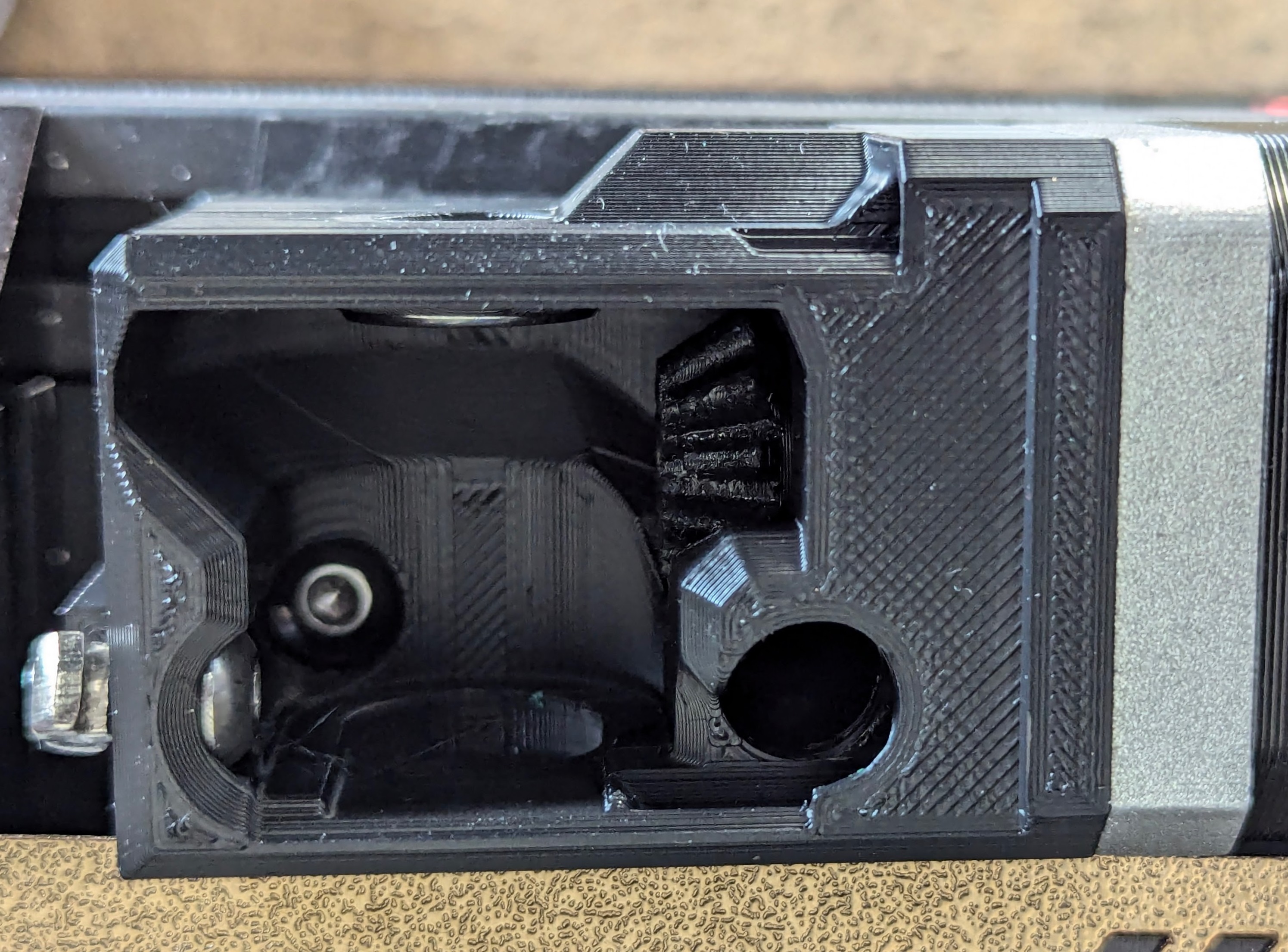

Top down, test fitting the Motor, remove the motor to install the large gear.

Finished, ready to be mounted:

See toolchanger-lifbar.cfg in Klipper folder.